Method for determining storage alkalinity of engine coolant

A technology for engine coolant and reserve alkalinity, which is applied in chemical analysis by titration method, can solve the problems of cumbersome daily maintenance of glass electrodes and calomel electrodes, increase maintenance workload, etc., to reduce daily maintenance work, Avoid environmental pollution and health damage problems, the effect of obvious color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] 1) Preparation of 1# coolant sample to be tested:

[0109] Pour the newly purchased cooling liquid sample for reserve alkalinity determination into a 250mL beaker, stir well with a glass rod and set aside;

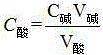

[0110] 2) Preparation of 0.1mol / L hydrochloric acid standard solution:

[0111] Use a 10mL graduated cylinder to measure 9.0mL of concentrated hydrochloric acid, transfer it to a 1000mL volumetric flask, dilute it with ultrapure water to the scale of the 1000mL volumetric flask, and shake well to be labeled;

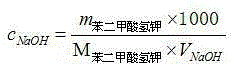

[0112] 3) Preparation of 0.1mol / L sodium hydroxide standard solution:

[0113] On an electronic balance, weigh 2.0 g of solid sodium hydroxide in a 50 mL beaker, add ultrapure water to dissolve it completely, then transfer it to a 500 mL volumetric flask, then dilute to the scale of the 500 mL volumetric flask with the same ultrapure water, shake evenly waiting for the mark;

[0114] 4) Preparation of indicator solution:

[0115] In the process of measurin...

Embodiment 2

[0155] For the determination of the reserve alkalinity in the 2# cooling liquid sample to be tested, the detection steps are consistent with steps 1) to 8) in Example 1. Among them, the detection data of the alkalinity content of the 2# cooling liquid samples to be tested are shown in Table 2.

[0156] Table 22# test cooling liquid sample storage alkalinity measurement data

[0157]

[0158]

Embodiment 3

[0160] For the determination of the reserve alkalinity in the 3# cooling liquid sample to be tested, the detection steps are consistent with steps 1) to 8) in Example 1. Among them, the detection data of the alkalinity content of the 3# cooling liquid sample reserve is shown in Table 3.

[0161] Table 33# test cooling liquid sample storage alkalinity measurement data

[0162]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com