Wear-resistant antibacterial shoe material and preparation method thereof

A shoe material and polyvinyl alcohol technology, applied in footwear, applications, clothing, etc., can solve the problems of non-slip, sole discomfort, etc., and achieve good ventilation, simple processing methods, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

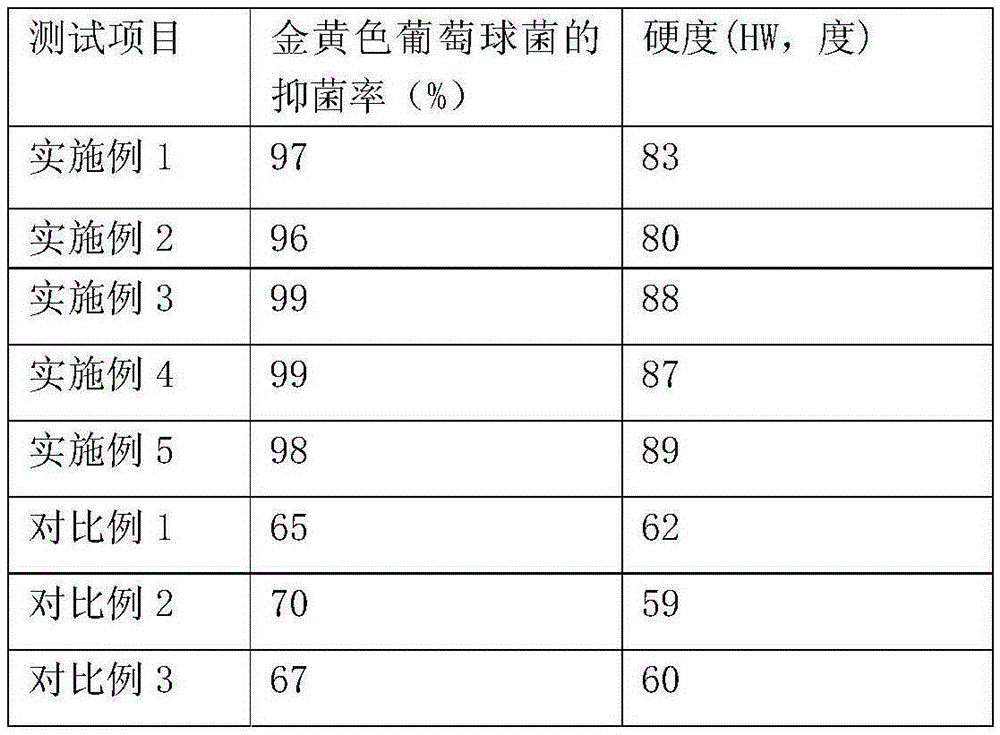

Examples

Embodiment 1

[0032] (1) Weigh 60kg of EPDM rubber, 12kg of polyvinyl alcohol with an average molecular weight of 12000, 5kg of silk protein, 3kg of polyvinyl butyral, 1kg of γ-mercaptopropyl trimethoxysilane, and methyl isobutyl ketone 1kg, pentaerythritol stearate 0.5kg, methylisothiazolinone 0.5kg, isophoronediamine 0.02kg and bis-(phenyldimethylsiloxane)methylsilanol 1kg at 40°C Stir well,

[0033] (2) Add the above components into a three-bladed mixer and mix evenly, add 2kg of zinc ricinoleate and 1kg of nano-titanium dioxide, add them to the twin-screw extruder, and add hydroxypropylmethyl at the side feeding port of the twin-screw extruder Cellulose 12kg is melted, extruded, dried, and pelletized to obtain an antibacterial and deodorant insole material.

[0034] The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 170°C, the temperature of the second zone is 1900°C, the temperature of the third zone is 2150°C, and the temper...

Embodiment 2

[0037] (1) Weigh 60kg of EPDM rubber, 12kg of polyvinyl alcohol with an average molecular weight of 12000, 5kg of silk protein, 3kg of polyvinyl butyral, 1kg of γ-mercaptopropyl trimethoxysilane, and methyl isobutyl ketone 1kg, 0.5kg of pentaerythritol stearate, 0.5kg of methylisothiazolinone and 0.02kg of isophoronediamine, stirred evenly at 40°C,

[0038] (2) Add the above components into a three-bladed mixer and mix evenly, add 2kg of zinc ricinoleate and 1kg of nano-titanium dioxide, add them to the twin-screw extruder, and add hydroxypropylmethyl at the side feeding port of the twin-screw extruder Cellulose 12kg is melted, extruded, dried, and pelletized to obtain an antibacterial and deodorant insole material.

[0039] The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 170°C, the temperature of the second zone is 1900°C, the temperature of the third zone is 2150°C, and the temperature of the fourth zone is 190°C...

Embodiment 3

[0042] (1) Weigh 70 kg of EPDM rubber, 18 kg of polyvinyl alcohol with an average molecular weight of 15,000, 8 kg of silk protein, 5 kg of polyvinyl butyral, 3 kg of γ-mercaptopropyl trimethoxysilane, and methyl isobutyl ketone 2kg, pentaerythritol stearate 1kg, methylisothiazolinone 1kg, isophorone diamine 0.2kg and bis-(phenyldimethylsiloxane) methylsilanol 1kg, stir evenly at 60°C ,

[0043] (2) Add the above components into a three-blade mixer and mix evenly, add 4kg of zinc ricinoleate and 3kg of nano-titanium dioxide, add them to the twin-screw extruder, and add hydroxypropylmethyl to the side feed port of the twin-screw extruder Cellulose 15kg is melted, extruded, dried, and pelletized to obtain an antibacterial and deodorant insole material.

[0044] The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 180°C, the temperature of the second zone is 200°C, the temperature of the third zone is 220°C, and the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com