Novel beer preparation process

A preparation process and technology of beer, applied in the field of brewing, can solve the problems of high cost of beer, increased production and transportation costs, and rising prices of raw materials for production, and achieve the effects of reducing energy consumption costs, reducing production costs, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

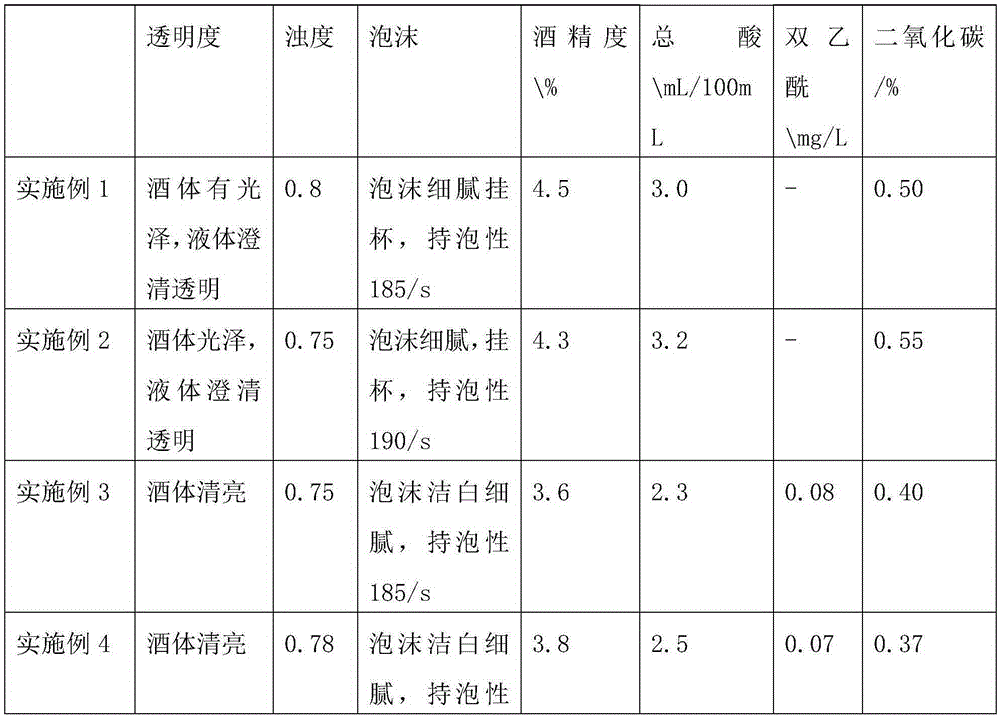

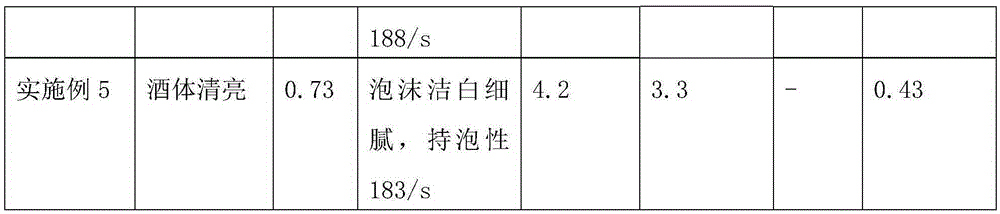

Examples

Embodiment 1

[0054] The new beer raw material of this embodiment consists of 10 parts by weight of soybean peptide, 20 parts of maltose, 10 parts of glucose, 20 parts of dextrin, and 20 parts of fructooligosaccharide.

[0055] Take a certain amount of above-mentioned beer powder raw material, add 8kgRO (reverse reference water, the same below) water, be mixed with the liquid mixture that sugar content is 14~15 ° of Bé. The resulting liquid mixture is boiled under normal pressure, and hops are added in an amount of 200g / 100L (relative to the liquid mixture) at the beginning of boiling for 5 to 10 minutes, boiled for 100 minutes, the boiling intensity is controlled at 9% / h, and the pH value of the liquid is controlled at about 5.2 . Filter out the hot coagulation produced in the liquid mixture, quickly cool the wort to 9°C, pour it into a fermenter, add brewer's yeast for beer fermentation, and control the fermentation degree at 60% to 75%. Add 0.3kg / m 3 The active dry yeast relative to th...

Embodiment 2

[0056] The new beer raw material of the present embodiment consists of 5 parts by weight of soybean peptide, 40 parts of maltose, 20 parts of lactose, 20 parts of sucrose, and 20 parts of xylooligosaccharide.

[0057] Weigh 1kg of the above-mentioned beer powder raw material, add 8kg of RO water, and prepare a liquid mixture with a sugar content of 14-15°Bé. The resulting liquid is boiled under normal pressure, and hops are added by "secondary addition method". 10-20 minutes after the start of boiling, add 70-80% of the total amount of hops (relative to the liquid mixture); for the second time, 30 minutes before the end of boiling, add the remaining hops, and the total amount of hops added is 120-180g of the wort amount / L is added, the boiling intensity is controlled at 8% / h, and the pH value of the liquid is controlled at about 5.2. Filter out the hot coagulation produced during the boiling of the liquid mixture, quickly cool the wort to 9°C, pour it into a fermenter, add brew...

Embodiment 3

[0059] The new beer raw material of this embodiment consists of 8 parts by weight of soybean peptide, 50 parts of white granulated sugar, 10 parts of fructose and 20 parts of starch. Under the GMP condition, each component is mixed uniformly to obtain a solid new beer raw material.

[0060] Weigh 1kg of the above-mentioned beer powder raw material, add 10kg of RO water, and prepare a liquid mixture with a sugar content of 11-12°Bé. The resulting liquid is boiled under normal pressure, and hops are added using the "three-time addition method". The total amount of hops added is 160-240g / L. For the first time, add 20-30% of the total amount after the initial boiling for 5-10 minutes. For the second time, add 50-60% of the total amount after boiling for about 40 minutes. , the third time, 5-10 minutes before the end of boiling, add the remaining amount of hops. The boiling intensity is controlled at 10% / h, and the pH value of the liquid is controlled at around 5.2. Filter out th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com