Production technology for edible-fungus collagen can

A production process and canning technology, which is applied in the production process field of edible mushroom collagen cans, can solve the problems of difficult absorption of nutrients and low nutritional components, and achieve the effect of low nutritional components, high nutritional value and high retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

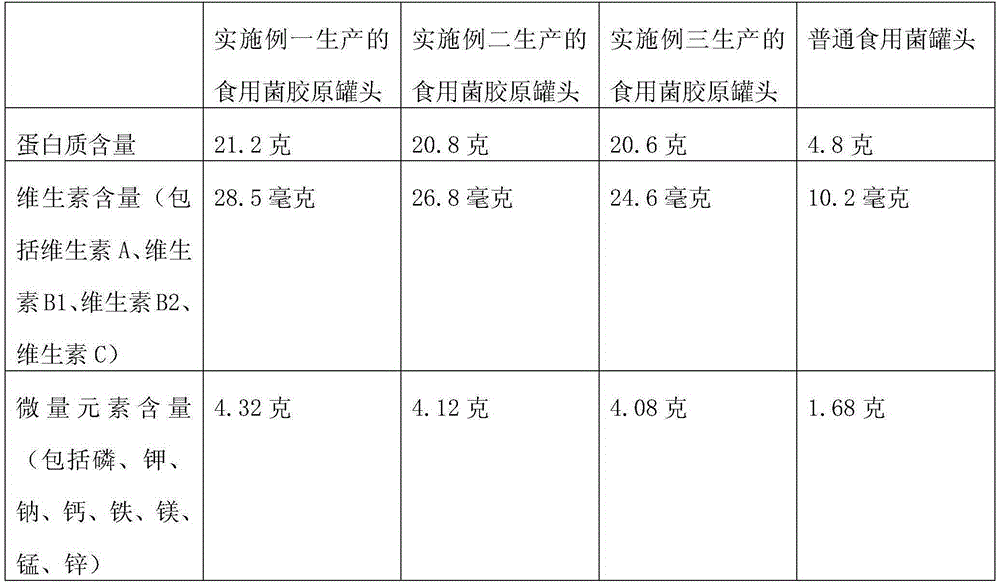

Examples

Embodiment 1

[0018] The production technology of this edible mushroom collagen can comprises the following steps:

[0019] The first step is raw material selection, select high-quality black fungus as raw material;

[0020] The second step is the pre-treatment. The selected raw materials are cleaned of impurities and scales. After cleaning, the raw materials are soaked in clean water for 6 hours;

[0021] The third step is to boil, take out the raw materials after soaking, and then add drinking water, sugar, and taste accessories to the raw materials, wherein the mass ratio of raw materials to drinking water is 1:9, and the mass ratio of raw materials to sugar is 15:1 , the mass ratio of raw material and taste auxiliary material is 10:1, boils after adding drinking water, keeps boiling state after boiling, and keeping time is 5 minutes, obtains grinding raw material after boiling;

[0022] The fourth step is colloid preparation. Put the obtained grinding raw materials into the colloid mil...

Embodiment 2

[0028] The production technology of this edible mushroom collagen can comprises the following steps:

[0029] The first step is raw material selection, and selects excellent white fungus dry product as raw material;

[0030] The second step is the pre-treatment. The selected raw materials are cleaned of impurities and scales. After cleaning, the raw materials are placed in clean water for soaking. The soaking time is 8 hours;

[0031] The third step is to boil, take out the raw materials after soaking, and then add drinking water, sugar, and taste accessories to the raw materials, wherein the mass ratio of raw materials to drinking water is 1:9, and the mass ratio of raw materials to sugar is 15:1 , the mass ratio of raw material and taste auxiliary material is 10:1, boils after adding drinking water, keeps boiling state after boiling, and keeping time is 6 minutes, obtains grinding raw material after boiling;

[0032] The fourth step is colloid preparation. Put the obtained ...

Embodiment 3

[0038] The production technology of this edible mushroom collagen can comprises the following steps:

[0039] The first step is raw material selection, select high-quality black fungus as raw material;

[0040] The second step is the pre-treatment. The selected raw materials are cleaned of impurities and scales. After cleaning, the raw materials are placed in clean water for soaking. The soaking time is 12 hours;

[0041] The third step is to boil, take out the raw materials after soaking, and then add drinking water, sugar, and taste accessories to the raw materials, wherein the mass ratio of raw materials to drinking water is 1:9, and the mass ratio of raw materials to sugar is 15:1 , the mass ratio of raw material and taste auxiliary material is 10:1, boils after adding drinking water, keeps boiling state after boiling, and keeping time is 7 minutes, obtains grinding raw material after boiling;

[0042] The fourth step is colloid preparation. Put the obtained grinding raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com