Flexible polymer conductor, and preparation method and applications thereof

A flexible polymer and conductor technology, applied in the direction of additive processing, etc., can solve the problems of difficult to achieve large-area production and complex preparation technology of flexible conductors, and achieve excellent flexibility, excellent electrical conductivity, and excellent electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

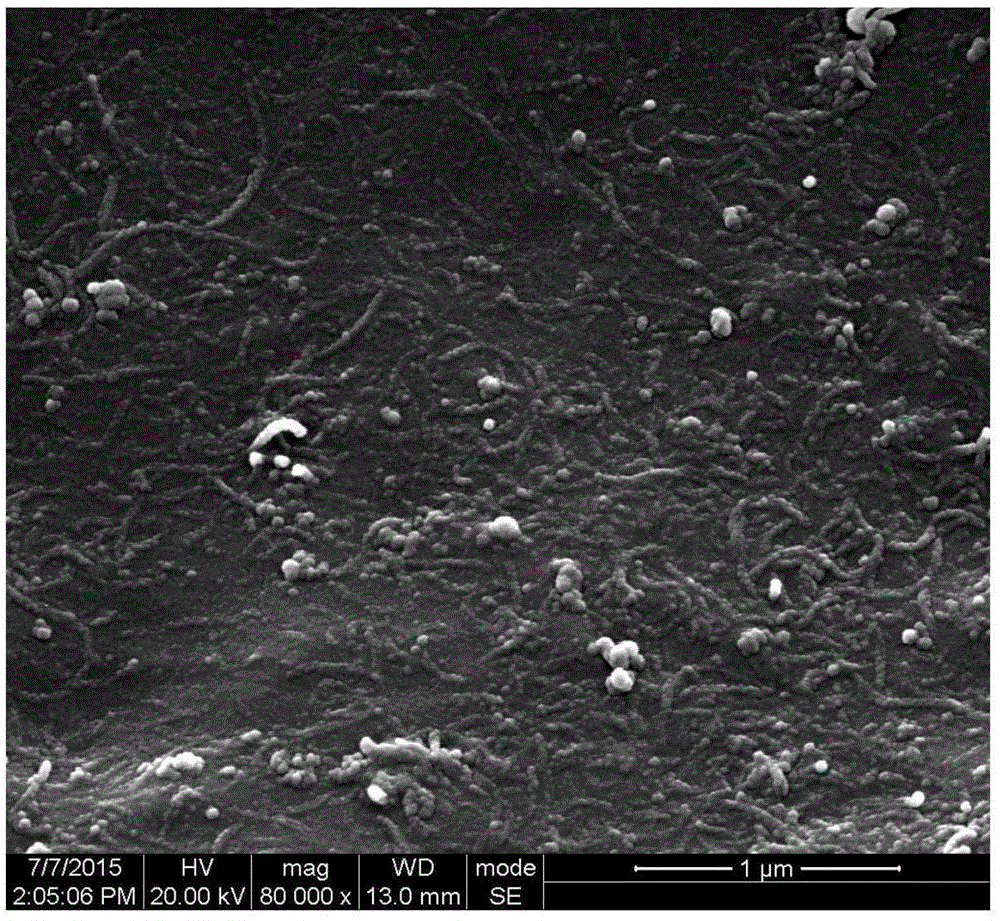

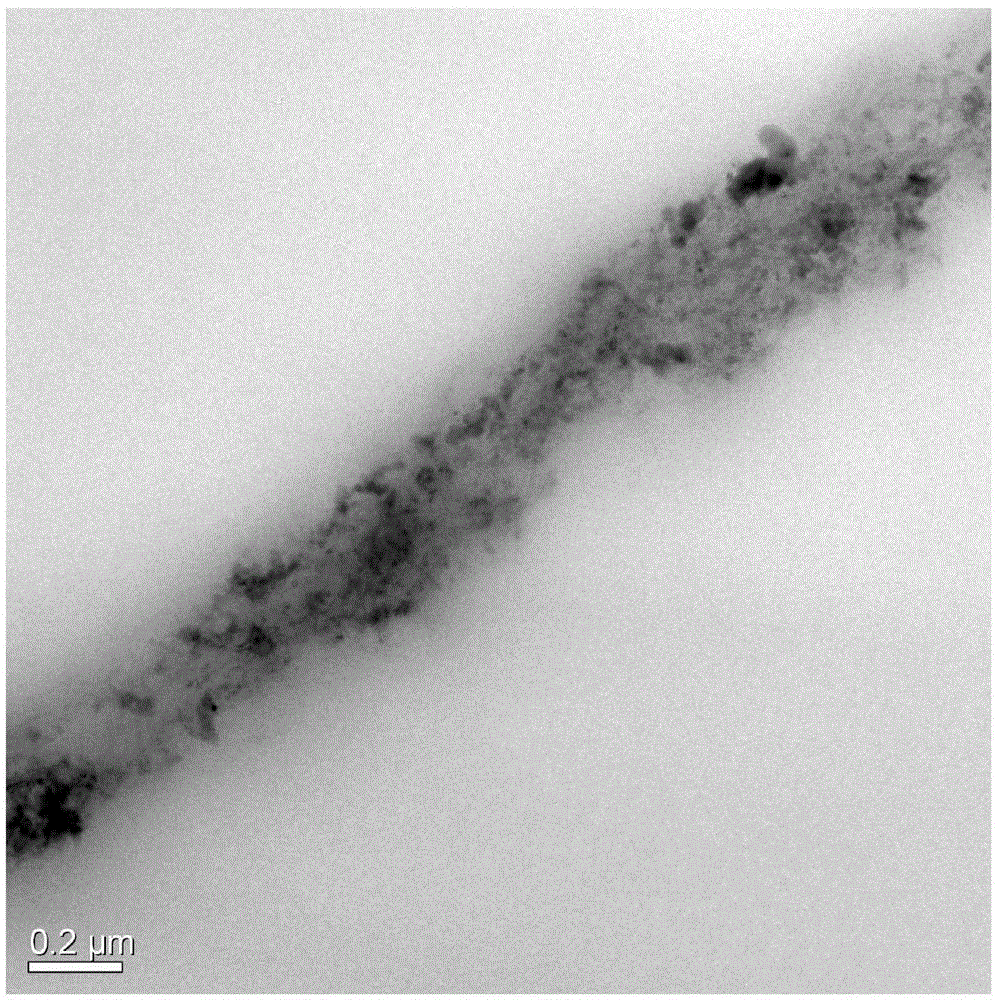

[0043] Dissolving 0.1 part of stearic acid in excess water, then adding 0.01 part of single-walled carbon nanotubes, and ultrasonically dispersing under stirring conditions, to obtain a dispersion liquid dispersed with nano conductive materials;

[0044]Add 100 parts of polyurethane thermoplastic elastomer powder to the above-mentioned dispersion liquid with single-walled carbon nanotubes, and stir rapidly so that the single-walled carbon nanotubes can be fully and uniformly coated on the surface of polyurethane thermoplastic elastomer particles; finally mix The solution is suction filtered, and the obtained powder is dried and screened to obtain polyurethane thermoplastic elastomer powder coated with single-walled carbon nanotubes;

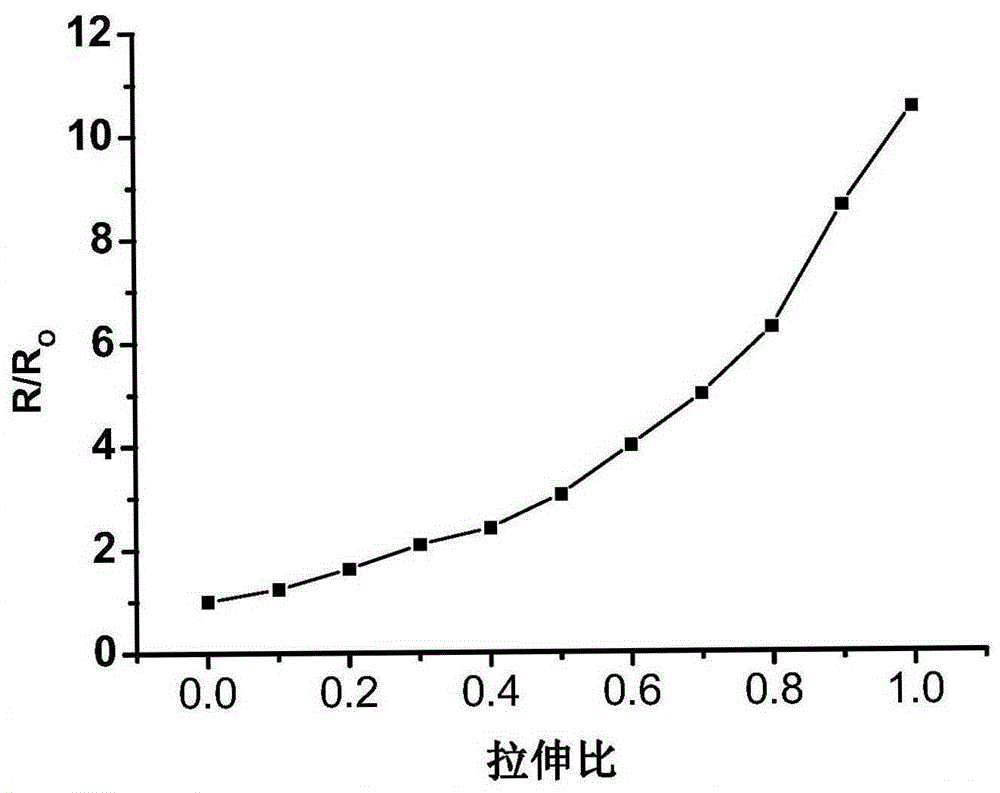

[0045] Spread the polyurethane thermoplastic elastomer powder coated with single-walled carbon nanotubes on the workbench of the selective laser sintering equipment, set the temperature at 70°C, the thickness of the single layer is 0.05mm, the las...

Embodiment 2

[0048] Dissolving 0.2 parts of sodium lauryl alcohol polyoxyethylene ether sulfate in excess water, then adding 2 parts of single-walled carbon nanotubes, and ultrasonically dispersing under stirring conditions to obtain a dispersion liquid dispersed with nano conductive materials;

[0049] Add 100 parts of polyurethane thermoplastic elastomer powder to the above-mentioned dispersion liquid with single-walled carbon nanotubes, and stir rapidly so that the single-walled carbon nanotubes can be fully and uniformly coated on the surface of polyurethane thermoplastic elastomer particles; finally mix The solution is suction filtered, and the obtained powder is dried and screened to obtain polyurethane thermoplastic elastomer powder coated with single-walled carbon nanotubes;

[0050] Spread the polyurethane thermoplastic elastomer powder coated with single-walled carbon nanotubes on the workbench of the selective laser sintering equipment, set the temperature at 70°C, the thickness ...

Embodiment 3

[0053] Dissolving 0.3 parts of ammonium lauryl sulfate in excess water, then adding 4 parts of single-walled carbon nanotubes, and ultrasonically dispersing under stirring conditions to obtain a dispersion liquid dispersed with nano-conductive materials;

[0054] Add 100 parts of polyurethane thermoplastic elastomer powder to the above-mentioned dispersion liquid with single-walled carbon nanotubes, and stir rapidly so that the single-walled carbon nanotubes can be fully and uniformly coated on the surface of polyurethane thermoplastic elastomer particles; finally mix The solution is suction filtered, and the obtained powder is dried and screened to obtain polyurethane thermoplastic elastomer powder coated with single-walled carbon nanotubes;

[0055] Spread the polyurethane thermoplastic elastomer powder coated with single-walled carbon nanotubes on the workbench of the selective laser sintering equipment, set the temperature at 70°C, the thickness of the single layer is 0.05m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com