Pretreatment method for increasing yield of excess sludge anaerobic digestion methane

A technology of excess sludge and anaerobic digestion, which is applied in the direction of sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problem of no combination of microwave and calcium peroxide, and achieve the mature and easy operation of microwave technology, and promote Dissolution, beneficial to the effect of subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

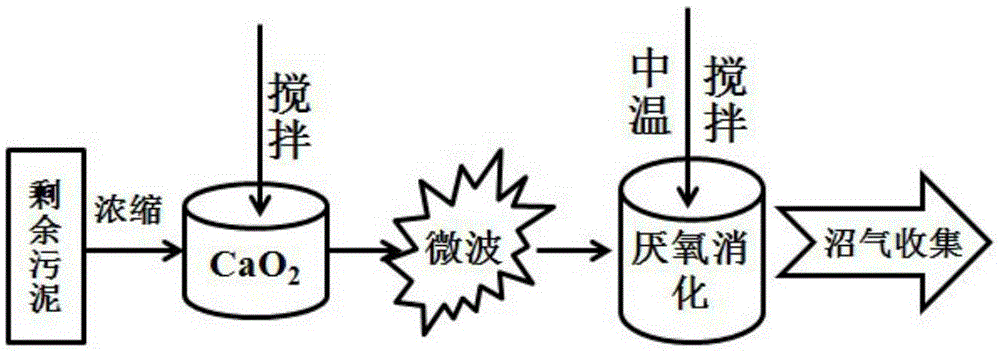

Method used

Image

Examples

Embodiment 1

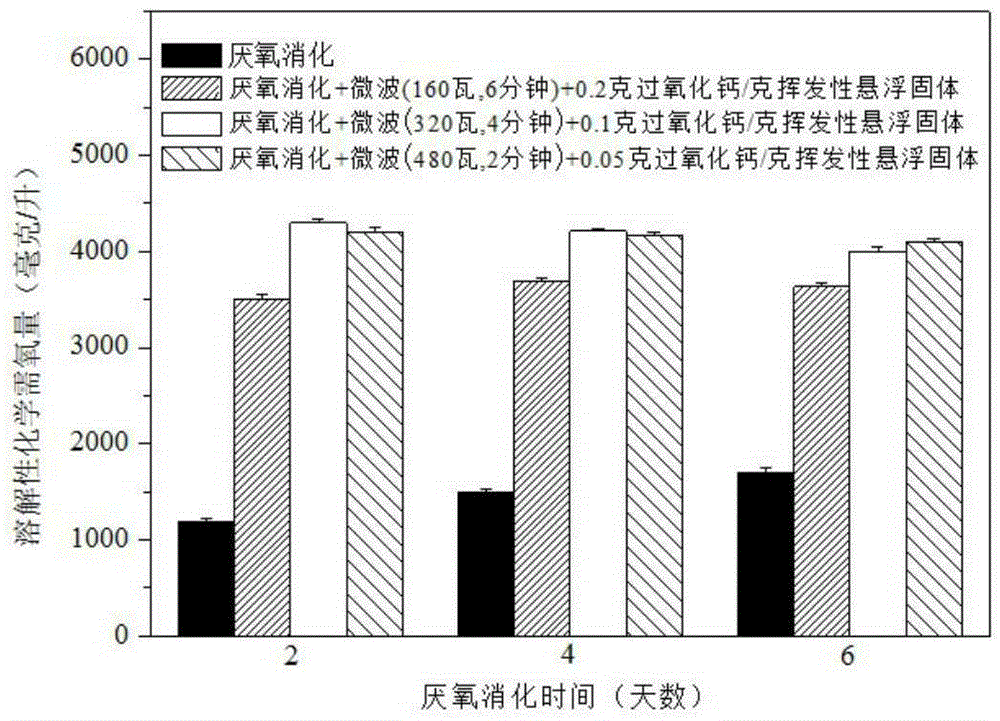

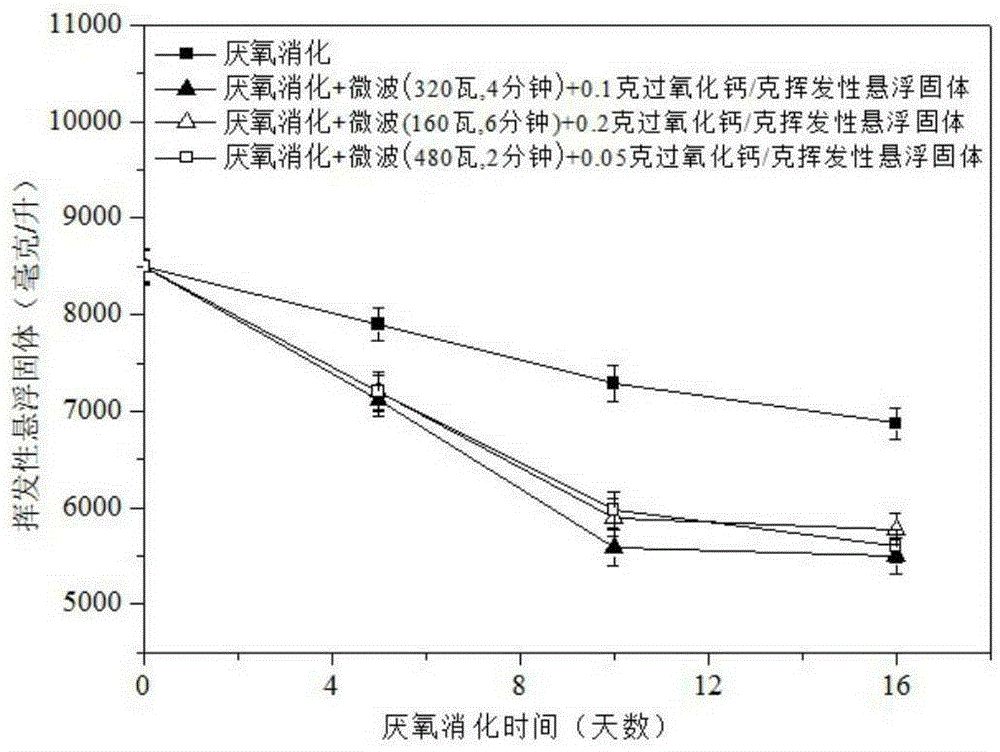

[0024] Concentrate the remaining sludge discharged from the sewage treatment plant to VSS=8.5g / L, (TSS is about 12.9g / L, pH is about 6.9), add commercially available analytically pure calcium peroxide, and the dosage of calcium peroxide is Add 0.2g of calcium peroxide to the volatile suspended solids, stir evenly, and place it under 160W microwave radiation for 6 minutes. The treated sludge is sealed and placed in an anaerobic digestion tank with a temperature of 35°C and a stirring speed of 150rpm for anaerobic digestion. Aerobic fermentation, anaerobic digestion days are 16 days. In addition, the above-mentioned excess sludge was subjected to anaerobic fermentation under the same operating conditions without adding calcium peroxide, without microwave treatment, and as a blank anaerobic digestion group. The results show that the combined use of microwave and calcium peroxide of the present invention has a better dissolving effect on sludge, and it is shown that the discharge ...

Embodiment 2

[0026] Concentrate the remaining activated sludge discharged from the sewage treatment plant to VSS=8.5g / L, (TSS is about 12.9g / L, pH is about 6.9), add commercially available analytically pure calcium peroxide, and the dosage of calcium peroxide is For every gram of volatile suspended solids, add 0.1g of calcium peroxide, stir evenly, and place it under 320W microwave radiation for 4 minutes. The treated sludge is sealed and placed in an anaerobic digestion tank with a temperature of 35°C and a stirring speed of 150rpm. Anaerobic digestion, the number of days for anaerobic digestion is 16 days. The blank group did not add calcium peroxide, did not carry out microwave treatment, and other operating conditions were the same. The results show that the combined use of microwave and calcium peroxide has a better effect on sludge dissolution, and the release of dissolved chemical oxygen demand in the microwave / calcium peroxide group reaches 4295mg / L, 4209mg / L and 4000mg / L, higher ...

Embodiment 3

[0028] A certain volume of residual activated sludge discharged from the sewage treatment plant is concentrated to VSS=8.5g / L, (TSS is about 12.9g / L, pH is about 6.9), and commercially available analytically pure calcium peroxide is added, and calcium peroxide is added The amount is to add 0.05g of calcium peroxide per gram of volatile suspended solids, stir evenly and place it under 480W microwave radiation for 2 minutes. The treated sludge is sealed and placed in an anaerobic fermentation tank with a temperature of 35°C and a stirring speed of 150rpm Anaerobic fermentation was carried out in , and the fermentation days were 16 days. In the anaerobic digestion group, calcium peroxide was not added, microwave treatment was not performed, and other operating conditions were the same. The results show that the combined use of microwave and calcium peroxide has a better effect on sludge dissolution, and the release of dissolved chemical oxygen demand in the microwave / calcium pero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com