A kind of treatment method of coke oven flue gas treatment system

A flue gas treatment system and treatment method technology, applied in the direction of separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of ammonia leakage investment costs and operating costs, catalysts are easily poisoned, and the process is uneconomical. Secondary pollution problem, low operating cost, low operating cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

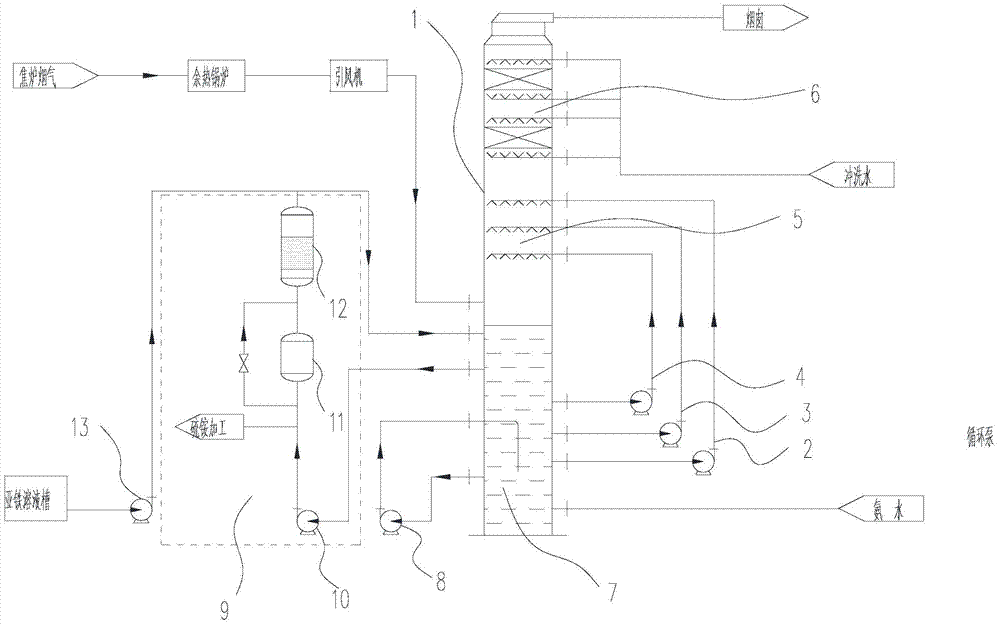

[0039] The coke oven flue gas treatment system of the present invention, such as figure 1 As shown, including coke oven flue gas inlet, absorption tower 1, clean flue gas outlet (ie figure 1 middle chimney), the coke oven flue gas inlet is arranged in the middle of the absorption tower 1, the clean flue gas outlet is arranged at the top of the absorption tower 1, and in the absorption tower 1 is also provided with:

[0040] The absorption and spraying section 5 at the upper part of the coke oven flue gas inlet,

[0041] The water washing and defogging section 6 located at the upper part of the absorption spraying section 5 and the lower part of the clean flue gas outlet,

[0042] A slurry tank 7 for absorbing liquid at the lower part of the coke oven flue gas inlet;

[0043] Said slurry tank 7 is provided with an absorption spray circuit (i.e. comprising absorption liquid circulation pump one 2, absorption liquid circulation pump two 3, three branch circulation circuits of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com