Cartilage tissue engineering scaffold and preparation method thereof

A cartilage tissue and engineering technology, applied in the field of cartilage tissue engineering scaffolds and their preparation, can solve the problems of poor mechanical strength, poor mechanical strength of cartilage tissue engineering scaffolds, limited ability to recruit bone marrow mesenchymal stem cells, etc., to improve durability, The effect of strong cartilage tissue repair ability and convenient large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

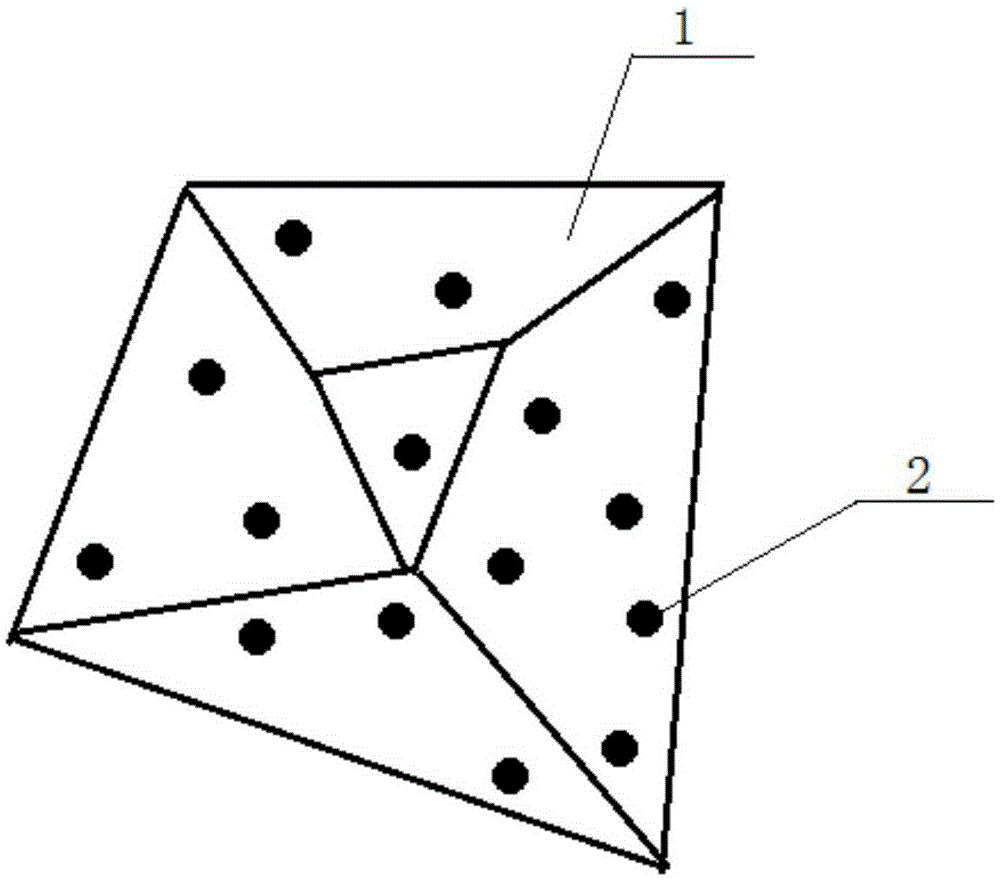

[0046] On the other hand, the embodiment of the present invention also provides the preparation method of the above-mentioned cartilage tissue engineering scaffold, comprising: preparing at least one decalcified cortical bone matrix microsphere 2 with a diameter of 500-800 μm; adding bone marrow mesenchymal stem cell affinity peptide modifying at least one surface of decalcified cortical bone matrix microsphere 2, and adding the decalcified cortical bone matrix microsphere 2 modified with bone marrow mesenchymal stem cell affinity peptide into the chitosan hydrogel solution, at 32-38°C The gelation reaction is carried out for 28-32 minutes, preferably 30 minutes, to obtain the cartilage tissue engineering scaffold.

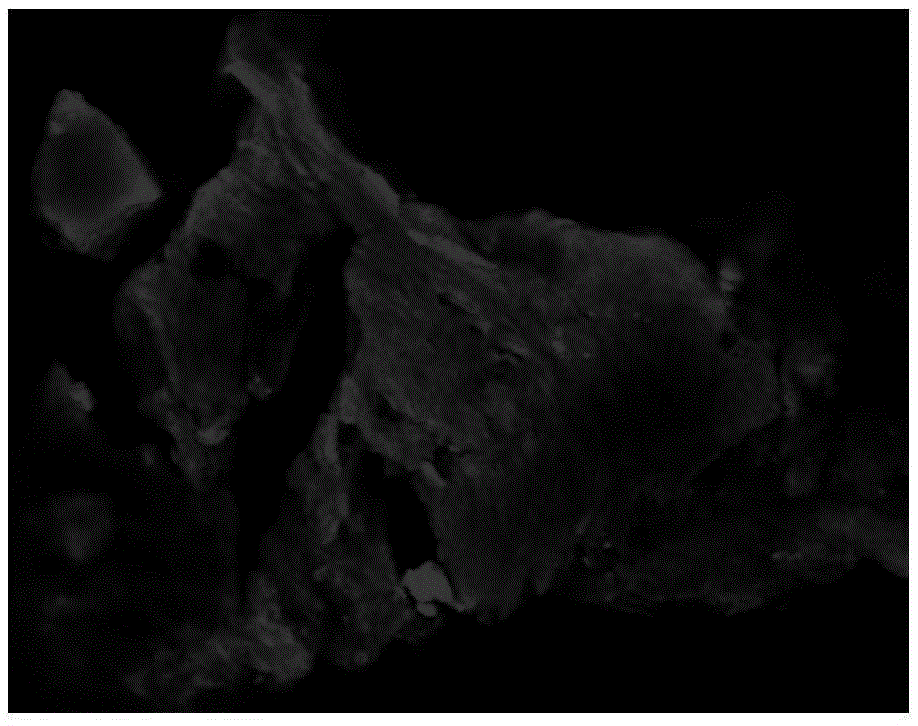

[0047] Specifically, the preparation method of decalcified cortical bone matrix microspheres 2 is as follows: remove the soft tissue attached to the femur, such as muscle and fascia, obtain the cortical bone of the femur, and degrease and decalcify the cortical bon...

Embodiment 1

[0052] This embodiment provides a cartilage tissue engineering scaffold, comprising a chitosan hydrogel exoskeleton 1, and at least one decalcified cortical bone matrix microstructure coated with an E7 polypeptide on the surface of the chitosan hydrogel exoskeleton 1. ball 2.

[0053] The preparation method of the cartilage tissue engineering support provided by the present embodiment is:

[0054] Step 1. Preparation of decalcified cortical bone matrix microspheres

[0055] A urethane solution with a mass concentration of 20% was prepared, and a 4Kg New Zealand white rabbit was anesthetized with an excessive amount of urethane solution. The long bones of the limbs of the white rabbit were taken out, the muscles and fascia were removed to obtain the cortical bone of the femur, and then the cortical bone was placed in a mixed solution of methanol and chloroform and defatted for 48 hours. Wherein, the volume ratio of methanol and chloroform is 1:1. The degreased cortical bone ...

Embodiment 2

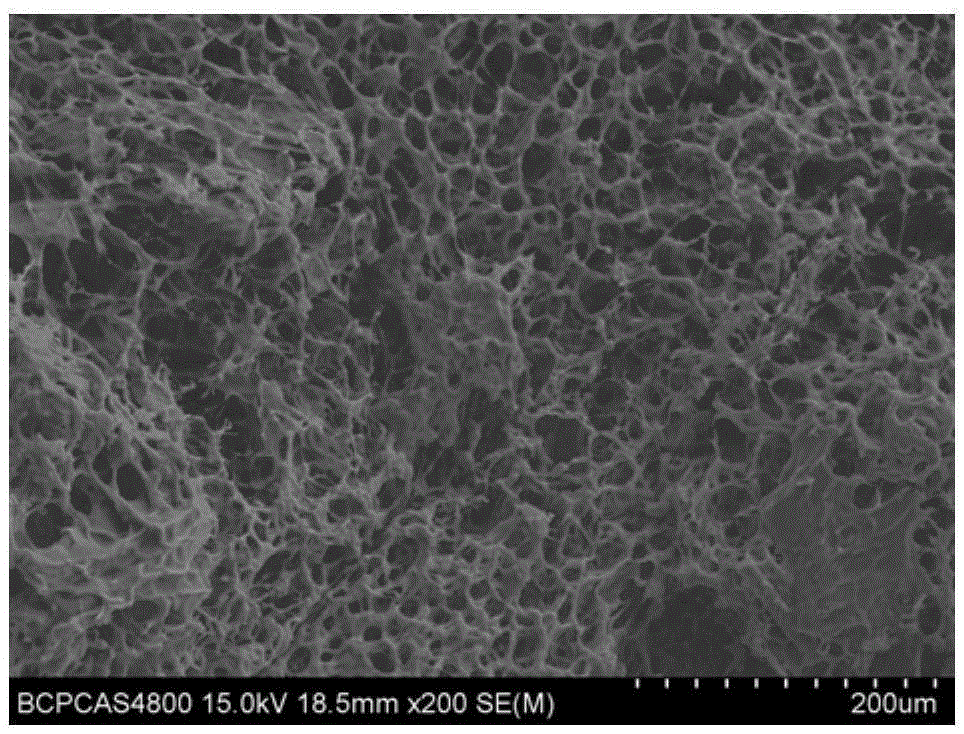

[0064] The purpose of this example is to illustrate the durability and mechanical properties of the cartilage tissue engineering scaffold provided in Example 1, and the in vitro degradation rate and equilibrium swelling ratio of the cartilage tissue engineering scaffold provided in Example 1 were determined. For the convenience of description, the cartilage tissue engineering scaffold provided in Example 1 is defined as the first scaffold 5 below. Wherein, the corresponding performances of the first comparison bracket 3 made of a single chitosan hydrogel and the second comparison bracket 4 composed of a single decalcified cortical bone matrix particle coated in a chitosan hydrogel are carried out the same The test process is used as a comparison.

[0065] The specific measurement process is as follows: firstly, the first comparison bracket 3 , the second comparison bracket 4 , and the first bracket 5 were respectively put into containers with a diameter of 2.5 mm and a height ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com