Plutonium content analysis method

An analysis method and content technology, applied in the field of radiochemistry, can solve the problems of time-consuming source preparation, unfavorable for timely acquisition of plutonium content data in a post-processing plant, and difficulty in reaching the lower detection limit of an α measuring instrument due to low Pu concentration ratio, and achieves simple operation. , The effect of short measurement time and shortened analysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

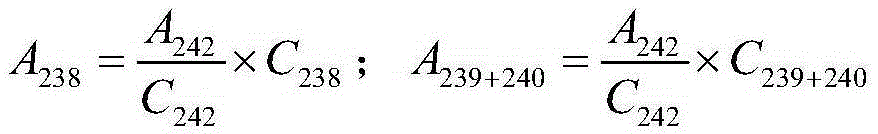

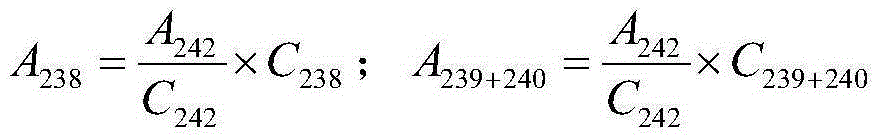

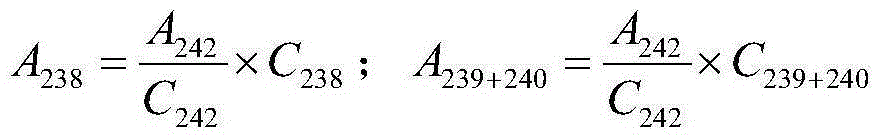

[0041] A method for analyzing plutonium content provided by the application, the method comprises the following steps:

[0042] (1) Sampling and addition of isotope diluent

[0043] Weigh the post-treatment PUREX process 1CU material liquid as the sample solution to be analyzed 0.1mL, add 242 Pu tracer, 242 The amount of Pu tracer in the sample solution 239 The content of Pu is close to that.

[0044] (2) Valence regulation of Pu

[0045] Add the ferrous sulfamate solution of 7mol / L nitric acid solution and 0.5mol / L in above-mentioned sample solution to be analyzed, make the nitric acid acidity be 0.5mol / L in the sample solution to be analyzed, ferrous sulfamate concentration is 0.1mol / L L, and kept for 40min, the ferrous sulfamic acid solution reduced the valence state of Pu to Pu(Ⅲ); then added 0.8mol / L sodium nitrite solution to the sample solution to be analyzed, kept for 40min, and Pu(Ⅲ) Oxidation to Pu(Ⅳ);

[0046] (3) TTA-xylene solution extraction

[0047] Extra...

Embodiment 2

[0065] Different from Example 1, the volume of the sample solution to be analyzed is 0.3mL in the step (1); the concentration of the nitric acid solution added in the step (2) is 8mol / L, and the acidity of nitric acid in the sample solution to be adjusted is 1mol / L L, ferrous sulfamic acid concentration is 0.2mol / L, and the concentration of sodium nitrite solution is 0.9mol / L; In step (3), the concentration of TTA-xylene solution is 0.5mol / L, TTA-xylene solution and The volume ratio of Pu (Ⅳ) solution is 2:1; In step (4), the concentration of washing nitric acid is 1mol / L, and the concentration of stripping nitric acid is 8mol / L; Among the step (5), nitric acid concentration is 8mol / L, Each 25mL of pretreatment reagent, flow velocity is 20mL / min; The volume of stripping aqueous phase solution taken in step (6) is 12mL, and flow velocity is 18mL / min, and the concentration of washing nitric acid is 8mol / L, and flow velocity is 18mL / min; In step (8), the low-background α-energy s...

Embodiment 3

[0067] Different from Example 1, the volume of the sample solution to be analyzed is 0.5mL in the step (1); the concentration of the nitric acid solution added in the step (2) is 9mol / L, and the acidity of nitric acid in the sample solution to be adjusted is 1.5mol / L, the concentration of ferrous sulfamic acid is 0.2mol / L, and the concentration of sodium nitrite solution is 1.0mol / L; In step (3), the concentration of TTA-xylene solution is 0.6mol / L; In step (4) , the concentration of washing nitric acid is 1.5mol / L, and the concentration of stripping nitric acid is 9mol / L; In the step (5), the concentration of nitric acid is 9mol / L; The volume of the stripping aqueous phase solution taken in the step (6) is 15mL, The flow rate is 20mL / min, the concentration of washing nitric acid is 9mol / L, and the flow rate is 20mL / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com