Battery core and fabrication method thereof

一种电芯、层叠方向的技术,应用在电芯及其制备领域,能够解决锂离子电导率小、锂离子电池倍率性能差等问题,达到层叠结构设置简单、改善电化学性能和安全性能、便于大规模生产的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

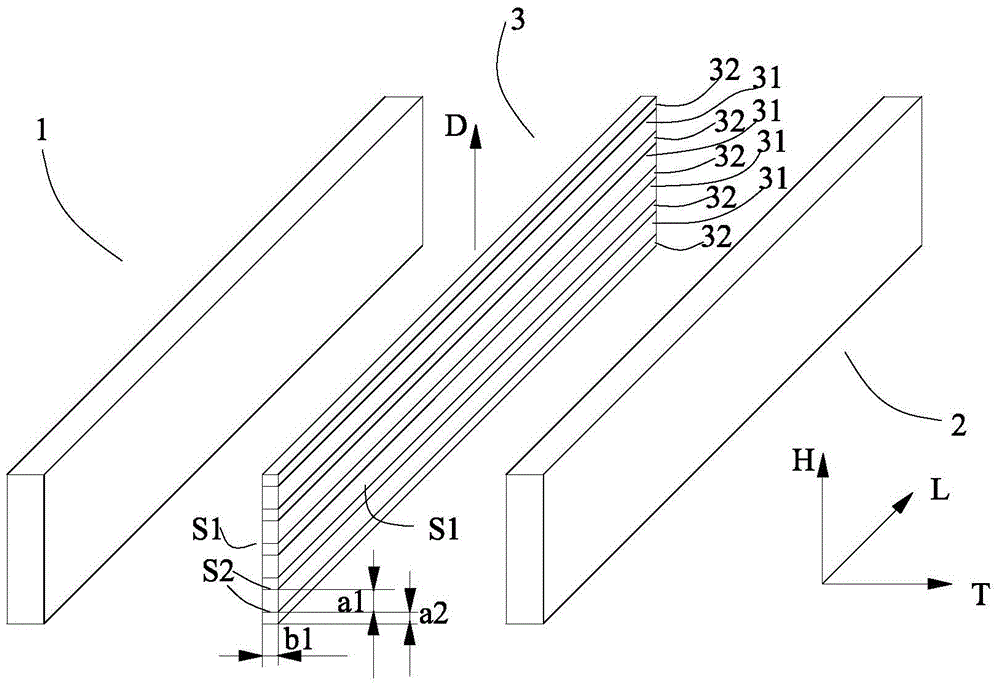

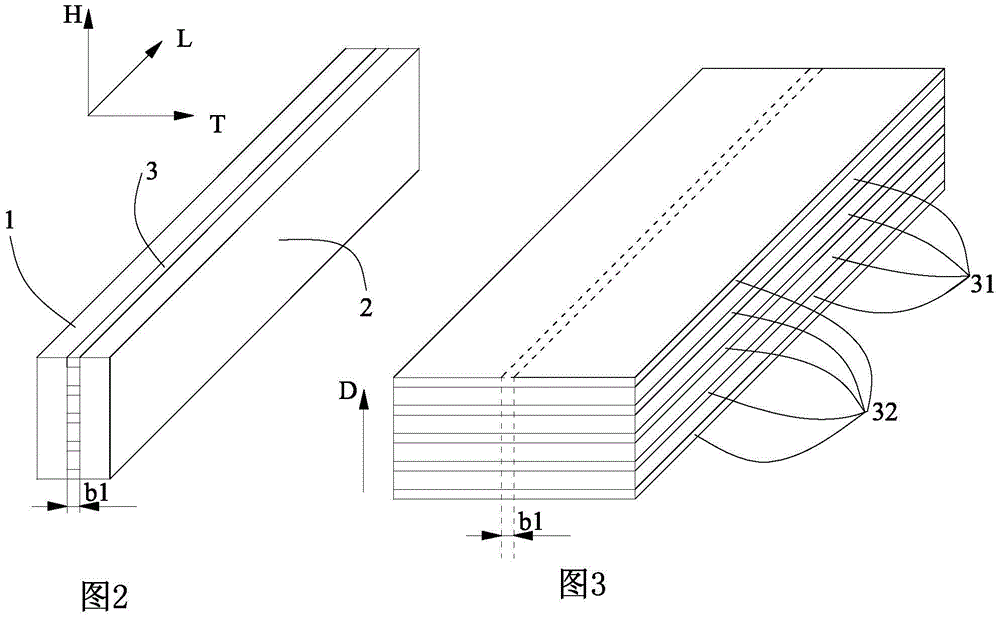

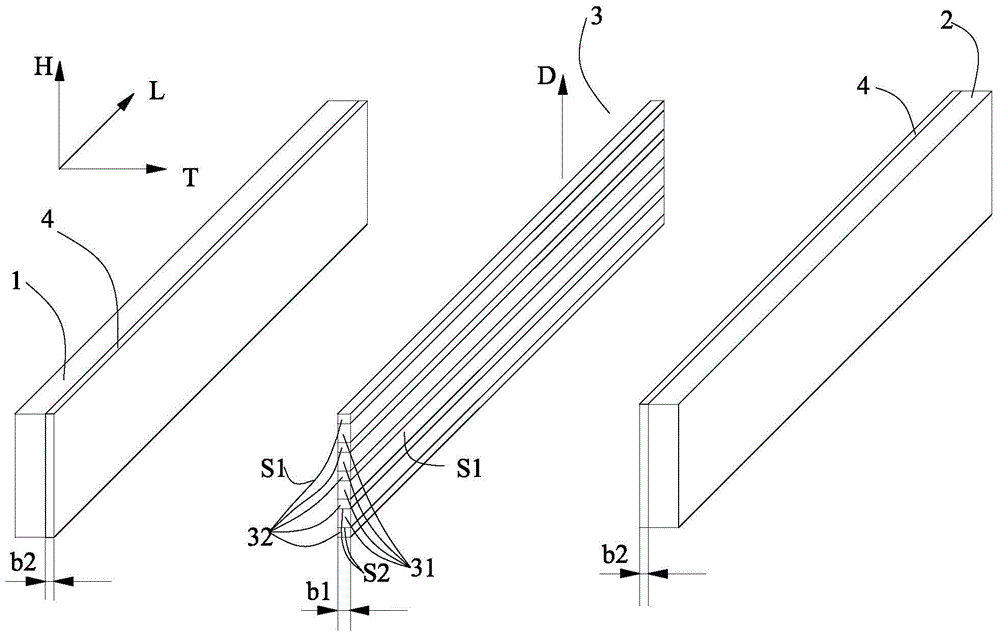

[0072] refer to Figure 1-14 , according to the preparation method of the electric core of the second aspect of the present invention, for preparing the electric core according to the first aspect of the present invention, comprising the steps of: providing a positive electrode sheet 1; providing a negative electrode sheet 2; preparing a composite solid electrolyte membrane 3: by Alternately depositing inorganic solid electrolyte layers 31 and structural support layers 32 on a substrate (not shown) along the lamination direction D to prepare a composite solid electrolyte material with a sequentially staggered lamination structure, and separate the composite solid electrolyte material from the substrate to obtain A composite solid electrolyte membrane 3, wherein the composite solid electrolyte membrane 3 includes an inorganic solid electrolyte layer 31 and a structural support layer 32 that are sequentially stacked along the stacking direction D; to prepare a cell: the composite...

Embodiment 1

[0085] (1) Provide positive electrode sheet

[0086] The active material lithium cobaltate (LiCoO 2 ), the binder polyvinylidene fluoride (PVDF), and the conductive agent conductive carbon are added to the solvent N-methylpyrrolidone (NMP) in a mass ratio of 95:3:2 and mixed evenly to make a positive electrode slurry, wherein the solid of the positive electrode slurry The content is 40%, and then the positive electrode slurry is evenly coated on both sides of the 12 μm thick aluminum foil of the current collector, and then compacted with a roller press, and then cold pressed, sliced, and welded to obtain the positive electrode sheet.

[0087] (2) Provide negative electrode sheet

[0088] Active material artificial graphite, thickener sodium carboxymethyl cellulose, conductive agent conductive carbon, and binder styrene-butadiene latex are added to solvent deionized water in a mass ratio of 95:1.5:1.5:2 and mixed evenly to make negative electrode slurry. The solid content of ...

Embodiment 2

[0094] (1) Provide positive electrode sheet

[0095] With embodiment 1.

[0096] (2) Provide negative electrode sheet

[0097] With embodiment 1.

[0098] (3) Preparation of composite solid electrolyte membrane

[0099] At 120°C, 1×10 -2 A polymer electrolyte containing polyethylene oxide (PEO, with a weight average molecular weight of 600,000) and LiTFSI (the weight ratio of PEO to LiTFSI is 3:1) was evaporated on the substrate aluminum foil at a high vacuum of 1 μm under Pa as the first step. layer; followed by the inorganic solid electrolyte Li 2 S(75%)-P 2 S 5 (25%) and the above polymer electrolyte at 300°C, 1×10 -3 Pa and 120°C, 1×10 -2 Under Pa, it is vacuum-evaporated on the above-mentioned aluminum foil coated with a polymer electrolyte at a height of 1 μm and 0.01 μm in sequence, wherein, during the alternate deposition process, the number of layers of the inorganic solid electrolyte layer 31 is 1 more than the number of layers of the structural support layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com