Treating method for high-salinity pharmaceutical wastewater

A pharmaceutical wastewater and treatment method technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as refractory degradation, achieve strong biological toxicity, and improve the biochemical properties of wastewater The effect of stability and water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

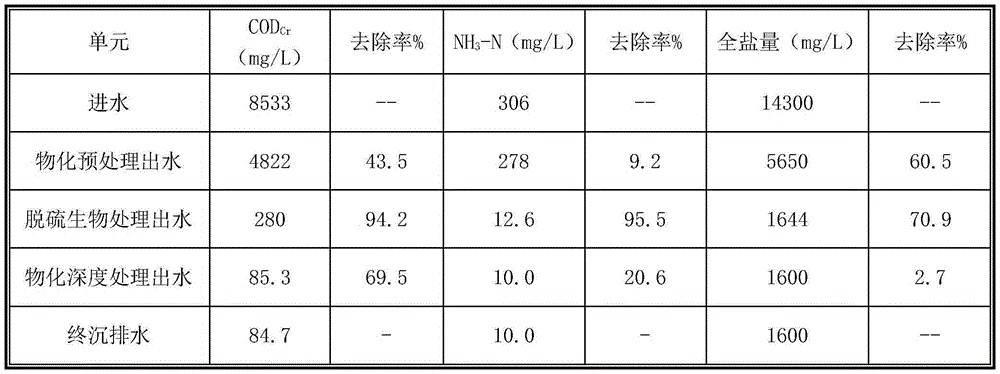

[0042]A pharmaceutical factory mainly produces chemically synthesized pharmaceuticals, pharmaceutical intermediates, and semi-synthetic antibiotics. The wastewater produced mainly comes from production processes such as extraction, centrifugation, filtration, distillation, and salt washing. The types of pollutants are complex, and the concentration of COD and sulfate is high. . The water quality indicators are shown in Table 1. Adopt processing method of the present invention to process, operate as follows:

[0043] High-salt pharmaceutical wastewater enters the catalytic micro-electrolytic cell, the mass ratio of iron-carbon-metal is 12:3:4, and the metal is a composition of aluminum and copper with a mass ratio of 1:1, and the dissolved oxygen concentration is 1.0mg / L , the reaction time is 90 minutes; after the reaction, the waste water enters the desulfurization tank Ⅰ, the molar ratio of the amount of lime added to the sulfate radical in the water is 2:1, and the effluen...

Embodiment 2

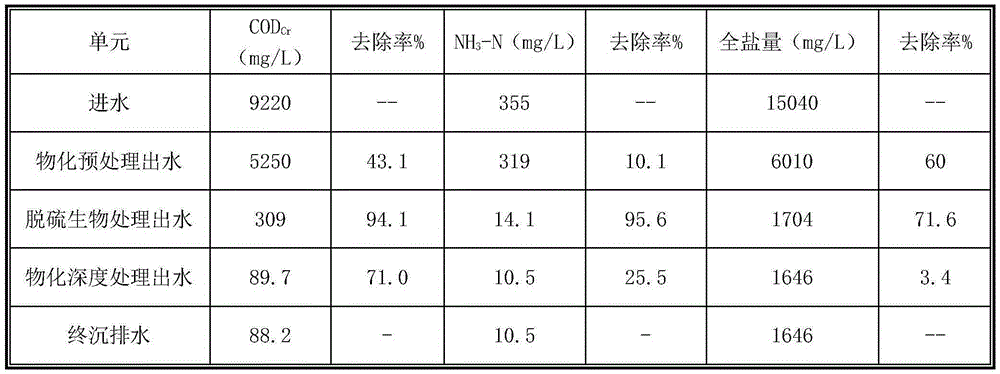

[0048] A pharmaceutical factory mainly produces antibiotics and antineoplastic drugs. The wastewater produced mainly comes from production processes such as extraction, centrifugation, filtration, distillation, and salt washing. The types of pollutants are complex, and the concentrations of COD and sulfate are high. The water quality indicators are shown in Table 2. Adopt processing method of the present invention to process, operate as follows:

[0049] High-salt pharmaceutical wastewater enters the catalytic micro-electrolytic cell, the mass ratio of iron-carbon-metal is 15:7:8, the metal is a composition of aluminum and zinc-copper in a mass ratio of 1:1, and the dissolved oxygen concentration is 1.5mg / L, the reaction time is 120min; after the reaction is completed, the wastewater enters the desulfurization tank I, the molar ratio of the amount of lime added to the sulfate radical in the water is 4:1, and the effluent enters the sedimentation tank for precipitation; the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com