Silicone rubber composite material capable of undergoing ceramization and preparation method thereof

A technology for ceramicizing silicone rubber and composite materials, applied in the field of refractory materials, can solve the problems of reducing the self-supporting property and strength of composite materials, decreasing the insulation properties of composite materials, not considering the self-supporting property, etc., so as to facilitate industrial production and improve self-supporting properties. Support and flexural strength, the effect of reducing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

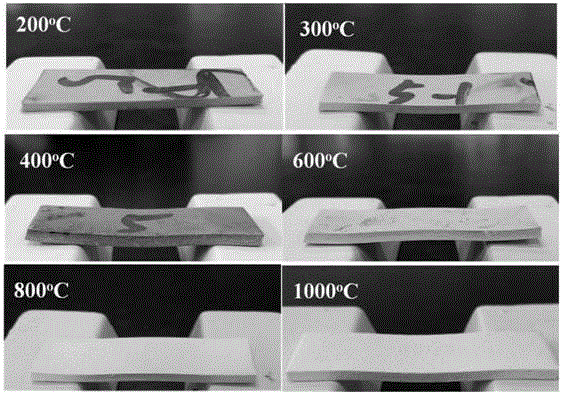

Embodiment 1

[0046] The self-supporting ceramizable silicone rubber composite material (hereinafter referred to as ceramizable silicone rubber composite material) provided in the present embodiment 1 is composed of silicone rubber, aluminum hydroxide, ammonium polyphosphate, clay layer It is composed of structure minerals and vulcanizing agents. The content of each component by weight is: 30 parts of methyl vinyl silicone rubber, 20 parts of aluminum hydroxide, 25 parts of ammonium polyphosphate, 25 parts of mica, and 0.45 parts of dicumyl peroxide.

[0047] Method embodiment 1:

[0048] (1) 30 parts of methyl vinyl silicone rubbers weighed by masticating on an open mill;

[0049] (2) Slowly add the above-mentioned fillers to the masticated silicone rubber: 25 parts of mica, 25 parts of ammonium polyphosphate and 20 parts of aluminum hydroxide, finally add 0.45 part of dicumyl peroxide, and knead evenly;

[0050] (3) The obtained mixed rubber is vulcanized for the first time on a pressur...

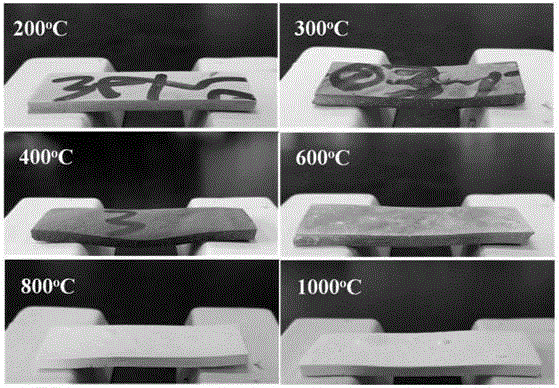

Embodiment 2

[0055] The ceramizable silicone rubber composite material provided in this embodiment is composed of silicone rubber, aluminum hydroxide, ammonium polyphosphate, clay-like layered minerals and a vulcanizing agent. The content of each component is calculated by weight: 30 parts of dimethyl silicone rubber, 20 parts of aluminum hydroxide, 20 parts of ammonium polyphosphate, 30 parts of mica, and 0.45 parts of dicumyl peroxide.

[0056] Method embodiment 2:

[0057] (1) 30 parts of dimethyl silicone rubbers that are weighed by masticating on an open mill;

[0058] (2) Slowly add the above-mentioned fillers to the plasticized silicone rubber: 30 parts of mica, 20 parts of ammonium polyphosphate and 20 parts of aluminum hydroxide, finally add 0.45 parts of dicumyl peroxide, and mix evenly;

[0059] (3) The obtained mixed rubber is vulcanized for the first time on a pressure molding machine, the vulcanization time is 10 minutes, the vulcanization pressure is 16 MPa, and the vulcani...

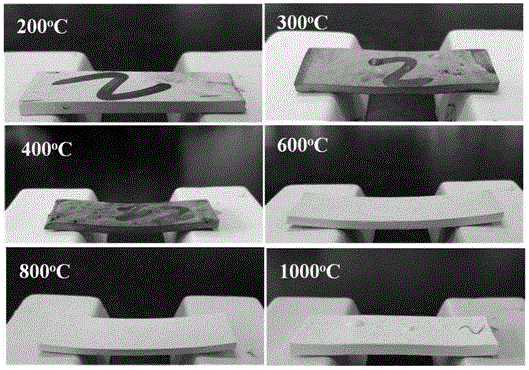

Embodiment 3

[0064] The ceramizable silicone rubber composite material provided in this embodiment is composed of silicone rubber, aluminum hydroxide, ammonium polyphosphate, clay-like layered minerals and a vulcanizing agent. The content of each component is calculated by weight: 25 parts of methyl vinyl phenyl silicone rubber, 15 parts of aluminum hydroxide, 20 parts of ammonium polyphosphate, 25 parts of mica, and 0.3 part of dicumyl peroxide.

[0065] Method embodiment 3:

[0066] (1) 25 parts of methyl vinyl phenyl silicone rubbers that are plasticized on an open mill;

[0067] (2) Slowly add the above-mentioned fillers to the plasticized silicone rubber: 25 parts of mica, 20 parts of ammonium polyphosphate and 15 parts of aluminum hydroxide, finally add 0.3 part of dicumyl peroxide, and mix evenly;

[0068] (3) The obtained mixed rubber is vulcanized for the first time on a pressure molding machine, the vulcanization time is 10 minutes, the vulcanization pressure is 16 MPa, and the vu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com