Attapulgite-based mineral slow-release fertilizer

A technology of attapulgite and organic fertilizer, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as non-degradable, secondary pollution, soil compaction, etc., achieve low cost, absorb harmful heavy metals, and improve soil quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

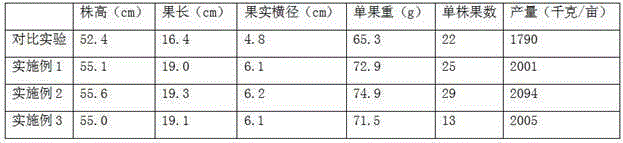

Examples

Embodiment 1

[0046] An attapulgite-based mineral slow-release organic fertilizer, comprising the following preparation steps:

[0047] A. Raw ore crushing

[0048] Crushing the attapulgite ore, the crushing mesh is 30 mesh-60 mesh;

[0049] B. Acidification treatment

[0050] The concentrated sulfuric acid of mass fraction 98% is added in water and is mixed with the sulfuric acid solution of molar concentration 1mol / L, adds sulfuric acid solution in the attapulgite ore broken in step A, and acidification process makes attapulgite clay for 4 hours;

[0051] C. Drying and sieving

[0052] Airing the acidified attapulgite clay, drying to reduce the water content of the attapulgite clay to 15%, then crushing and sieving to obtain attapulgite powder, the mesh size of the attapulgite is 100-150 mesh;

[0053] D. Baking

[0054] Send the screened attapulgite powder into a roasting furnace for roasting, the roasting temperature is controlled at 300°C, and the roasting time is 45 minutes;

[005...

Embodiment 2

[0058] An attapulgite-based mineral slow-release organic fertilizer, comprising the following preparation steps:

[0059] A. Raw ore crushing

[0060] Crushing the attapulgite ore, the crushing mesh is 30 mesh-60 mesh;

[0061] B. Acidification treatment

[0062] The concentrated sulfuric acid of mass fraction 98% is added in water and is mixed with the sulfuric acid solution of molar concentration 2mol / L, adds sulfuric acid solution in the attapulgite ore broken in step A, and acidification process makes attapulgite clay for 4 hours;

[0063] C. Drying and sieving

[0064] Airing the acidified attapulgite clay, drying to reduce the water content of the attapulgite clay to 15%, then crushing and sieving to obtain attapulgite powder, the mesh size of the attapulgite is 100-150 mesh;

[0065] D. Baking

[0066] Send the screened attapulgite powder into a roasting furnace for roasting, the roasting temperature is controlled at 360°C, and the roasting time is 60 minutes;

[0...

Embodiment 3

[0070] An attapulgite-based mineral slow-release organic fertilizer, comprising the following preparation steps:

[0071] A. Raw ore crushing

[0072] Crushing the attapulgite ore, the crushing mesh is 30 mesh-60 mesh;

[0073] B. Acidification treatment

[0074] The concentrated sulfuric acid of mass fraction 98% is added in water and is mixed with the sulfuric acid solution of molar concentration 3mol / L, adds sulfuric acid solution in the attapulgite ore broken in step A, and acidification process makes attapulgite clay for 4 hours;

[0075] C. Drying and sieving

[0076] Airing the acidified attapulgite clay, drying to reduce the water content of the attapulgite clay to 15%, then crushing and sieving to obtain attapulgite powder, the mesh size of the attapulgite is 100-150 mesh;

[0077] D. Baking

[0078] Send the screened attapulgite powder into a roasting furnace for roasting, the roasting temperature is controlled at 360°C, and the roasting time is 120 minutes;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com