A preparation method and application of an inorganic modified membrane based on in-situ reduction

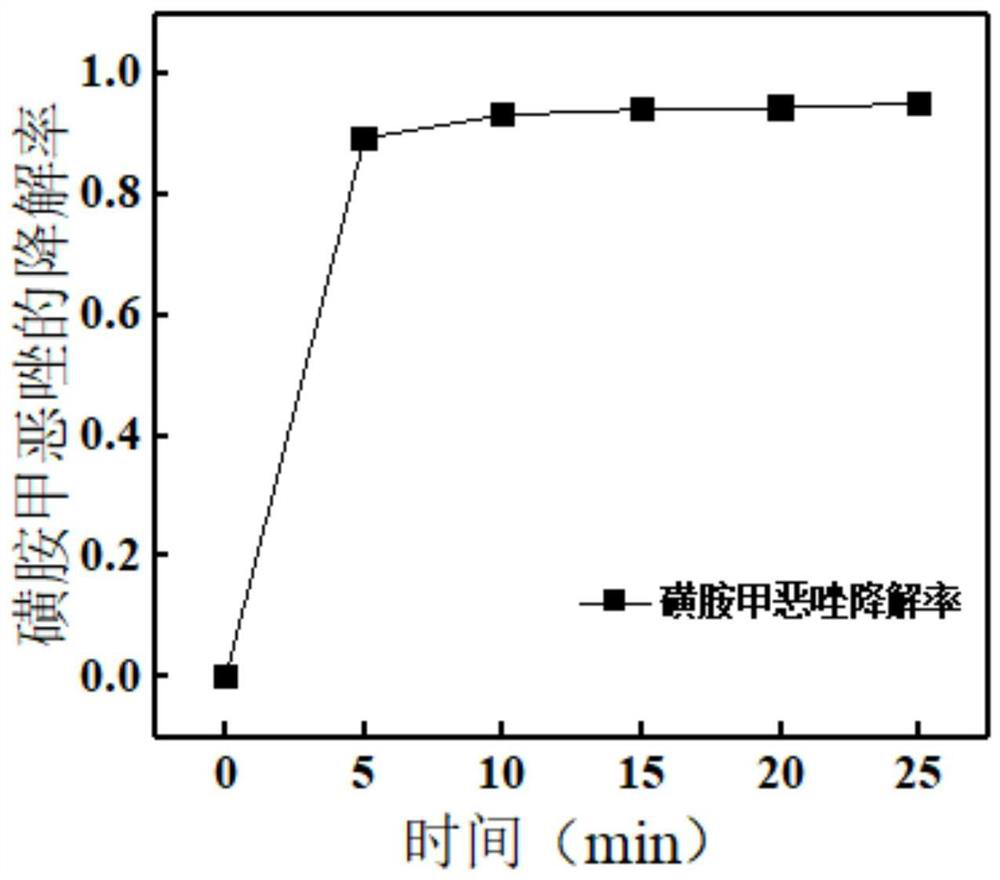

An inorganic modification, inorganic membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of inability to remove small molecular organics, secondary pollution, increase costs, etc., and achieve rapid and efficient degradation. , The effect of saving the amount of use and prolonging the time of film use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

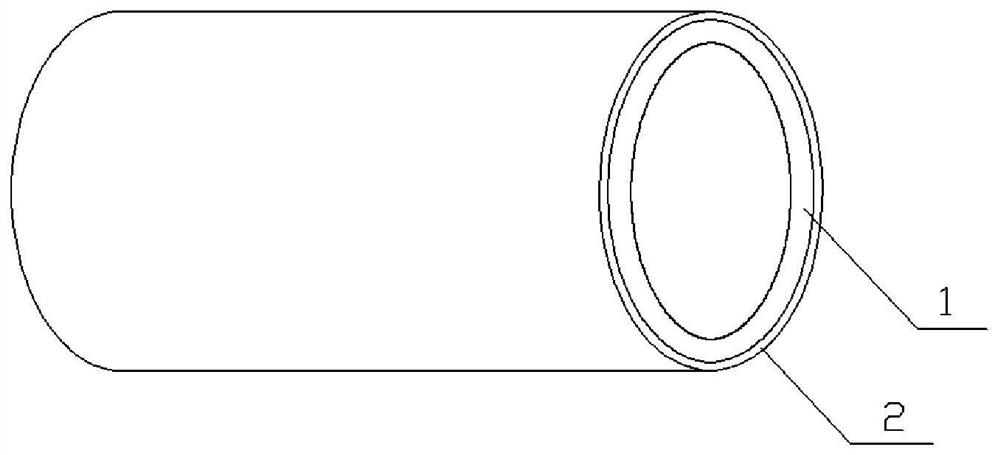

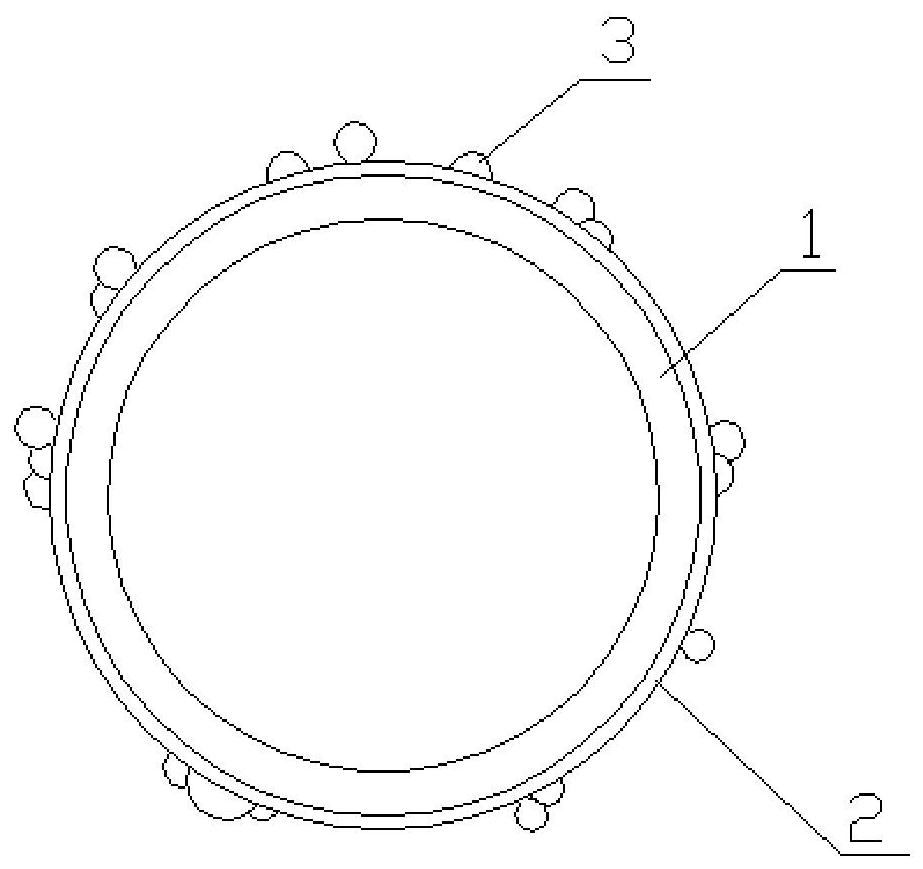

[0035] Embodiment 1: This embodiment is a method for preparing an inorganic modified membrane based on in-situ reduction, which is completed in the following steps:

[0036] 1. Preparation of catalyst support layer:

[0037] Adding an organic substance with a loading function to the buffer solution to obtain a loading layer solution;

[0038] The buffer solution described in step 1 is obtained by dissolving the buffer into water, wherein the concentration of the buffer is 0.1mmol / L-25mmol / L;

[0039] The organic matter with loading function described in step 1 is one of trimesic acid, chitin, chitosan, cellulose, glucose, fructose, galactose and glutamic acid or a mixture of several of them;

[0040] 2. Using method 1, method 2 or method 3 to load a loading layer on the surface of the inorganic membrane to obtain an inorganic membrane loaded with a loading layer, and then calcining to obtain a modified inorganic membrane;

[0041] The calcination temperature described in ste...

specific Embodiment approach 2

[0056] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the buffering agent described in step one is a mixture of boric acid and borax, a mixture of citric acid and sodium citrate, a mixture of acetic acid-sodium acetate, diphosphate A mixture of sodium hydrogen-disodium hydrogen phosphate, tris hydrochloride or a mixture of borax and sodium hydroxide. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0057] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the molar ratio of boric acid and borax in the mixture of described boric acid and borax is 1: (1~70); Described citric acid The mol ratio of citric acid and sodium citrate in the mixture of sodium citrate and sodium citrate is (1~20):(1~20); The mol ratio of acetic acid and sodium acetate in the mixture of described acetic acid-sodium acetate is (1~20). 10): (1~20); the molar ratio of sodium dihydrogen phosphate to disodium hydrogen phosphate in the mixture of sodium dihydrogen phosphate-disodium hydrogen phosphate is (1~15):(1~20); The mol ratio of borax and sodium hydroxide in the mixture of borax and sodium hydroxide is (1~5):1. Other steps are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com