Catalyst for catalytic combustion of chloralkane, preparation method and application thereof

A technology of catalytic combustion and chlorinated alkanes, which is applied in the direction of combustion methods, physical/chemical process catalysts, chemical instruments and methods, etc., to improve the anti-chlorine poisoning performance, increase the content of active oxygen species and oxygen mobility, and facilitate oxidation detoxification The effect of removing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

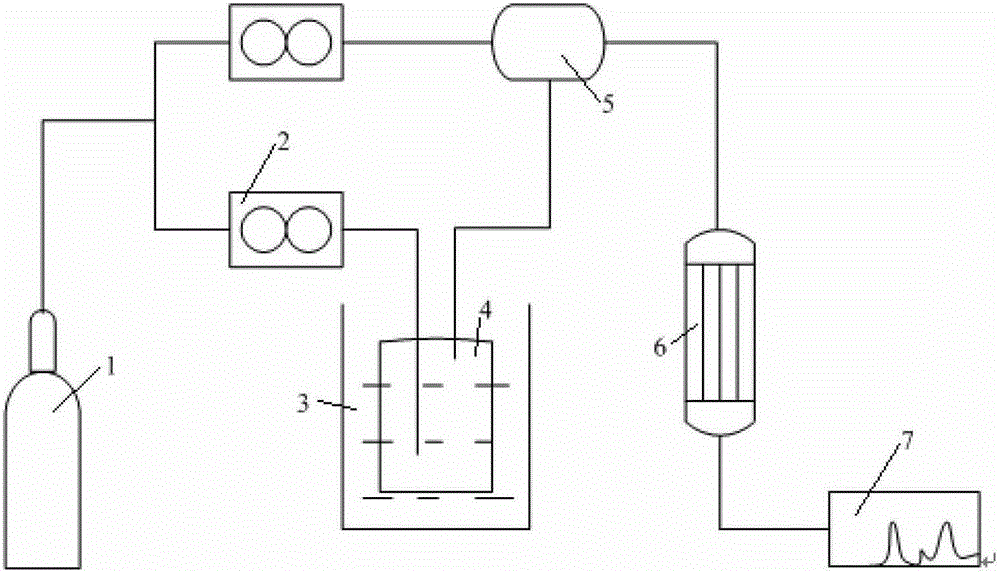

Method used

Image

Examples

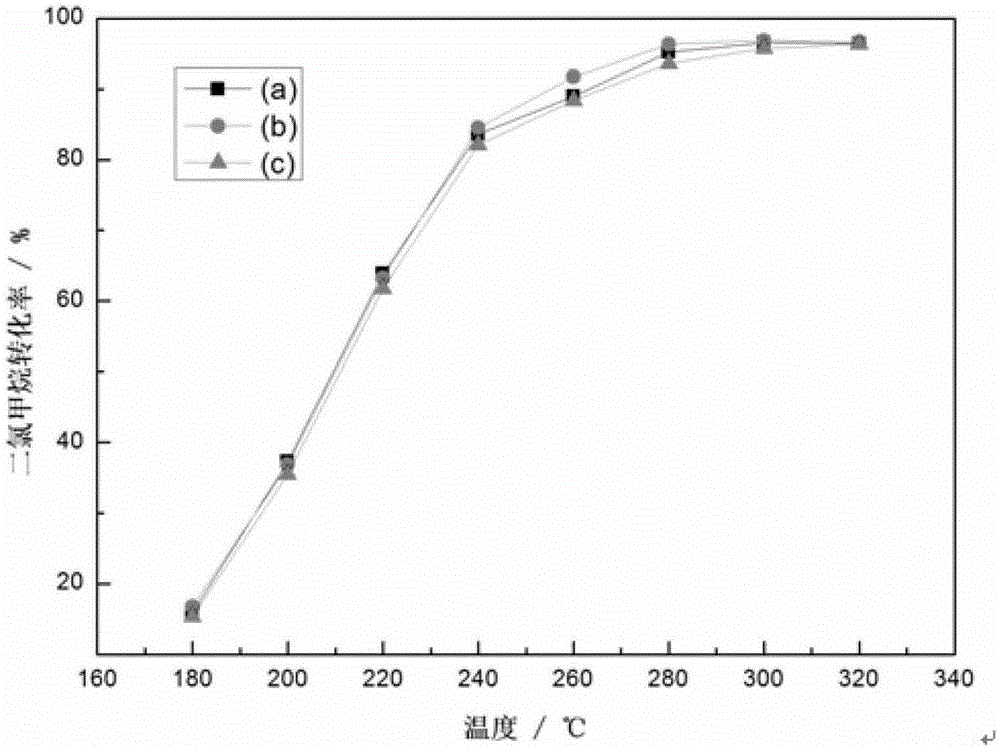

Embodiment 1-3

[0037] This embodiment 1-3 is the component and content of the catalyst of catalytic combustion chlorinated alkanes of the present invention, specifically see following table 1:

[0038] Table 1

[0039] Example MnO x -SrO 2 The mass percentage of composite oxides in the catalyst SrO 2 % of active ingredient TiO 2 -ZrO 2 The mass percentage of composite oxides in the catalyst Ti / Zr value of x Example 1 3wt% 10wt% 97wt% 1 2, 3 or 4 Example 2 5wt% 30wt% 95wt% 1 2, 3 or 4 Example 3 10wt% 50wt% 90wt% 1 2, 3 or 4

Embodiment 4

[0041] The preparation method of the catalyst of above-mentioned embodiment 1-3 comprises the following steps:

[0042] (1) Dissolve a certain amount of manganese nitrate and strontium nitrate in a certain concentration of oxalic acid solution, and mix after the solution is fully dissolved;

[0043] (2), add pre-prepared TiO to the mixed solution in step (1) 2 -ZrO 2 Composite oxide carrier, stirred evenly, impregnated for 24 hours;

[0044] (3) Dry the mixture in step (2) at 110°C for 12 hours;

[0045] (4) Put the dried product of step (3) into a muffle furnace and calcinate for 3 hours at 400°C in the air, and then grind and sieve to obtain a catalyst. The catalyst is expressed as: (MnO x ) m -(SrO 2 )n / Ti 0.5 Zr 0.5 , where m and n represent MnO x and SrO 2 Accounting for the mass fraction of the catalyst, X is a positive integer greater than 2. The catalyzer as embodiment 1 is (MnO x ) 0.027 -(SrO 2 ) 0.003 / Ti 0.5 Zr 0.5 , the catalyst of embodiment 2 is ...

Embodiment 5

[0047] The catalyst of above-mentioned embodiment 1-3 can also be made through the following steps:

[0048] (1) Dissolve a certain amount of manganese nitrate and strontium nitrate in a certain concentration of hydrochloric acid solution, and mix after the solution is fully dissolved;

[0049] (2), add pre-prepared TiO to the mixed solution in step (1) 2 -ZrO 2 Composite oxide carrier, stirred evenly, impregnated for 36 hours;

[0050] (3) Dry the mixture in step (2) at 90°C for 10 hours;

[0051] (4) Put the dried product of step (3) into a muffle furnace for calcination at 350° C. in air for 2 hours, and then grind and sieve to obtain a catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com