A Digital Display Control System of a Digital Display Radial Arm Drilling Machine

A technology of radial drilling machine and control system, which is applied in the direction of manufacturing tools, large fixed members, metal processing machinery parts, etc., and can solve problems such as difficult implementation, poor function, and inability to use spindle feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

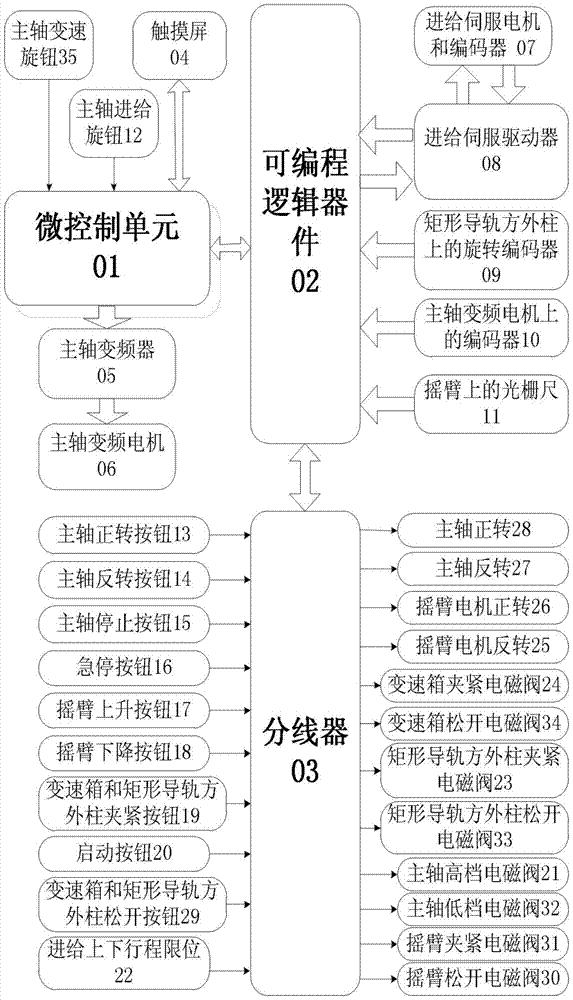

[0016] Referring to the accompanying drawings, a digital display control system of a digital display radial drilling machine includes a micro control unit 01, a programmable logic device 02, and a splitter 03. The micro control unit 01 performs comprehensive analysis and calculation, and sends an analog value to the spindle for frequency conversion The device 05 and the programmable logic device 02 are combined to complete sending pulses and record the number of pulses. The micro-control unit 01 needs to communicate with the programmable logic device 02. The programmable logic device 02 is used as the memory of the micro-control unit 01 to read and write. ; The feedback of the incremental signal processing by programming the programmable logic device 02 includes the feed servo motor fed back by the feed servo driver 08 and the encoder signal of the encoder 07, the signal of the rotary encoder 09 on the square outer column of the rectangular guide rail, The encoder 10 signal on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com