Preparing method for manganese zinc ferrite material and processing device of manganese zinc ferrite material

A technology of manganese-zinc ferrite and processing equipment, which is applied in the field of machinery, can solve problems such as complexity, many production processes, and low production efficiency, and achieve the effects of stable crushing process, high crushing efficiency, and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

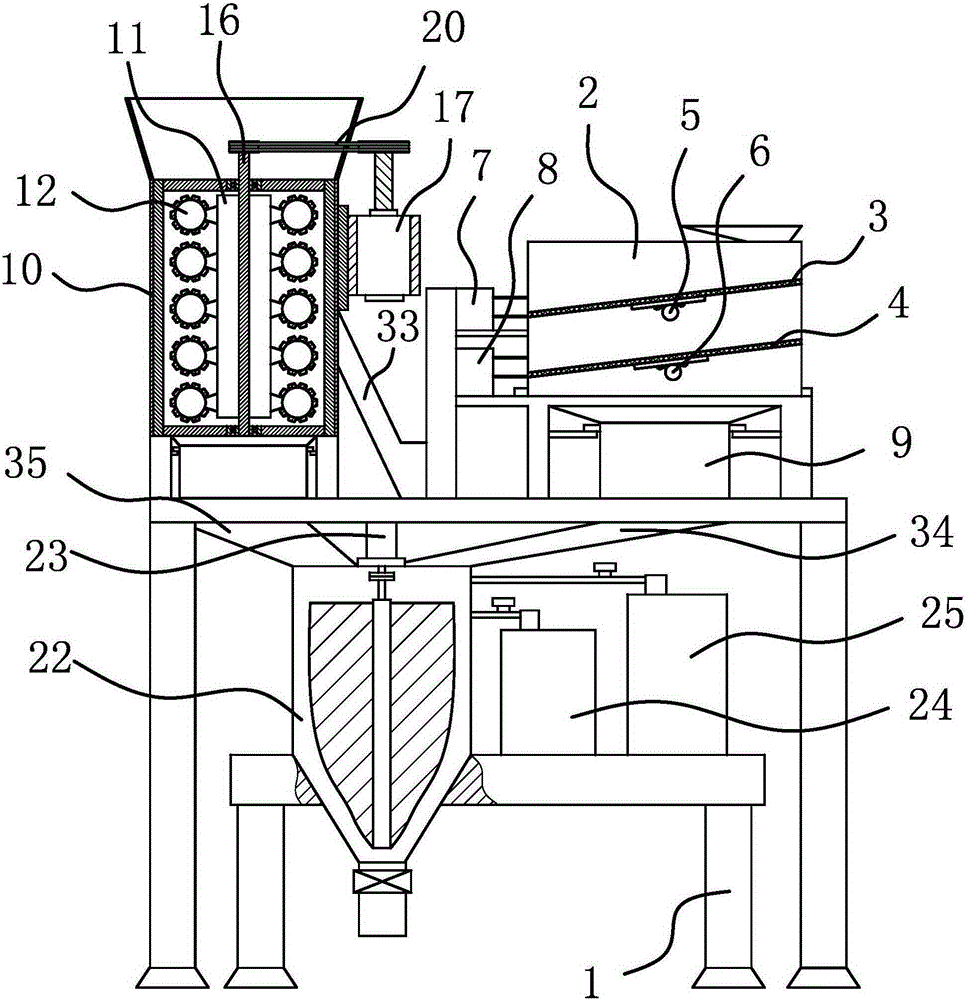

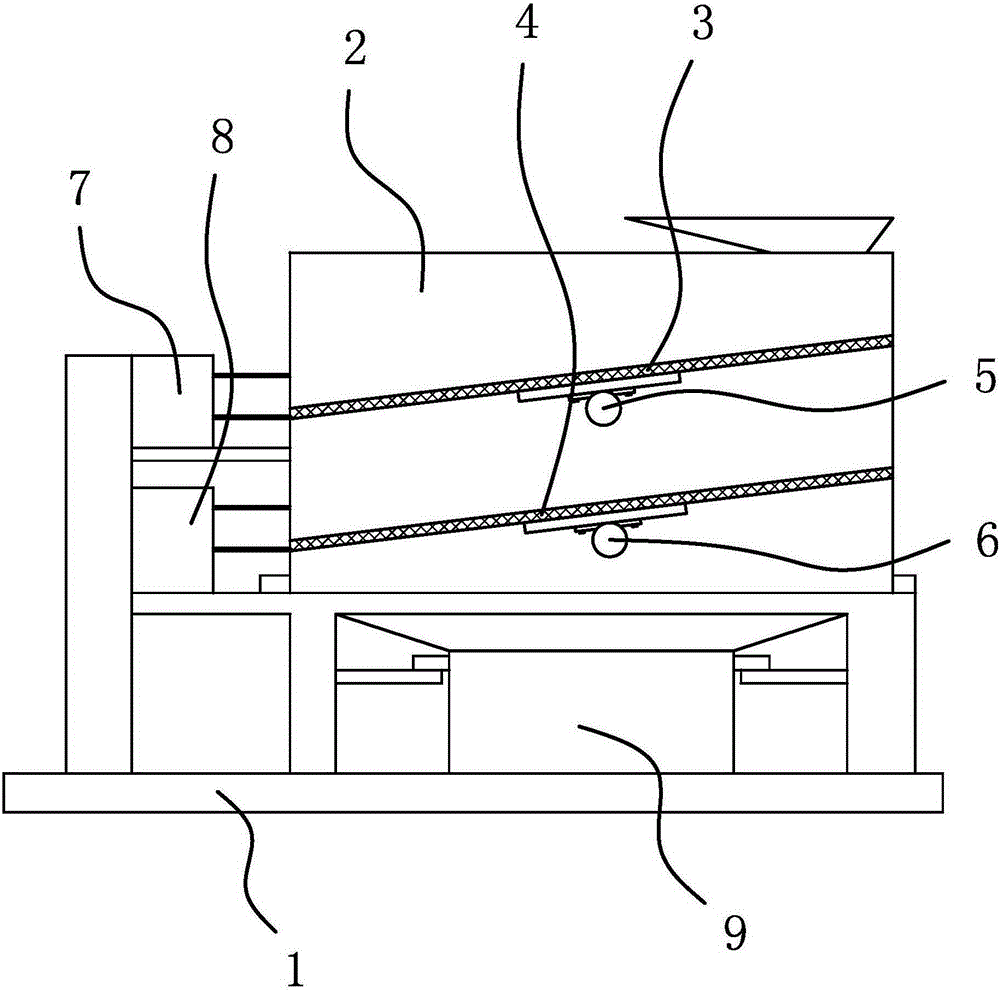

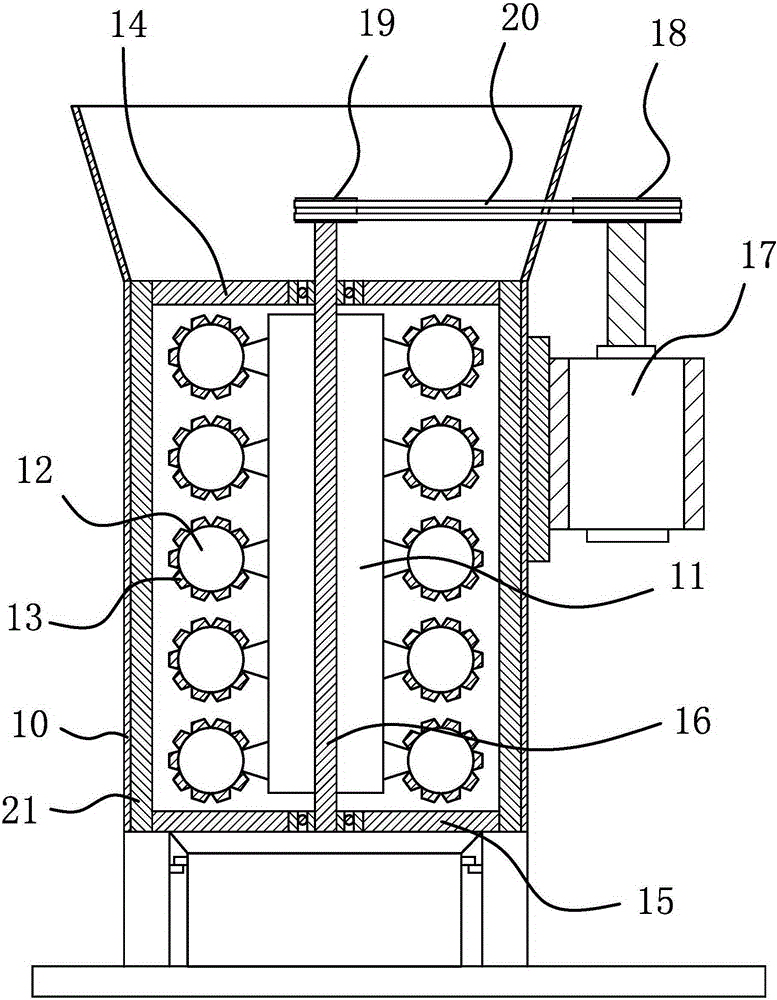

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0036] A method for making a manganese-zinc ferrite material, the manganese-zinc ferrite material includes a main formula of 52-53% by mole percentage of ferric oxide, 19-21% of zinc oxide and 25-30% of manganese oxide , and also includes the auxiliary formula of 400-1000ppm of calcium oxide, 100-600ppm of niobium pentoxide, 100-800ppm of zirconium dioxide, 1000-4000ppm of cobalt trioxide and 100-300ppm of tungsten trioxide in mass percentage.

[0037] In this embodiment, the formula ratio of the manganese zinc ferrite material is: the main formula of ferric oxide 52.5%, zinc oxide 20% and manganese oxide 27% by mole percentage, also includes the mass percentage of calcium oxide 700ppm, five An auxiliary formula of 300ppm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com