Electrode preparation technology of super capacitor

A supercapacitor and preparation process technology, applied in the field of capacitors, can solve the problems of removing, limiting the application of supercapacitors, supercapacitor cell capacity, and limiting the performance parameters of cycle life, so as to reduce the energy consumption of products and simplify the drying process. , the effect of a wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

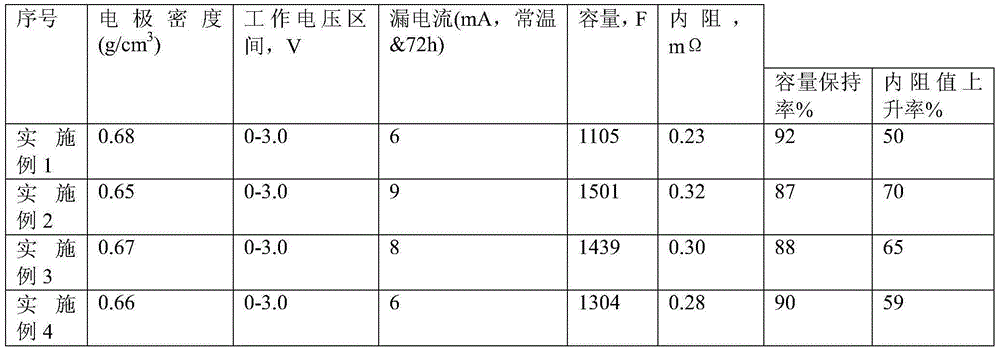

Examples

Embodiment 1

[0031] A kind of supercapacitor electrode preparation process, described preparation process comprises the steps:

[0032] a) Weigh the raw materials according to the following mass percentages: 5% conductive agent, 5% binder polytetrafluoroethylene powder, 90% active material high specific surface area activated carbon; the conductive agent is composed of 3 parts of conductive carbon black and 1 part of graphene mixture;

[0033] b) After the weighing is completed, the powdered activated carbon, the binder polytetrafluoroethylene powder, and the conductive agent are uniformly mixed according to the dry powder, and after mixing for 2 hours, the obtained solid mixture is heated under the action of a super shearer , the temperature is 80°C, shear deformation mixing is carried out, and then the above-mentioned solid mixture is rolled vertically and horizontally respectively to obtain a dry carbon film; the thickness of the dry carbon film is 100 microns;

[0034] c) After pre-sp...

Embodiment 2

[0037] A kind of supercapacitor electrode preparation process, described preparation process comprises the steps:

[0038] a) Take the raw materials by the following mass percentages: 8% conductive agent, 8% binder polytetrafluoroethylene powder, 84% active material high specific surface area activated carbon; the conductive agent is 2 parts of conductive carbon black, 1 part of graphene, 1 part of three-dimensional mixed conductive agent composed of carbon nanotubes;

[0039] b) After the weighing is completed, the powdered activated carbon, the binder polytetrafluoroethylene powder, and the conductive agent are uniformly mixed according to the dry powder, and after mixing for 3 hours, the obtained solid mixture is heated under the action of a super shearer , the temperature is 100°C, shear deformation mixing is carried out, and then the above-mentioned solid mixture is rolled vertically and horizontally respectively to obtain a dry carbon film; the thickness of the dry carbo...

Embodiment 3

[0043] A kind of supercapacitor electrode preparation process, described preparation process comprises the steps:

[0044] a) Weigh raw materials according to the following mass percentages: 10% conductive agent, 10% binder polytetrafluoroethylene powder, 80% active material high specific surface area activated carbon; the conductive agent is composed of 5 parts of conductive carbon black and 2 parts of graphene mixture;

[0045] b) After the weighing is completed, the powdered activated carbon, the binder polytetrafluoroethylene powder, and the conductive agent are uniformly mixed according to the dry powder, and after mixing for 5 hours, the obtained solid mixture is heated under the action of a super shearer , the temperature is 120°C, shear deformation mixing is carried out, and then the above-mentioned solid mixture is rolled vertically and horizontally respectively to obtain a dry carbon film; the thickness of the dry carbon film is 140 microns;

[0046] c) After pre-sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com