Method for detecting phthalate plasticizer in inner packing material of medicine

A phthalic acid and detection method technology, which is applied in the field of detection of phthalate plasticizers in drug inner packaging materials, can solve the problems of inability to distinguish plasticizer types, activated carbon adsorption weight gain, poor controllability of results, etc. problems, to achieve the effect of short measurement period, avoiding equipment damage, and accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

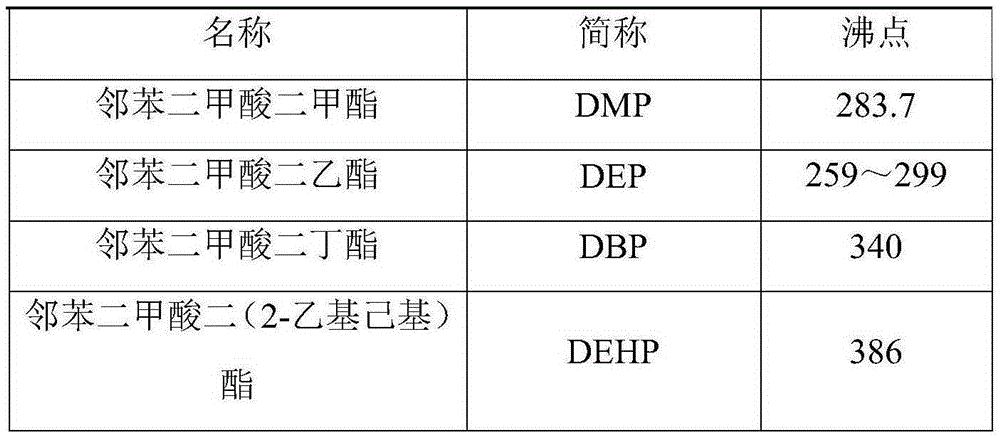

[0026] Determination of plasticizer residues in coating powder:

[0027] Weigh about 0.1g of the coating powder into a 100ml measuring bottle, add an appropriate amount of methanol, heat in a water bath at 80°C and shake continuously for 30 minutes, take it out and let it cool, then dilute to the mark, filter through a filter membrane, and take the subsequent filtrate as the test In addition, weigh about 50mg of DMP, DEP, and DBP in a 50ml measuring bottle, add methanol solvent and dilute to the mark, as the control solution 1; weigh about 50mg of DEHP in a 50ml measuring bottle, add methanol solvent and dilute to Scale, as the control solution 2.

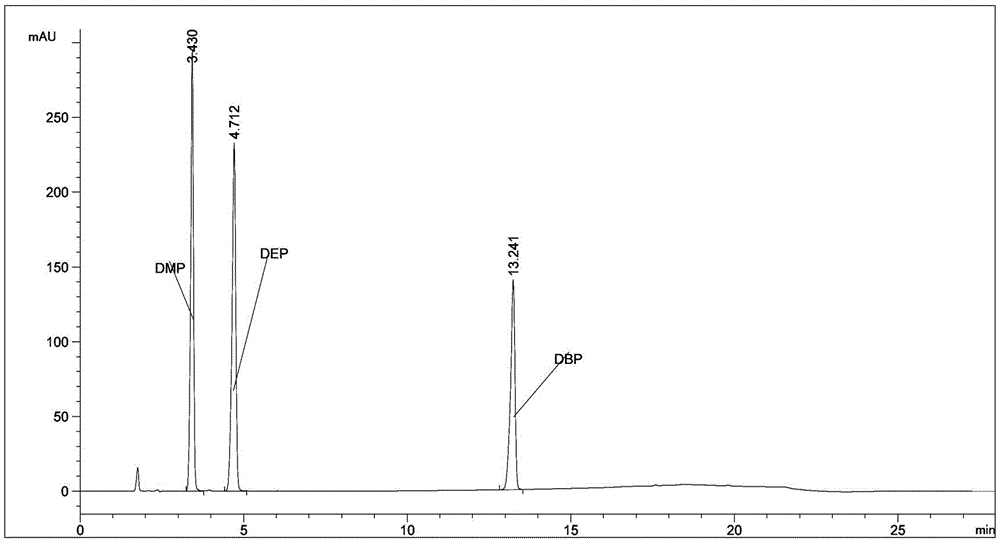

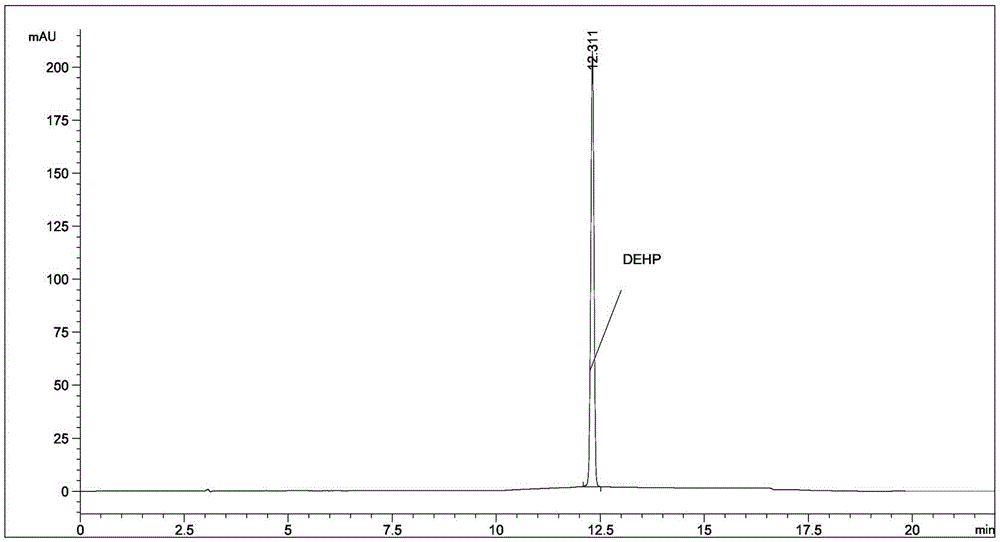

[0028] The chromatographic conditions are as follows: DMP, DEP, DBP, and DEHP all use methanol-water system. Because the polarities of the four plasticizers are too different, two elution methods are used: the first three (DMP, DEP, DBP) Measured under one system, DEHP adopts a strong elution system.

[0029] The detection operat...

Embodiment 2

[0041] Determination of plasticizer residues in granule inner packaging, hard capsules or PVC hard tablets

[0042] Weigh about 5g of granule inner packaging, hard capsule, and PVC hard sheet, cut into pieces, wash with water, dry and place in a 250ml Erlenmeyer flask, add 100ml of methanol, seal, and place in an autoclave (121°C) for treatment 30min, take it out, and take the supernatant as the test solution; weigh about 50mg each of DMP, DEP, and DBP in a 50ml measuring bottle, add methanol solvent and dilute to the mark, as the control solution 1; weigh about 50mg of DEHP in In a 50ml measuring bottle, add methanol solvent and dilute to the mark as the control solution 2.

[0043] The chromatographic conditions are as follows: DMP, DEP, DBP, and DEHP all use methanol-water system. Because the polarities of the four plasticizers are too different, two elution methods are used: the first three (DMP, DEP, DBP) Measured under one system, DEHP adopts a strong elution system.

...

example 3

[0054] Example 3 is to ensure the scientificity and accuracy of the assay method in the actual application process, and comprehensively verify the DMP, DEP, DBP, DEHP residue assay methods in the laboratory, and the verification results are as follows:

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com