Manufacturing method of quantum dot color film substrate

A technology of color film substrate and production method, which is applied in the field of quantum dot color film substrate production, can solve the problems of quantum dot layer patterning, low resolution of quantum dot graphics, and inability to mass-produce, etc., so as to improve color saturation Effects with color gamut, enhanced color performance, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

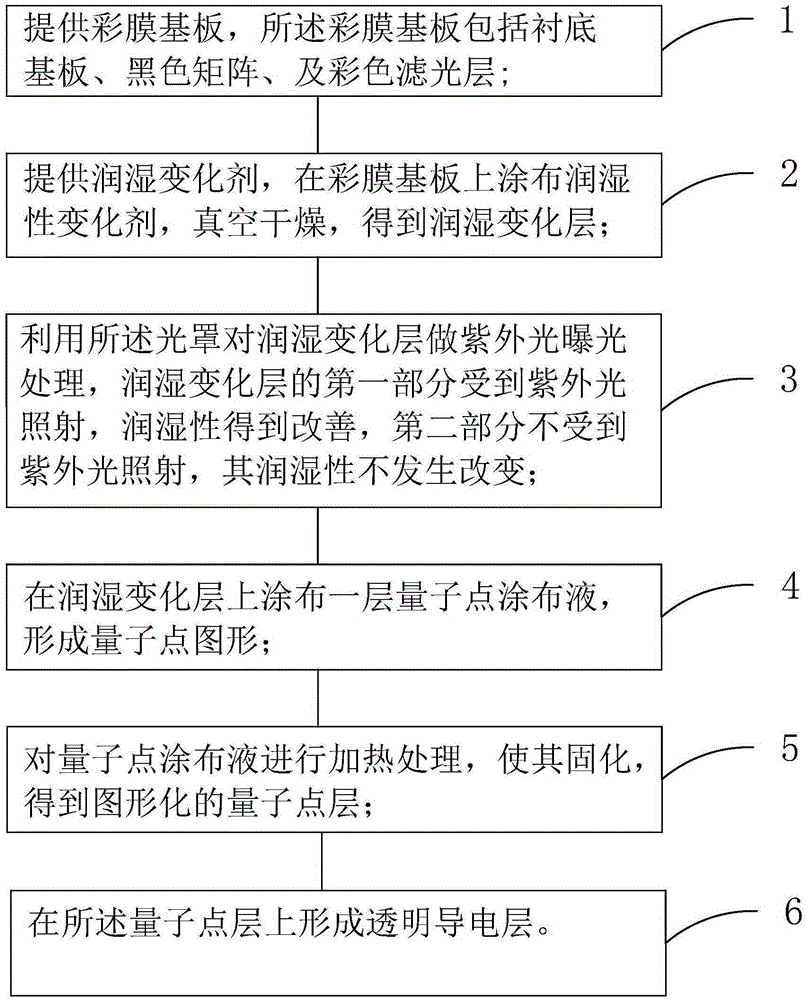

[0033] see figure 1 , the invention provides a method for manufacturing a quantum dot color film substrate, comprising the following steps:

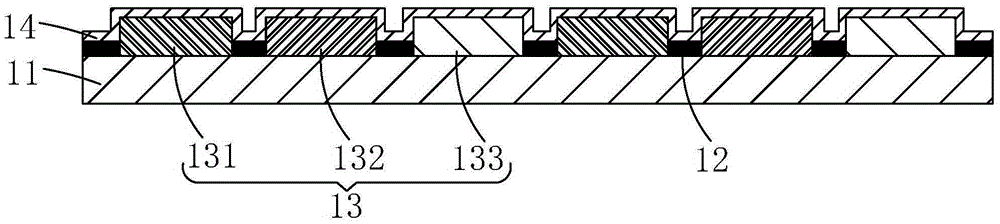

[0034] Step 1. Provide a color filter substrate, the color filter substrate includes a base substrate 11, a black matrix 12 located on the base substrate 11, and a color filter layer 13, and the color filter layer 13 includes a red color resist Layer 131, green color resist layer 132, and transparent photoresist layer 133;

[0035] Specifically, the base substrate 11 is a glass substrate.

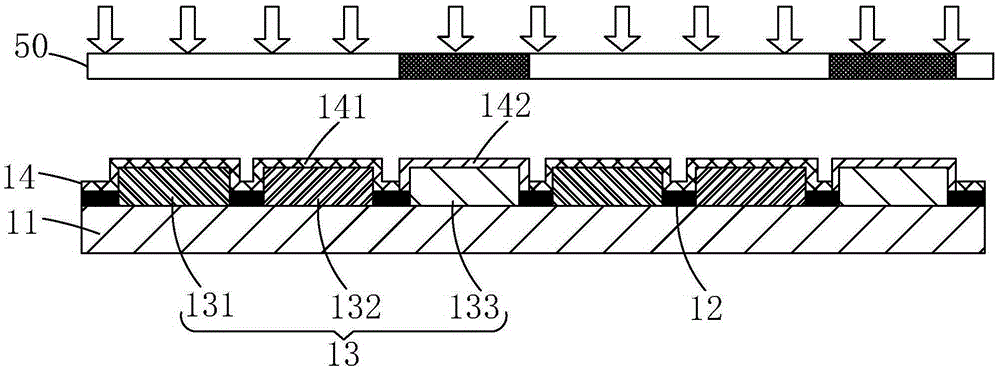

[0036] Step 2, providing a wettability change agent, which includes the following components: photocatalyst, organopolysiloxane, and solvent; as figure 2 As shown, a layer of wettability changing agent is coated o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com