Preparation method of CeO2-Cr2O3-Nb2O5 compound oxide catalyst

The technology of ceo2-cr2o3-nb2o5 and composite oxides is applied in the field of preparation of chlorine-containing organic waste gas combustion catalysts, and can solve the problems of low catalytic activity, deactivation of oxy-chlorine compounds and the like, and achieves low catalyst cost, simple and good preparation process. Effects of catalytic degradation activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

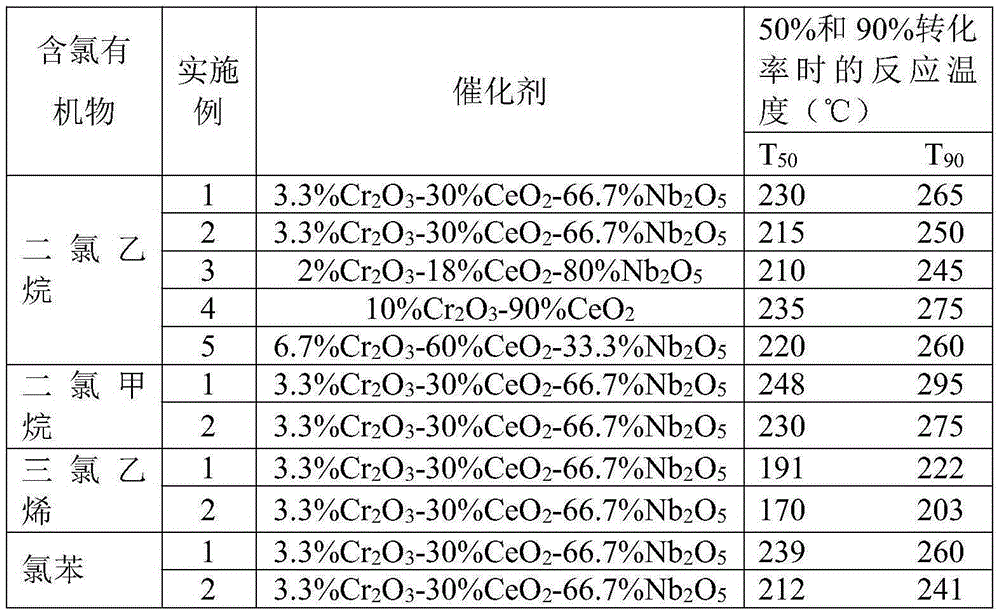

Examples

Embodiment 1

[0015] 3.6gCr(NO 3 ) 3 9H 2 O and 15.6gCe(NO 3 ) 3 ·6H 2 Dissolve O in 180mL water, stir well and add 13.8g Nb 2 o 5 Powder. Add dropwise (NH 4 ) 2 CO 3 Precipitating agent, added dropwise until the pH value of the solution reaches 9.0, then aged at room temperature for 12 hours, then filtered, washed with deionized water and ethanol for several times until the filtrate is neutral, dried at 110°C for 2 hours, and roasted at 500°C for 2 hours. , making CeO 2 -Cr 2 o 3 -Nb 2 o 5 composite oxide catalyst. The mol ratio of Ce / Cr in this catalyst is 4:1, (Cr 2 o 3 +CeO 2 ) / Nb 2 o 5 The mass ratio is 1:2.

Embodiment 2

[0017] With the same operation of embodiment 1, the difference is: with 1.1gCr (NO 3 ) 3 9H 2 O, 4.7gCe(NO 3 ) 3 ·6H 2 O and 15.6g ammonium niobium oxalate were dissolved in 180mL water, stirred evenly and added dropwise under vigorous stirring (NH 4 ) 2 CO 3 Precipitant. The mol ratio of Ce / Cr in this catalyst is 4:1, (Cr 2 o 3 +CeO 2 ) / Nb 2 o 5 The mass ratio is 1:2.

Embodiment 3

[0019] With the same operation of embodiment 1, the difference is: with 0.6gCr (NO 3 ) 3 9H 2 O, 2.8gCe(NO 3 ) 3 ·6H 2 O and 18.4g ammonium niobium oxalate were dissolved in 180mL water, stirred evenly and added dropwise under vigorous stirring (NH 4 ) 2 CO 3 Precipitant. The mol ratio of Ce / Cr in this catalyst is 4:1, (Cr 2 o 3 +CeO 2 ) / Nb 2 o 5 The mass ratio is 1:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com