Preparation method for aviation kerosene

A technology based on aviation kerosene and furfural, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, biological raw materials, etc., and can solve the problems of unsuitable aviation kerosene and high freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0027] 1. Preparation of catalyst:

[0028] 1) Preparation of solid base catalyst: alkaline earth oxides (MgO, CaO) are commercial catalyst products purchased directly. CeO 2 by the corresponding nitrate in N 2 Calcined under atmosphere for 8h. Alkaline earth and rare earth mixed oxides (CaO-CeO 2 , MgO-La 2 o 3 ) by co-precipitation method 20wt%NH 3 .H 2 O was added dropwise to the two nitrate solutions mixed in a certain molar ratio, the pH was adjusted to 9, stirring was continued for 1 h, dried overnight at 80 °C, and calcined at 650 °C for 8 h. Magnesium aluminum hydrotalcite is the molar ratio of 3:1 Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O mixed solution was added dropwise with NaOH and NaCO at 3mL / min 3in the mixed solution ([CO 3 ] / [Al]+[Mg]=0.53, [OH] / [Al]+[Mg]=2.33), the dropping process was carried out under strong stirring in a 70°C water bath. After the dropwise addition, continue to stir and age for 16 hours, then filter and wash, dry at 80°C o...

Embodiment 11-21

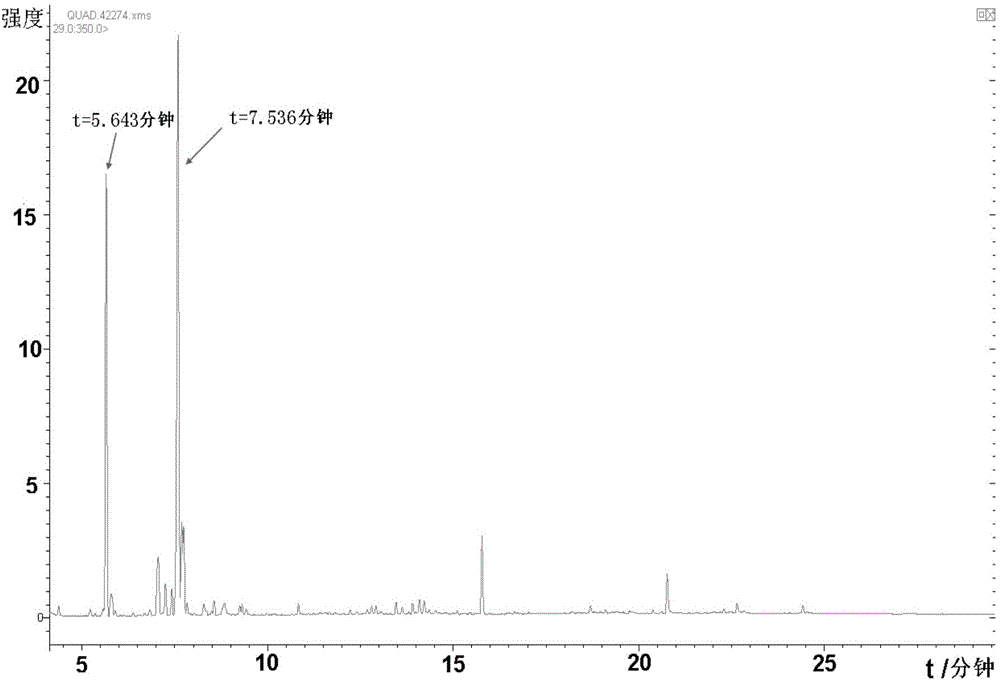

[0034] 2. Aldol condensation reaction: Add 18g furfural, 33g 3-pentanone (or lignocellulose-based furfural compounds and carbonyl-containing compounds with a molar ratio of 1:2), 3g catalyst (catalyst ratio 6wt%) in a 100mL reactor , Stirring at 170°C for 8h. The detailed reaction results are shown in Table 2.

[0035] Table 2 Aldol condensation reaction and its results

[0036]

[0037]

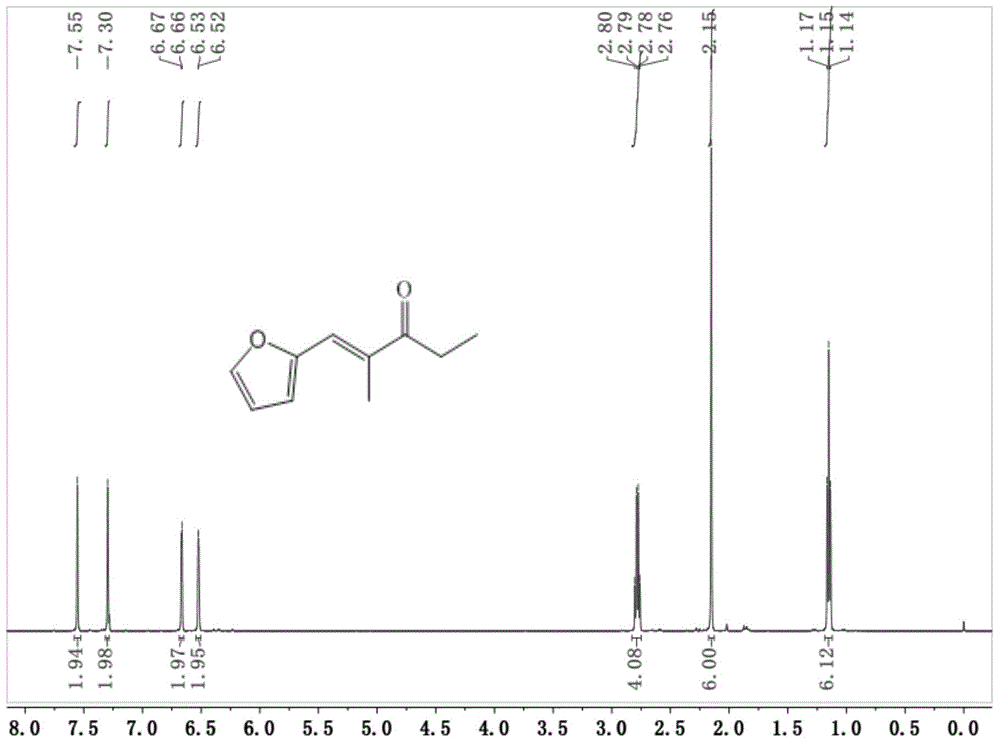

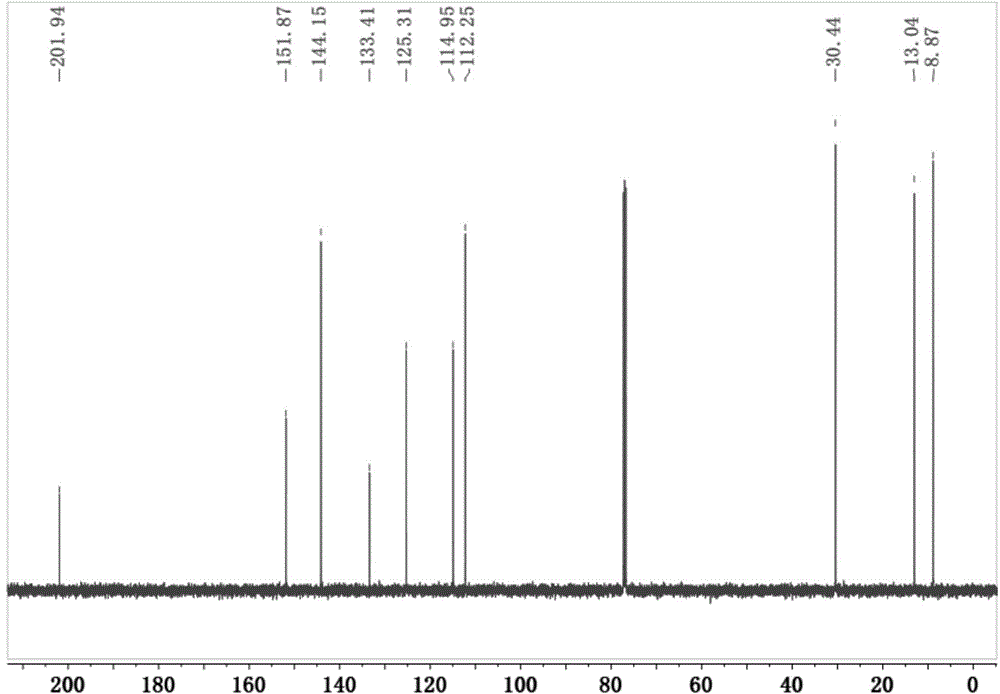

[0038] Table 3 Aldol condensation target product structural formula

[0039]

[0040] As can be seen from Table 2, in different solid base catalysts: MgO, CaO, CeO 2 , MgO-La 2 o 3 、CaO-CeO 2 , Hydrotalcite, KF / Al 2 o 3 , MgO-ZrO 2 Under the action of catalysis, there is a certain yield of aldol condensation products. Among them, CaO, KF / Al 2 o 3 The activity is the best. Because CaO is easy to prepare, cheap and easy to obtain, we choose this catalyst for in-depth research.

Embodiment 22-26

[0042] 1) The effect of different reaction substrate ratios on the yield of aldol condensation reaction products of furfural and 3-pentanone

[0043] Table 4. Effect of different reaction substrate ratios on A yield

[0044]

[0045] It can be seen from Table 4 that the yield of product A is the highest when the molar ratio of furfural to 3-pentanone is 1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com