Super capacitor and preparation method thereof

A supercapacitor and electrode technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of environmental pollution, animal diseases, high-cost garbage disposal, etc., and achieve high specific surface area and broad application prospects. , The effect of good cycle charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

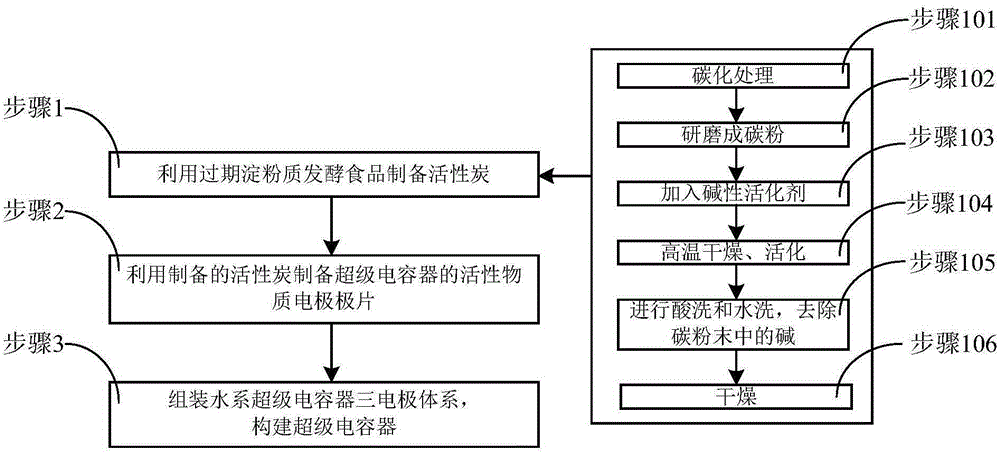

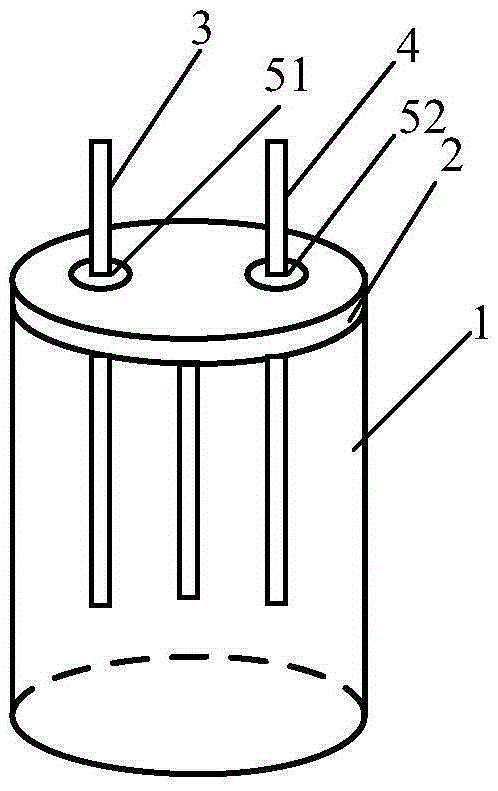

[0053] Example 1, as figure 1 As shown, the method for preparing a supercapacitor according to the first embodiment of the present invention includes:

[0054] Step 1, using expired starchy fermented food to prepare activated carbon, specifically including:

[0055] Step 101, carbonization treatment:

[0056]Place 200 g of expired steamed buns in a tube furnace, set a carbonization temperature of 500 degrees, keep the temperature for 1 hour, and carry out high-temperature carbonization to obtain carbon materials;

[0057] Step 102, grinding into toner powder:

[0058] Grinding the carbonized carbon material into carbon powder;

[0059] Step 103, adding alkaline activator:

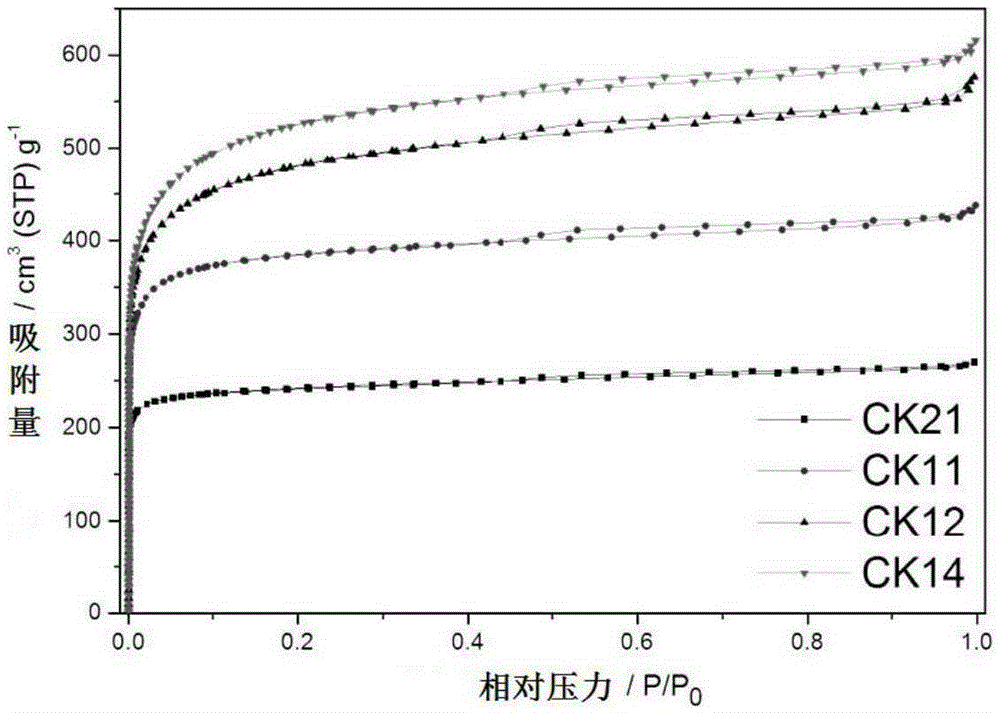

[0060] Mix the alkaline activator KOH and carbon powder uniformly according to the mass ratio of 0.5:1, and add 30ml of distilled water to fully dissolve the alkaline activator KOH and stir evenly, and mark the obtained sample as CK21;

[0061] Step 104, high temperature drying and activation:

[0062...

Embodiment 2

[0072] In Example 2, the preparation method of the supercapacitor is different from that in Example 1 in that the mass ratio of the alkaline activator KOH to the carbon powder in step 103 is 1:1, and the obtained sample is marked as CK11. The structure of the prepared supercapacitor is the same as that of Example 1, the difference is that the electrode material of the material electrode plate 3 is prepared from the sample CK11.

Embodiment 3

[0073] In Example 3, the preparation method of the supercapacitor is different from that in Example 1 in that the mass ratio of the alkaline activator KOH to the carbon powder in step 103 is 2:1, and the obtained sample is marked as CK12. The structure of the prepared supercapacitor is the same as that of Example 1, the difference is that the electrode material of the material electrode plate 3 is prepared from the sample CK12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com