Honeycomb rotating wheel with combination of adsorbent purification and catalytic oxidation for VOCs

A catalytic oxidation and runner technology, applied in chemical instruments and methods, separation of dispersed particles, air quality improvement, etc., can solve the problems of large footprint, complex equipment, high cost, etc., and achieve small footprint and compact equipment structure , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The concrete preparation method of the honeycomb runner of above-mentioned two runner structures, comprises the following steps:

[0031] Step 1. Select one or more mixtures of ceramic fiber, glass fiber, synthetic fiber or natural fiber to make paper, and extrude it into paper with concave-convex surface after papermaking. The paper with concave-convex surface is made of inorganic adhesive A binder such as silica sol or aluminum sol is bonded on flat paper to form a layered body, and the layered body is stacked or wound into a honeycomb profile;

[0032] Step 2, cutting the obtained profile into a desired shape, heating to remove part of the organic matter, and obtaining two carriers with a porous honeycomb structure as runner one and runner two;

[0033] Step 3: Mix 0.1-30 parts of molecular sieve, 0.1-30 parts of catalyst with 0.1-30 parts of inorganic binder and 10-60 parts of water to obtain adsorbent slurry and catalyst slurry;

[0034] Step 4, attaching the obta...

Embodiment 1

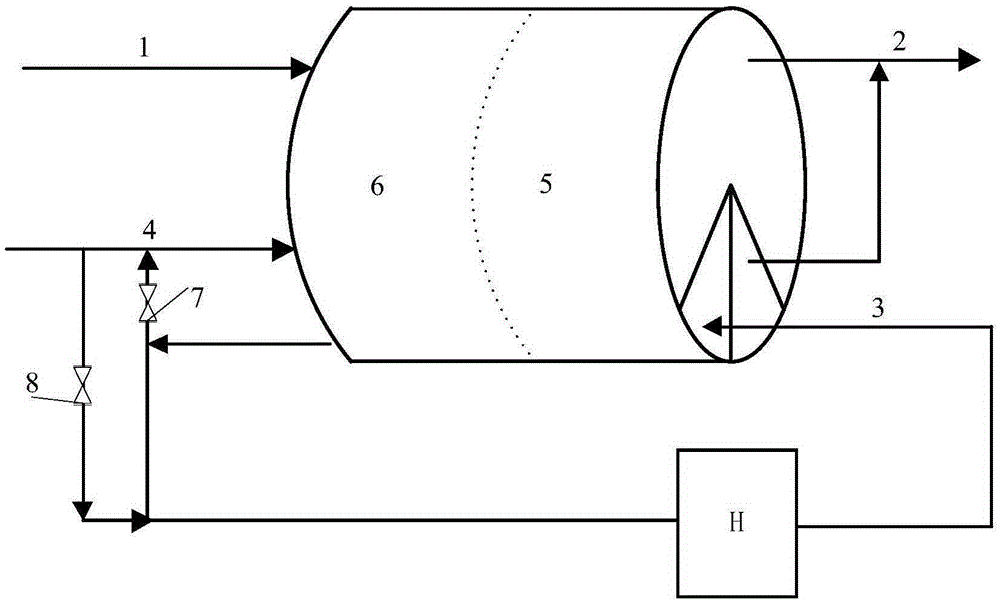

[0043] In this embodiment, combined with figure 1 As shown, the process of adsorption and purification of VOCs and catalytic oxidation through the honeycomb runner includes:

[0044] Step 1. VOCs1 are first adsorbed and concentrated through the adsorption zone 5, and the waste gas is purified and emptied 2;

[0045] Step 2. The runner gradually tends to adsorption saturation. In the desorption zone, high-temperature air (open valve 28 and heat the air through the heater) passes through the saturated runner, and the adsorbed waste gas is desorbed 3 and directly enters the Catalytic zone 6 carries out catalytic oxidation process;

[0046] Step 3. The gas after catalytic oxidation carries part of the heat, which can be used as desorption gas to save part of the heat;

[0047] Step 4, the runner is cooled by the atmosphere 4, so that the runner can continuously perform the process of adsorption purification and catalytic oxidation.

[0048] The heat balance of the system in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com