Method and system for preparing salt from seawater

A technology of seawater and water inflow, which is applied in the field of salt production, can solve the problems of not meeting the high requirements of ion membrane caustic soda salt, complicated process, high treatment cost, etc., and achieve high economic and social benefits, reduced evaporation area, and high salt production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

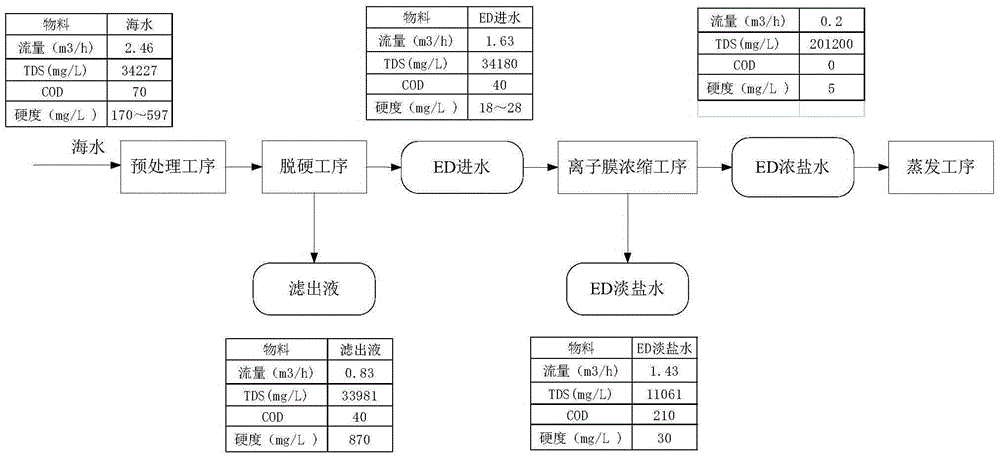

[0054] see figure 1 , the system of seawater salt production of the present embodiment comprises:

[0055] The grit chamber, the grit chamber is set on the tidal flat, and the water is taken through the grit chamber, and the seawater is naturally infiltrated by the grit chamber, and then sent to the mechanical filter pool through the pumping station;

[0056] For the mechanical filter tank, the chemical dosing point is designed at the seawater inlet of the mechanical filter tank, and the seawater is sterilized, flocculated and filtered by metering an appropriate amount of fungicides, flocculants and other chemicals, so that the effluent of the mechanical filter tank meets SS≦1 , free chlorine≦1.5;

[0057] Nanofiltration membrane filter; the inlet water of nanofiltration membrane filter is the seawater that is processed through mechanical filter pool, (in the present embodiment, the inlet water volume of nanofiltration membrane filter is 2.46m 3 / h, after treatment with nano...

Embodiment 2

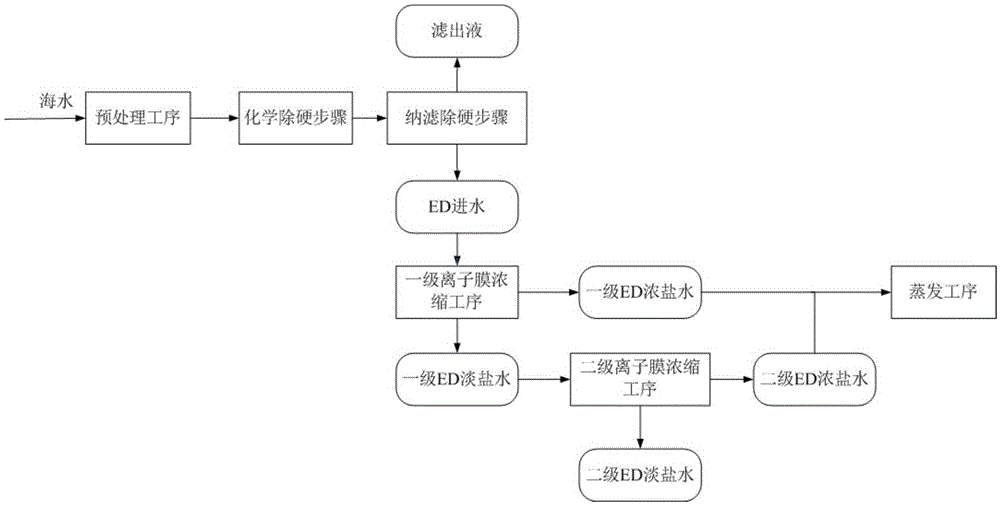

[0069] Other equipment in this embodiment is the same as in Embodiment 1, except that the ionic membrane reactor in this embodiment includes a primary ionic membrane reactor and a secondary ionic membrane reactor. The first-level ED concentrated brine from the first-level ionic membrane reactor enters the second-level ionic membrane reactor for further processing to obtain the second-level ED light brine and the second-level ED concentrated brine. The secondary ED concentrated brine enters the evaporation crystallizer. The first grade ED salt water and the second grade ED salt water are mixed to obtain ED salt water, which can be used as the influent water of the reverse osmosis process or supplementary water for industrial production circulating water, as well as water for irrigation of salt-tolerant plants in coastal areas.

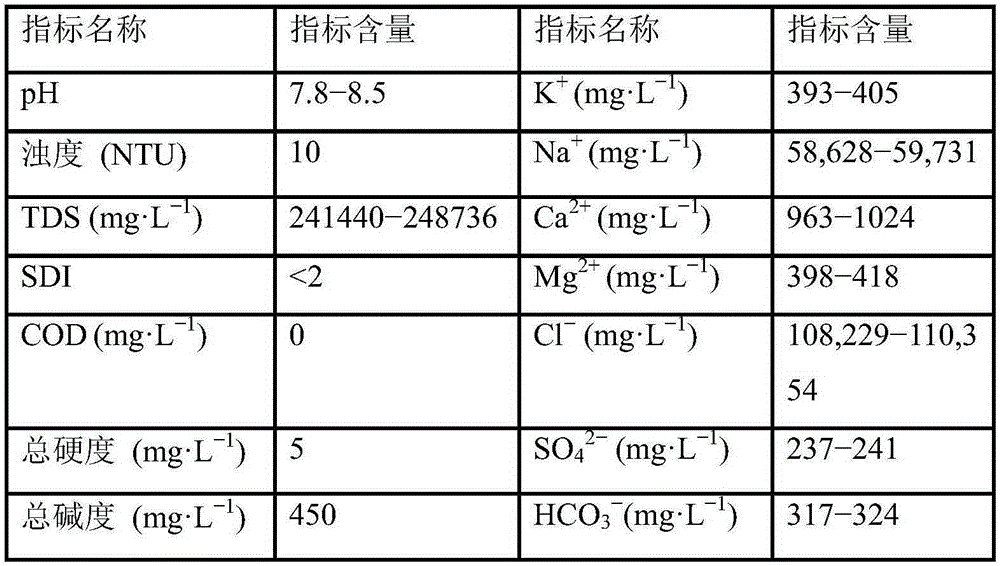

[0070] The water quality parameters of the secondary ED concentrated brine obtained in Example 2 are shown in Table 3.

[0071] The water quality para...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dc power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com