Permeable reactive barrier filler

A technology of active percolation wall and filler, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of single function and high cost of filling medium, and achieve low cost, cheap price and abundant resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

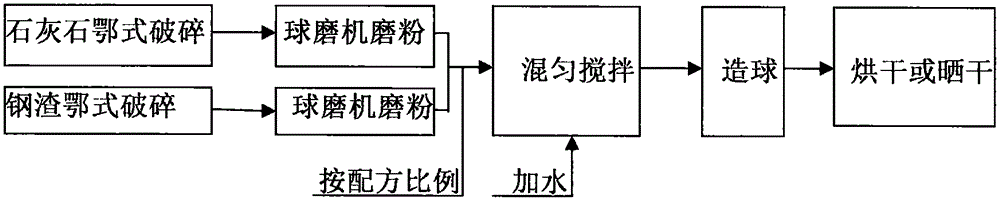

[0023] The preparation process of the active percolation wall filler described in the present embodiment is as follows: figure 1 As shown, limestone and steel slag are crushed into granules with a particle size of less than 15cm by a jaw crusher, and then sent to a ball mill for grinding, and ground into a powder with a particle size of 150 to 200 meshes. As an example, in this embodiment The steel slag is converter slag from a steel plant, which contains: 20wt% FeO, 38wt% CaO, 12wt% SiO 2 , 10wt% MgO, 5wt% MnO, 3wt% Al 2 o 3 , and 1.2wt% P 2 o 5 , and other components of the balance. Then mix the prepared limestone powder and steel slag powder in a steel container at a mass ratio of 6:4, add water and stir evenly to obtain a mixture, and the amount of water added is 10-15 wt% of the filler. The mixture is sent to the pelletizing machine for pelletizing, and the ball diameter is controlled to be 5-20mm. Finally, the prepared filler with a ball diameter of 5-20 mm is drie...

Embodiment 2

[0025] Use a jaw crusher to crush limestone and steel slag into granules with a particle size of less than 15 cm, and then send them to a ball mill for grinding, and grind them into powders with a particle size of 150 to 200 meshes. As an example, the steel slag in this embodiment is Converter slag from a steel plant, which contains: 20wt% FeO, 38wt% CaO, 12wt% SiO 2 , 10wt% MgO, 5wt% MnO, 3wt% Al 2 o 3 , and 1.2wt% P 2 o 5 , and other components of the balance. In this embodiment, the milled steel slag is subjected to steam calcination treatment in a circulating fluidized bed, and the flow ratio of steam and air is controlled to be 2:8 under normal pressure conditions, and the calcination treatment is controlled under turbulent flow. The temperature is 800-900°C, and the treatment time is 60 minutes. Then mix the prepared limestone powder and steel slag powder in a steel container at a mass ratio of 6:4, add water and stir evenly to obtain a mixture, and the amount of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com