Tooth desensitizer and preparation and application methods thereof

A technology of desensitization agent and tooth, which is applied in the field of pharmaceutical preparation, can solve the problem of slow onset of action and achieve the effect of alleviating allergic symptoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

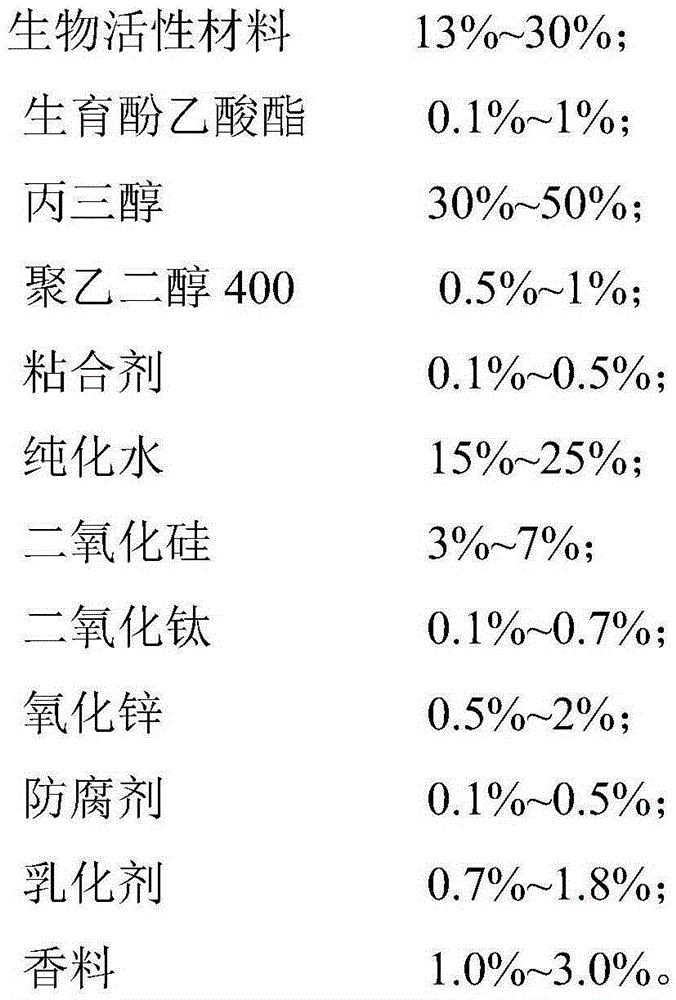

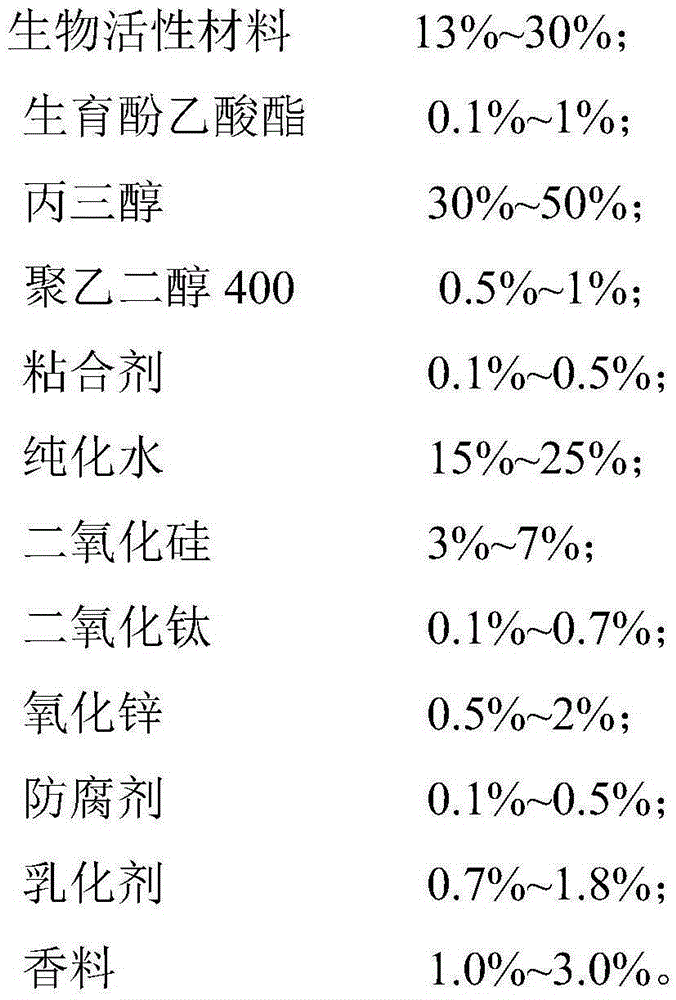

[0029] The tooth desensitizing agent of the present invention comprises the following components by mass: 18% of nanoscale hydroxyapatite, 6% of nanoscale calcium hydrogen phosphate, 0.5% of tocopheryl acetate, 42% of glycerol, polyethylene glycol Glycol 4000.8%, Gum Tragacanth 0.2%, Purified Water 24%, Silicon Dioxide 4%, Titanium Dioxide 0.5%, Zinc Oxide 1%, Methylparaben 0.3%, Sodium Lauryl Sulfate 0.7%, Menthol 1%, Natural Eucalyptus Flavor 1%.

[0030] When preparing tooth desensitizers:

[0031] First, weigh ethyl tocopherol, polyethylene glycol 400, glycerin, natural eucalyptus spice, and purified water in proportion, stir and mix evenly, and use it as material A for later use;

[0032] Then, weigh nano-scale hydroxyapatite, nano-calcium hydrogen phosphate, gum tragacanth, silicon dioxide, titanium dioxide, zinc oxide, methyl hydroxybenzoate, sodium lauryl sulfate, menthol in proportion, stir and mix Uniform, as material B for later use;

[0033] Finally, the prepare...

Embodiment 2

[0036] The tooth desensitizing agent of the present invention comprises the following components by mass: 12% of nanoscale hydroxyapatite, 9% of nanoscale calcium hydrogen phosphate, 1% of tocopherol acetate, 45% of glycerol, polyethylene glycol Glycol 4000.7%, Gum Tragacanth 0.3%, Purified Water 22%, Silica 6, Titanium Dioxide 0.1%, Zinc Oxide 0.9%, Methylparaben 0.2%, Sodium Lauryl Sulfate 0.8%, Menthol 0.5 %, Natural Eucalyptus Flavor 1.5%.

[0037] When preparing tooth desensitizers:

[0038] First, weigh ethyl tocopherol, polyethylene glycol 400, glycerin, natural eucalyptus spice, and purified water in proportion, stir and mix evenly, and use it as material A for later use;

[0039] Then, weigh nano-scale hydroxyapatite, nano-calcium hydrogen phosphate, gum tragacanth, silicon dioxide, titanium dioxide, zinc oxide, methyl hydroxybenzoate, sodium lauryl sulfate, menthol in proportion, stir and mix Uniform, as material B for later use;

[0040] Finally, the prepared mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com