Polyamide thermal insulation strip preparation process

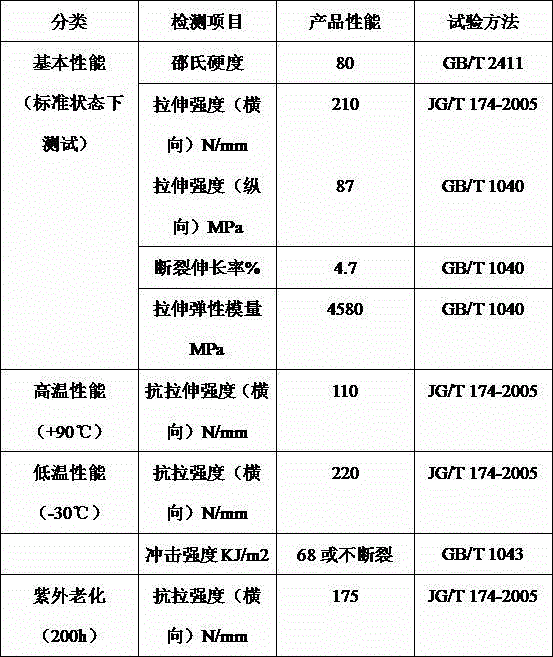

A preparation process and heat insulation strip technology, which is applied in the production process of heat insulation strips, can solve the problems of rough and uneven nylon 66 crystal grains, rough product surface, and difficult to guarantee dimensional accuracy, and achieve good anti-ultraviolet aging performance and overall Good mechanical properties, good heat and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: The preparation of polyamide heat insulation strips, raw material PA66, glass fiber, lubricating dispersant, coupling agent, anti-ultraviolet aging additives are added to a twin-screw granulator in a certain proportion, and the material is modified; In terms of weight percentage, PA6668 parts, 24 parts of glass fiber, 5.2 parts of toughening agent, 1.2 parts of lubricating and dispersing agent, 1.5 parts of coupling agent, 0.1 part of anti-ultraviolet aging agent; the temperature is controlled at 250 ° C; the modified raw material Put it into the barrel for drying, the temperature is controlled above 90°C, and the drying time is 4 hours; the dried raw materials are extruded through the extruder and the corresponding precision mold, and the temperature is controlled above 260°C; the semi-finished product Use a fully automatic laser coding machine to carry out coding marking; pack the marked products according to customer requirements, divide them into straight ...

Embodiment 2

[0026] Embodiment 2: The preparation of polyamide heat-insulating strip, raw material PA66, glass fiber, lubricating dispersant, coupling agent, anti-ultraviolet aging auxiliary agent are added into twin-screw granulator according to certain ratio, carry out material modification; In terms of weight percentage, PA6668 parts, 24 parts of glass fiber, 4.8 parts of toughening agent, 1.5 parts of lubricating and dispersing agent, 1.4 parts of coupling agent, 0.3 part of anti-ultraviolet aging agent; the temperature is controlled at 250 °C; the modified raw material Put it into the barrel for drying, the temperature is controlled above 90°C, and the drying time is 4 hours; the dried raw materials are extruded through the extruder and the corresponding precision mold, and the temperature is controlled above 260°C; the semi-finished product Use a fully automatic laser coding machine to carry out coding marking; pack the marked products according to customer requirements, divide them i...

Embodiment 3

[0027] Embodiment 3: the preparation of polyamide heat-insulating strip, raw material PA66, glass fiber, lubricating dispersant, coupling agent, anti-ultraviolet aging auxiliary agent are added into twin-screw granulator according to certain ratio, carry out material modification; In terms of weight percentage, PA6666 parts, 25 parts of glass fiber, 5.5 parts of toughening agent, 1.3 parts of lubricating and dispersing agent, 1.8 parts of coupling agent, 0.4 part of anti-ultraviolet aging agent; the temperature is controlled at 250 ° C; the modified raw material Put it into the barrel for drying, the temperature is controlled above 90°C, and the drying time is 4 hours; the dried raw materials are extruded through the extruder and the corresponding precision mold, and the temperature is controlled above 260°C; the semi-finished product Use a fully automatic laser coding machine to carry out coding marking; pack the marked products according to customer requirements, divide them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com