Magnetic biochar composite material preparation method based on microalgae

A composite material, bio-carbon technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of unfriendly processes, discontinuous magnetic bio-carbon materials, and long production cycles , to achieve the effect of large application value, easy magnetic separation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

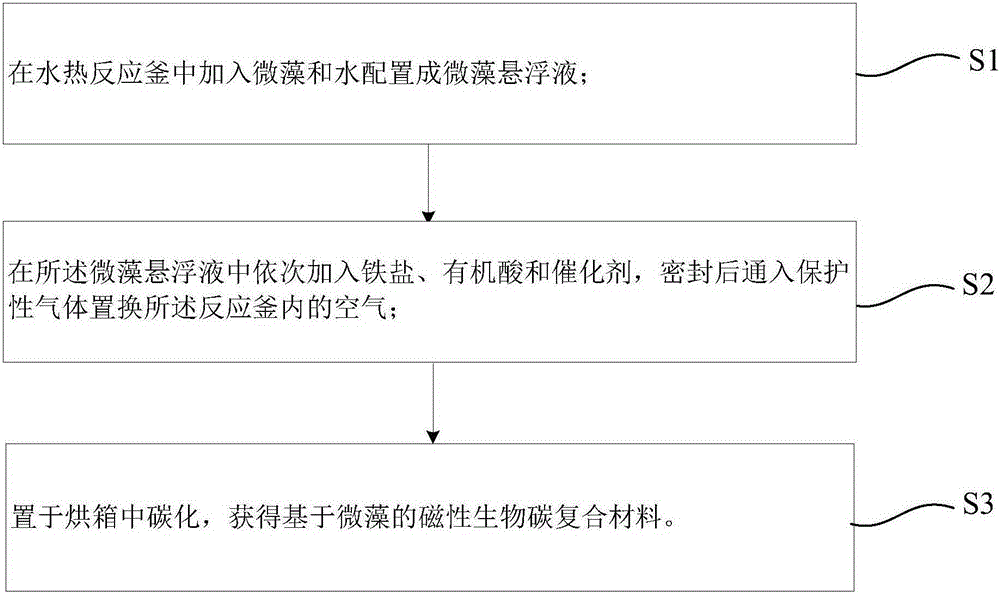

[0027] The invention provides a method for preparing a microalgae-based magnetic bio-carbon composite material, such as figure 1 As shown, the preparation method at least includes the following steps:

[0028] S1, adding microalgae and water into a hydrothermal reactor to prepare a microalgae suspension;

[0029] S2, sequentially adding iron salt, organic acid and catalyst to the microalgae suspension, sealing and introducing a protective gas to replace the air in the reactor;

[0030] S3, placed in an oven for carbonization to obtain a microalgae-based magnetic bio-carbon composite material.

Embodiment 1

[0033] Accurately weigh 1.0g of freeze-dried green algae, 50ml of deionized water, add it to a 100ml hydrothermal reaction kettle, and add 3g of FeCl in sequence 3 , 3g of sodium acetate catalyst, 1g of oxalic acid, ultrasonic 10min after each substance is added, the reaction kettle is sealed and passed into N 2 The air in the kettle was replaced, and finally placed in an oven at 180°C for carbonization for 24 hours, cooled, filtered, washed, dried, and then vacuum-dried at 80°C for 12 hours to obtain a magnetic bio-carbon composite material.

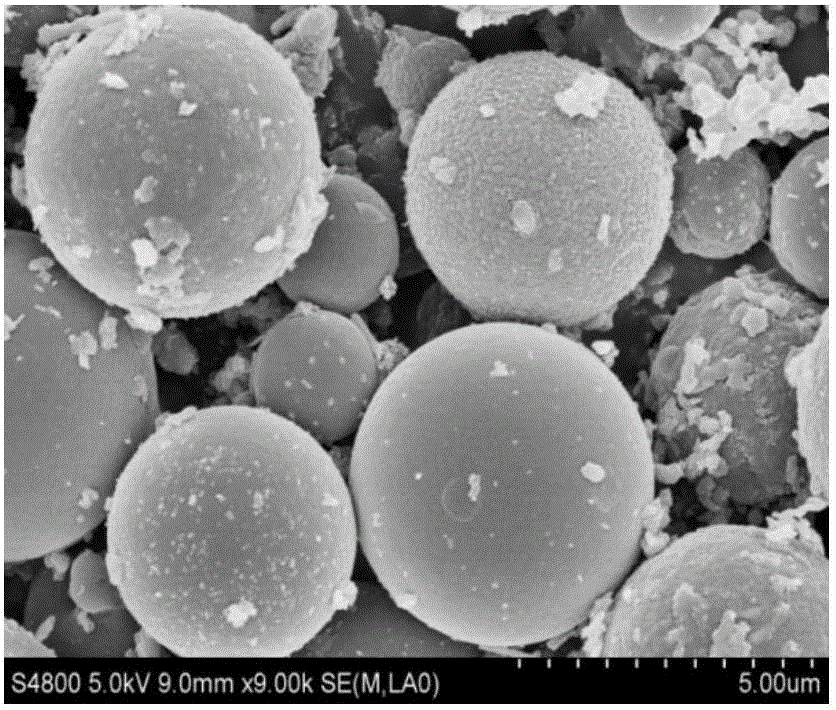

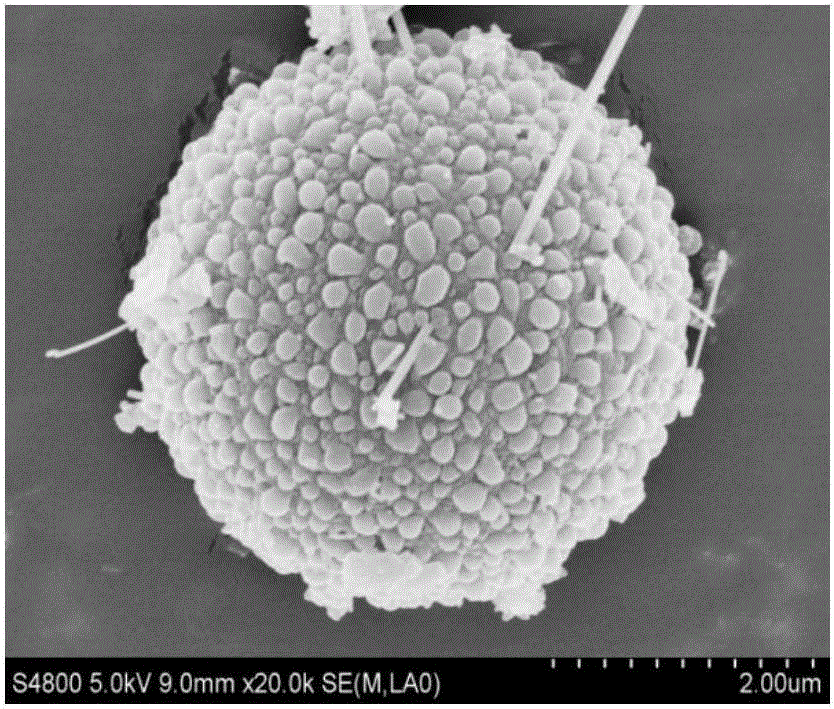

[0034] Such as figure 2 Shown is the scanning electron microscope (SEM) image of the prepared magnetic bio-carbon composite. image 3 An enlarged view of the magnetic biocarbon composite. From figure 2 and image 3 It can be seen that the synthesized magnetic material is composed of a large number of microsphere particles, the size is micron, the surface is rough, and it is covered by a layer of white crystal-like particles. This ...

Embodiment 2

[0036] Accurately weigh 2.0g of Scenedesmus after freeze-drying treatment, 50ml of deionized water, add it to a 100ml hydrothermal reaction kettle, and add 1g of FeCl in sequence 3 , 2g of sodium acetate catalyst, 1g of acrylic acid, ultrasonic 10min after each substance is added, the reactor is sealed and then passed into N 2 The air in the kettle was replaced, and finally placed in an oven at 180°C for carbonization for 24 hours, cooled, filtered, washed, dried, and then vacuum-dried at 80°C for 12 hours to obtain a magnetic bio-carbon composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com