Heat storage device based on heat utilization of waste hot smoke

A heat storage device and hot flue gas technology, applied in the direction of heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problem that heat can only be discharged into the atmosphere, heat storage devices are less reported, and heat utilization Low efficiency and other problems, to overcome time limitations, improve service life, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

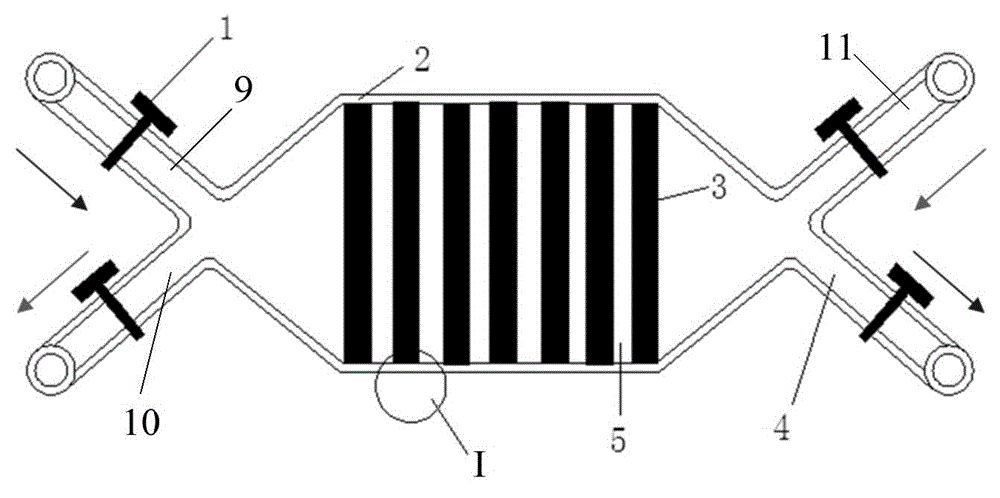

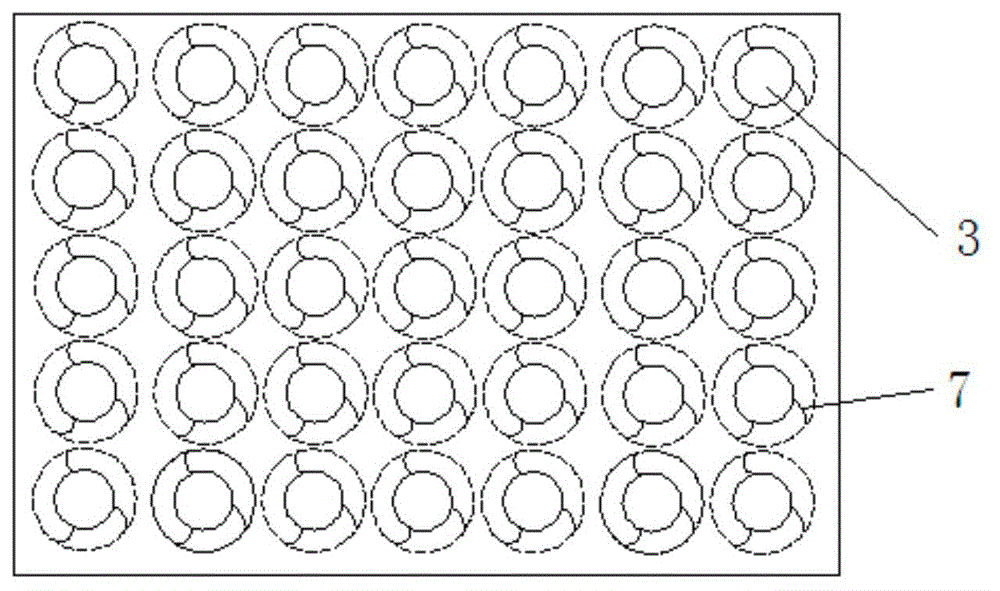

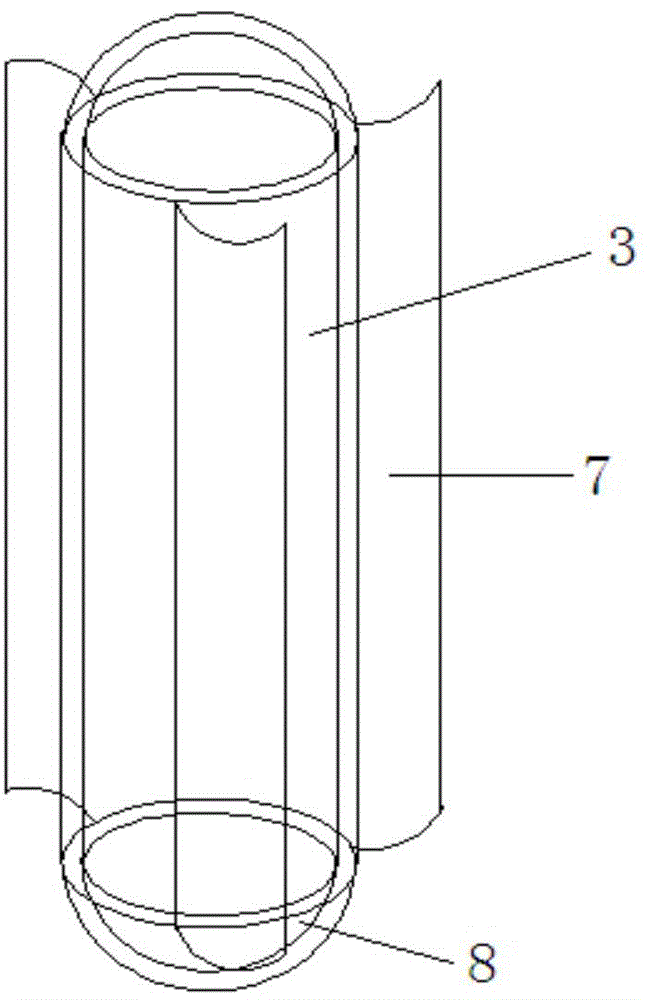

[0033] Such as Figure 1 to Figure 4 As shown, it is a heat storage device based on the heat utilization of waste heat flue gas provided in this embodiment, which includes a heat storage chamber 2, a plurality of heat storage prefabricated parts 3 housed in the heat storage chamber Air intake channel 9, waste heat flue gas exhaust channel 4, cold air intake channel 11 and cold air exhaust channel 10. The waste heat flue gas intake passage 9 and the cold air exhaust passage 10 are connected to one side of the heat storage chamber 2 respectively, and the waste heat flue gas exhaust passage 4 and the cold air intake passage 11 are connected to the other side of the heat storage chamber 2 respectively. connected on one side. A plurality of thermal storage preforms 3 are arranged at intervals, and each thermal storage preform 3 can rotate on its own axis. The gas entering the thermal storage cavity 2 can flow between adjacent thermal storage preforms. The outer wall of the heat ...

Embodiment 2

[0047] This example is roughly the same as Example 1, except that the composition of the heat storage material is: MgCl with a mass fraction of 38.5% 2 , the mass fraction is 61.5% NaCl, the graphene doping amount is MgCl 2 and 1.0% of the total mass of NaCl. Then weigh the heat storage material, mix and grind it until the fineness is about 200 mesh.

[0048] Heat storage performance test:

[0049] The mixed and ground thermal storage material was tested, and the thermal conductivity of the material was 4.2W / (m.k), and the heat of solution was 347kJ / kg. Carry out the heat exchange test on the assembled heat storage device, close the cold air inlet and outlet pipeline valves, and open the waste heat flue gas inlet and outlet pipeline valves. Using hot air at 450°C, the flow rate of the imported waste heat flue gas is 3-5m / s, and the heat exchange is carried out for 1h. Then close the waste heat flue gas inlet and outlet pipe valves, open the cold air intake and exhaust pipe...

Embodiment 3

[0051] This example is roughly the same as Example 1, except that the composition of the heat storage material is: MgCl with a mass fraction of 38.5% 2 , the mass fraction is 61.5% NaCl, the graphene doping amount is MgCl 2 and 1.5% of the total mass of NaCl. Then weigh the heat storage material, mix and grind it until the fineness is about 200 mesh.

[0052] Heat storage performance test:

[0053] The mixed and ground thermal storage material was tested, and the thermal conductivity of the material was 4.6W / (m.k), and the heat of solution was 382kJ / kg. Carry out the heat exchange test on the assembled heat storage device, close the cold air inlet and outlet pipeline valves, and open the waste heat flue gas inlet and outlet pipeline valves. Using hot air at 450°C, the flow rate of the imported waste heat flue gas is 3-5m / s, and the heat exchange is carried out for 1h. Then close the waste heat flue gas inlet and outlet pipe valves, open the cold air intake and exhaust pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com