High-purity cobalt preparation method

A high-purity, cobalt solution technology, applied in photographic process, instrument, photographic auxiliary process, etc., can solve the problems of affecting product purity, diaphragm maintenance, high renewal cost, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

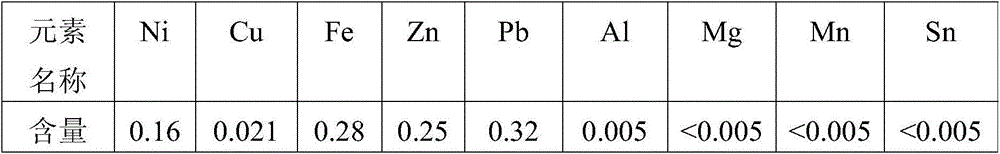

Embodiment 1

[0032] 5 liters of P507 organic extractant was added to 20 liters of sulfonated kerosene, and under stirring, 20% of P507 extractant was evenly mixed, and then 900 ml of 12N sodium hydroxide was added for saponification reaction.

[0033] Add 8 liters of cobalt chloride feed liquid, wherein the cobalt concentration is 40%, and the P507 extractant after the saponification is stirred, extracted and separated, the stirring speed is 60 rev / min, the two-phase mixing time is 15 minutes, the cobalt is extracted into the organic phase, and the P507 extractant It becomes the loaded organic phase. At this time, the color of the cobalt solution changes from rose red to blue, and the color of the organic phase changes from pale yellow to colorless.

[0034] with [H + ] is a 2.0 mol / L hydrochloric acid solution as a washing solution to wash the cobalt-loaded P507 organic phase until the pH of the aqueous phase of the washing solution is 3.5.

[0035] reuse [H + ] is 1.0 mol / L hydrochloric ...

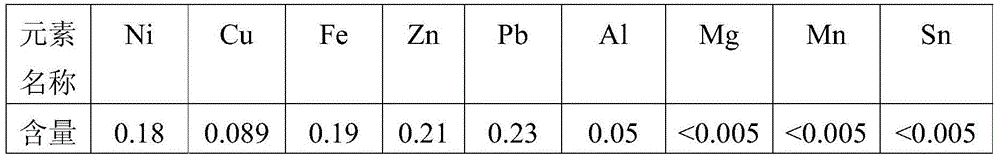

Embodiment 2

[0047] Configure 30 liters of 30% P507 extractant, and the test operation method is the same as that of Example 1. Add 15 liters of cobalt chloride feed solution, the concentration of cobalt solution is 60%, add to the P507 extractant after saponification, stir and extract and separate, stirring speed is 60 rev / min, two-phase mixing time is 15 minutes, cobalt enters the organic phase, P507 The extractant becomes the loaded organic phase. At this time, the color of the cobalt solution changes from rose red to blue, and the color of the organic phase changes from light yellow to very light pink.

[0048] with [H + ] is a 2.0 mol / L hydrochloric acid solution as a washing solution to wash the cobalt-loaded P507 organic phase until the pH of the aqueous phase of the washing solution is 3.5.

[0049] reuse [H + ] is 1.0 mol / L hydrochloric acid solution as the back-extracting liquid to back-extract the cobalt in the loaded organic phase into the aqueous phase, until the pH of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com