Algae mud decorative wall material coating and preparation method and application thereof

A technology of seaweed mud and wall materials, applied in the direction of coating, etc., can solve the problems of screen sticking, poor printing effect, easy blockage of screen printing mesh, sticking screen and incomplete printing, etc., to achieve complete printing effect and overcome sticking The effect of less screen and printing times and improved affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

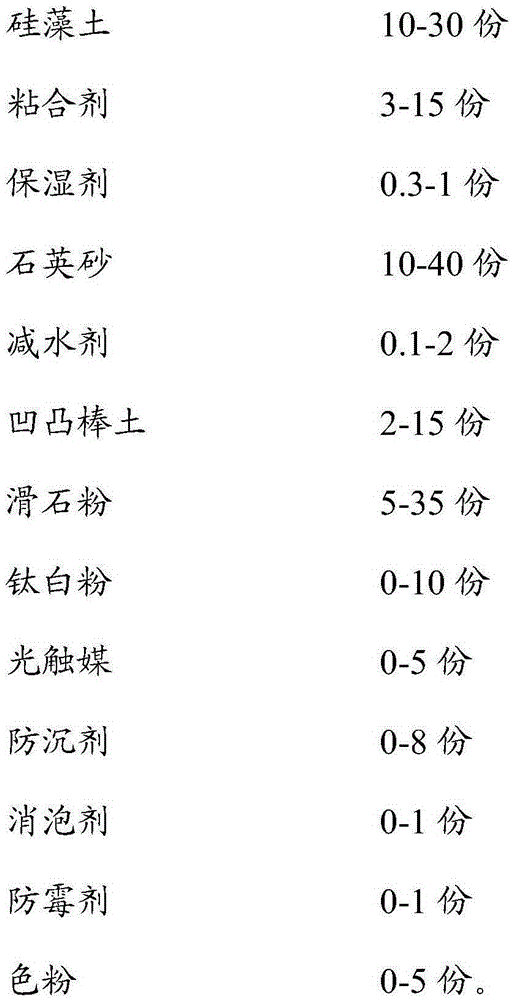

[0049] A seaweed mud decorative wall material coating is prepared from the following raw materials in parts by weight:

[0050]

[0051] The above-mentioned quartz sand is high-whiteness quartz sand with a particle size higher than 600 mesh, and the above-mentioned talc powder is ultrafine talc powder with a particle size higher than 800 mesh.

[0052] The preparation method of the seaweed mud coating of the present embodiment is as follows:

[0053] Weigh each raw material according to the above parts by weight, add it to a high-speed mixer and stir at high speed for 10-30 minutes, take a small amount of sample for testing, after stirring evenly, filter and pack it with a 100-mesh vibrating screen, and pack it in a sealed bag to obtain the product.

[0054] The using method of the seaweed mud coating of the present embodiment is as follows:

[0055] Remove the seaweed mud paint packaged in the above-mentioned sealed bag, mix the seaweed mud paint with water according to t...

Embodiment 2

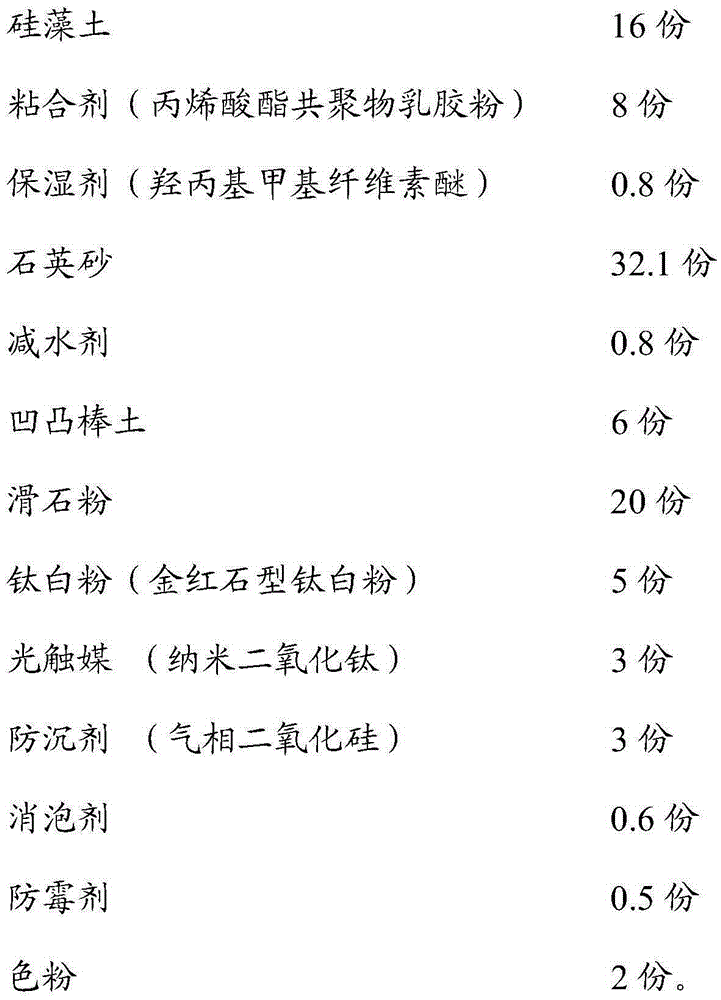

[0057] A seaweed mud decorative wall material coating is prepared from the following raw materials in parts by weight:

[0058]

[0059] The seaweed mud decorative wall material coating of this example is prepared according to the method of Example 1, and the printing construction is carried out according to the method of Example 1.

Embodiment 3

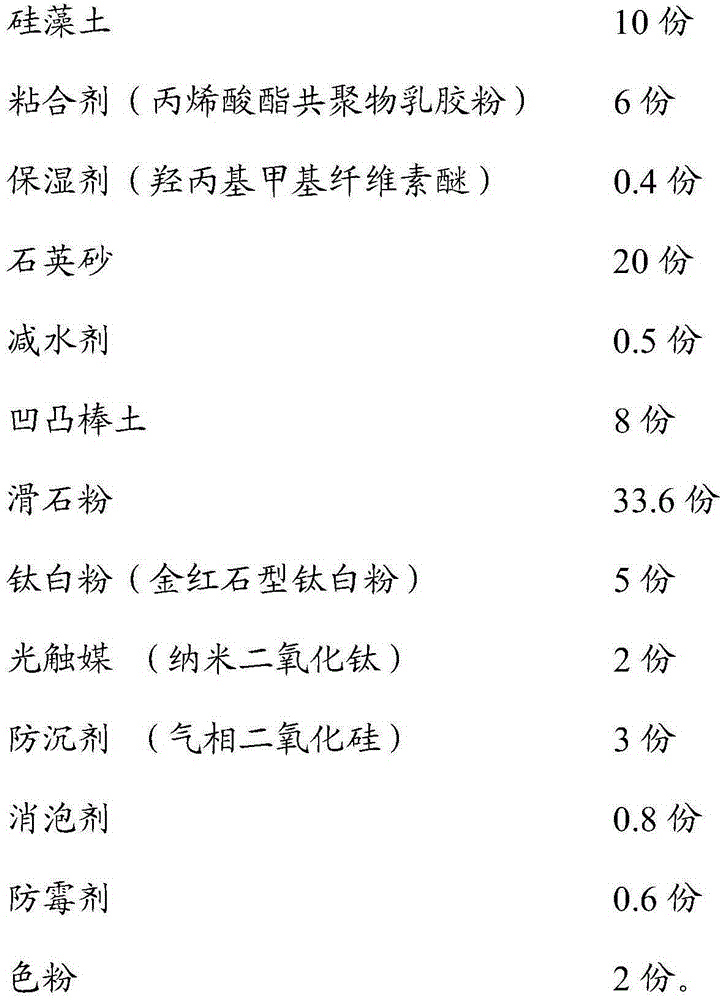

[0061] A seaweed mud decorative wall material coating is prepared from the following raw materials in parts by weight:

[0062]

[0063] The seaweed mud decorative wall material coating of this example is prepared according to the method of Example 1, and the printing construction is carried out according to the method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com