Cement grinding aid

A technology of cement grinding aid and sodium sulfate, which is applied in the field of cement and can solve the problems of long concrete setting time and low concrete strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

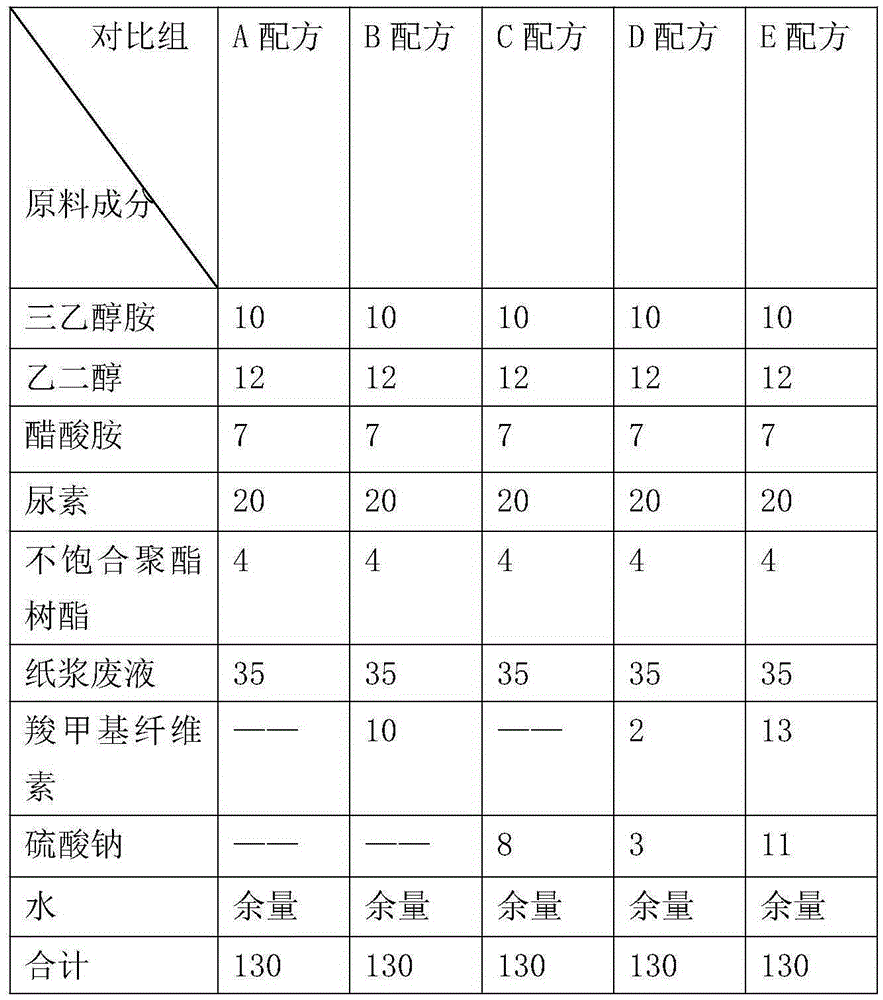

[0007] Cement grinding aids are configured according to the components and parts by mass in Table 1, Table 2, and Table 3 below.

[0008]

[0009] Table 1

[0010]

[0011]

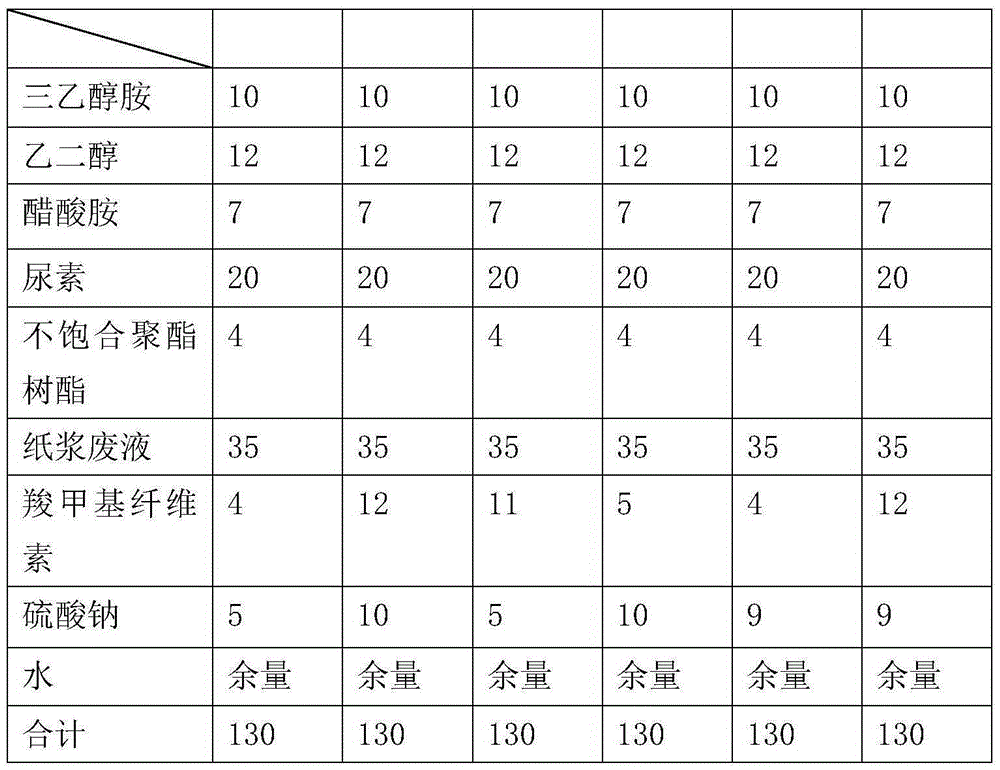

[0012] Table 2

[0013]

[0014] table 3

[0015] In the above tables, the processing steps are:

[0016] Step 1: At a temperature of 30 degrees Celsius, filter out impurities from the quality pulp waste liquid, add triethanolamine to homogenize (stir well) for 15 minutes, then add urea and ammonium acetate, homogenize for 15 minutes, and then add unsaturated Synthetic polyester resin, the unsaturated polyester resin in this scheme adopts isophthalic unsaturated polyester resin, homogenized for 20 minutes.

[0017] The second step: After mixing and stirring the carboxymethyl cellulose and the sodium sulfate passing the 180 mesh evenly, the mixture is mixed into the components of the first step and stirred evenly again, and the stirring time is 10 minutes . Then store and stop for 24 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com