A kind of bionic porous tissue engineering cartilage scaffold preparation method

A porous tissue and engineering technology, applied in the field of biomedicine, can solve problems such as compound ratio transformation, and achieve the effect of improving cartilage quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

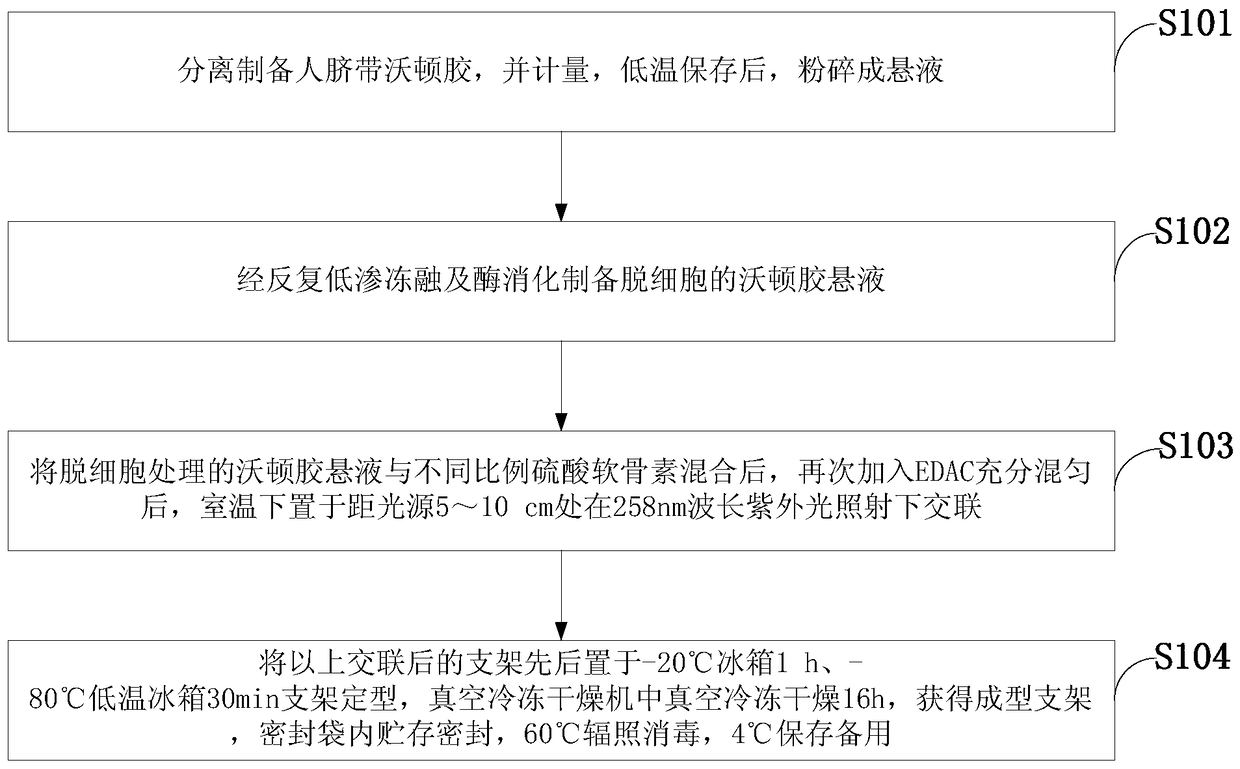

[0024] Such as figure 1 As shown, a kind of biomimetic porous tissue engineering cartilage scaffold preparation method of the embodiment of the present invention comprises the following steps:

[0025] S101: separate and prepare human umbilical cord Wharton's jelly, measure it, store it at low temperature, and crush it into a suspension;

[0026] S102: Prepare decellularized Wharton's gum suspension through repeated hypotonic freezing-thawing and enzymatic digestion;

[0027] S103: Mix the decellularized Wharton gum suspension with chondroitin sulfate in different proportions, add EDAC again and mix thoroughly, place at room temperature at a distance of 5-10 cm from the light source, and cross-link under the irradiation of 258nm wavelength ultraviolet light;

[0028] S104: Place the above cross-linked scaffolds in a -20°C refrigerator and a -80°C low-temperature refrigerator successively to shape the scaffolds, vacuum freeze-dry them in a vacuum freeze dryer to obtain shaped...

Embodiment 1

[0031] Step 1, separate and prepare human umbilical cord Wharton gum, measure it, store it at low temperature, and crush it into a suspension;

[0032] Step 2, preparing decellularized Wharton gum suspension through repeated hypotonic freeze-thaw and enzyme digestion;

[0033] Step 3: Mix the decellularized Wharton’s gum suspension with chondroitin sulfate, Wharton’s gum suspension: chondroitin sulfate = 2:0.25, add EDAC again and mix well, place at room temperature 5-10cm away from the light source Cross-linking under 258nm wavelength ultraviolet light irradiation;

[0034] Step 4: Place the above cross-linked scaffolds in a -20°C refrigerator and a -80°C low-temperature refrigerator to shape the scaffolds, freeze and dry them in a vacuum freeze dryer to obtain shaped scaffolds, store them in sealed bags, and irradiate at 60°C Sterilize and store at 4°C for later use.

Embodiment 2

[0036] Step 1, separate and prepare human umbilical cord Wharton gum, measure it, store it at low temperature, and crush it into a suspension;

[0037]Step 2, preparing decellularized Wharton gum suspension through repeated hypotonic freeze-thaw and enzyme digestion;

[0038] Step 3, mix the decellularized Wharton’s gum suspension with different proportions of chondroitin sulfate, the mass ratio of Wharton’s gum suspension to chondroitin sulfate is 2.0:0.75; add EDAC again and mix well, place at room temperature Cross-linking under the irradiation of 258nm wavelength ultraviolet light at a distance of 5-10cm from the light source;

[0039] Step 4: Place the above cross-linked scaffolds in a -20°C refrigerator and a -80°C low-temperature refrigerator successively to shape the scaffolds, vacuum freeze-dry them in a vacuum freeze dryer to obtain shaped scaffolds, store and seal them in sealed bags, and irradiate at 60°C Sterilize and store at 4°C for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com