Method and equipment for degrading organic waste water through UV-light concerted electro-Fenton system

An ultraviolet light and system technology, applied in energy wastewater treatment, textile industry wastewater treatment, light water/sewage treatment, etc., can solve the problems of water environmental pollution, high total organic carbon content of wastewater, and difficult biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0105] Preparation of Ultraviolet Light Synergistic Electro-Fenton System

[0106] The ultraviolet light synergistic electro-Fenton system of the present invention is mainly prepared by the following steps:

[0107] (1) preparing the cathode electrode, wherein the cathode electrode contains (a) polytetrafluoroethylene, and (b) graphite and / or carbon nanotubes;

[0108] (2) The cathode electrode prepared in step (1), the inert anode and the electrolyte solution are combined into a Fenton system, and a certain voltage and ultraviolet light irradiation are applied simultaneously.

[0109] In another preferred example, the method includes the following step (3): adding the waste liquid containing pollutants to be treated to the ultraviolet light synergistic electro-Fenton system, electrifying at a certain voltage for a period of time, and The pollutants mentioned above are degraded.

[0110] In another preferred example, in the step (1), it includes: mixing the following cathode...

Embodiment 1

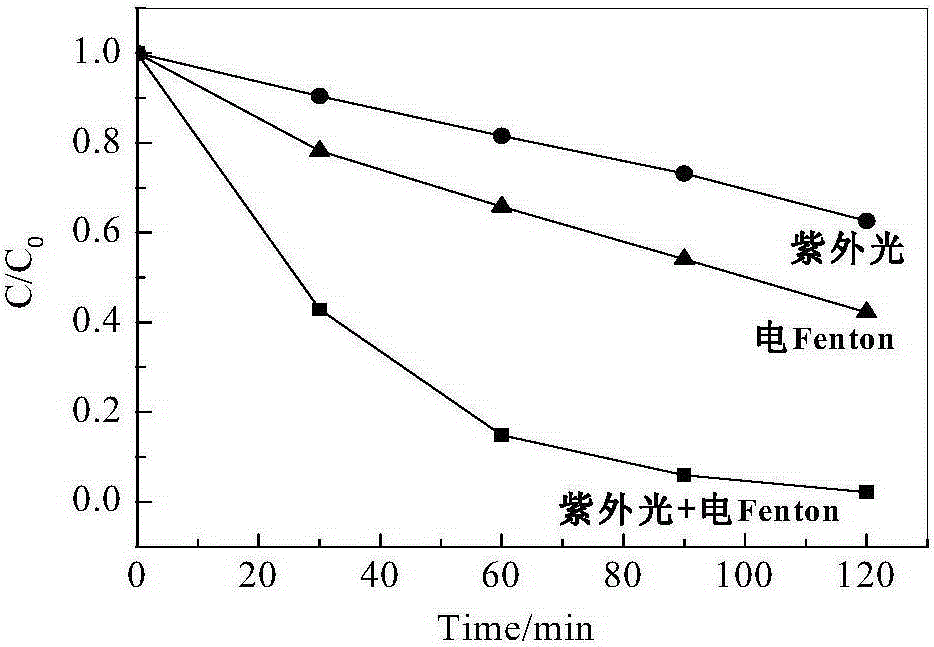

[0126] Example 1: Preparation and Application of Ultraviolet Light Synergistic Electro-Fenton System No.1

[0127] Weigh 10g flake graphite, add 0.1mL "OP" emulsifier (purchased from Jiangsu Hai'an Petrochemical Factory), 3mL absolute ethanol and 1.0g polytetrafluoroethylene, and ultrasonically disperse evenly until the mixture forms a cohesive paste. Roll the paste into a film of about 2.5mm, attach the upper and lower sides of the film to a stainless steel mesh, press it under a pressure of 30MPa to obtain an electrode, soak it in acetone solution for 2 hours to remove the residual ethanol and "OP" emulsifier on the electrode surface. Keep warm at 80°C for 2 hours in an infrared box to make a graphite electrode, and its final size: bottom area × height = 1.0cm 2 ×5mm.

[0128] The prepared cathode electrode was used as the cathode, the platinum sheet was used as the anode, and sodium sulfate (10 g / L) was used as the supporting electrolyte to obtain an electro-Fenton system....

Embodiment 2

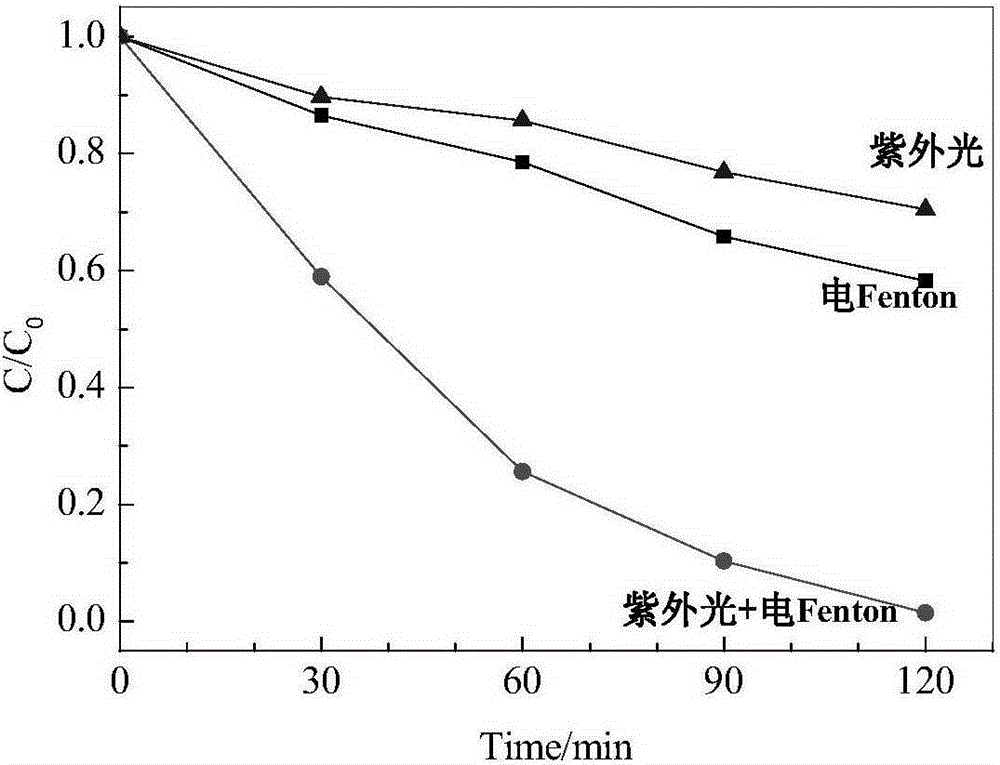

[0133] Example 2: Preparation and Application of Ultraviolet Light Synergistic Electro-Fenton System No.2

[0134] Weigh 9g of carbon nanotubes, add 0.1mL of "OP" emulsifier (purchased from Jiangsu Haian Petrochemical Factory), 2mL of absolute ethanol and 1.2g of polytetrafluoroethylene, and ultrasonically disperse evenly until the mixture forms a cohesive paste , Roll the paste into a film of about 2.5mm, attach it to a metal nickel mesh, press it under a pressure of 30MPa to obtain an electrode, soak it in acetone solution for 2h to remove the residual ethanol and "OP" emulsifier on the electrode surface. Keep warm at 80°C for 2 hours in an infrared box, and then the carbon nanotube electrode is prepared, and its final size: bottom area × height = 1.0cm 2 ×5mm.

[0135] The prepared cathode electrode was used as the cathode, the platinum sheet was used as the anode, and potassium sulfate was used as the supporting electrolyte to obtain an electro-Fenton system.

[0136] Du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com