Silicon nitride rolling element with excellent fatigue performances and manufacturing method thereof

A technology for rolling elements and manufacturing methods, which is applied in the field of ceramic materials and can solve problems such as the inability to change the content and distribution of grain boundary phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

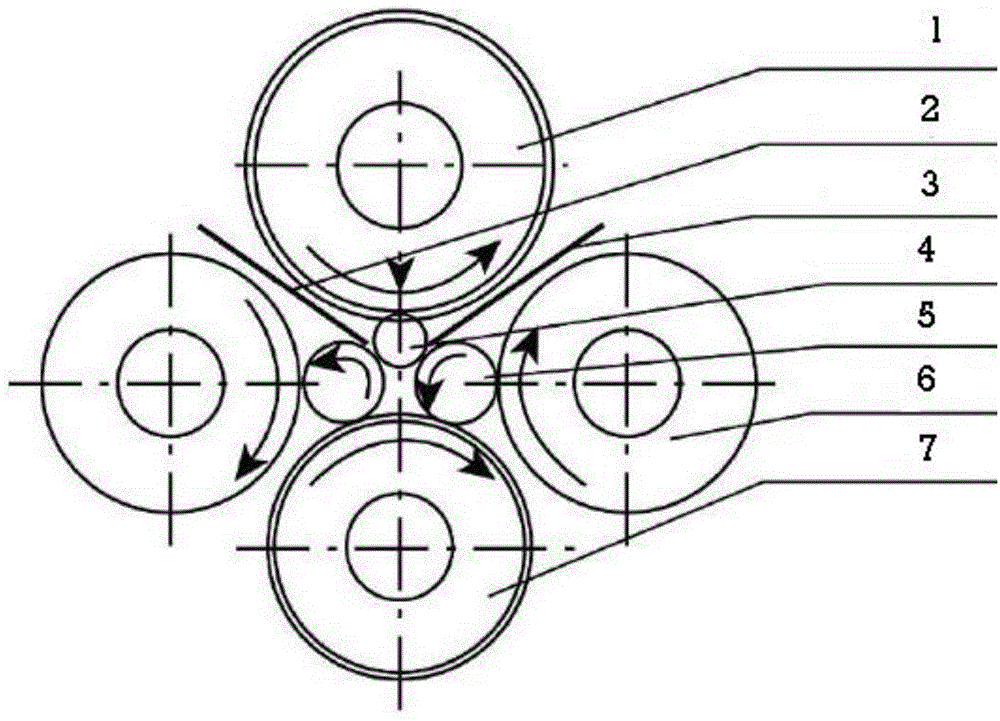

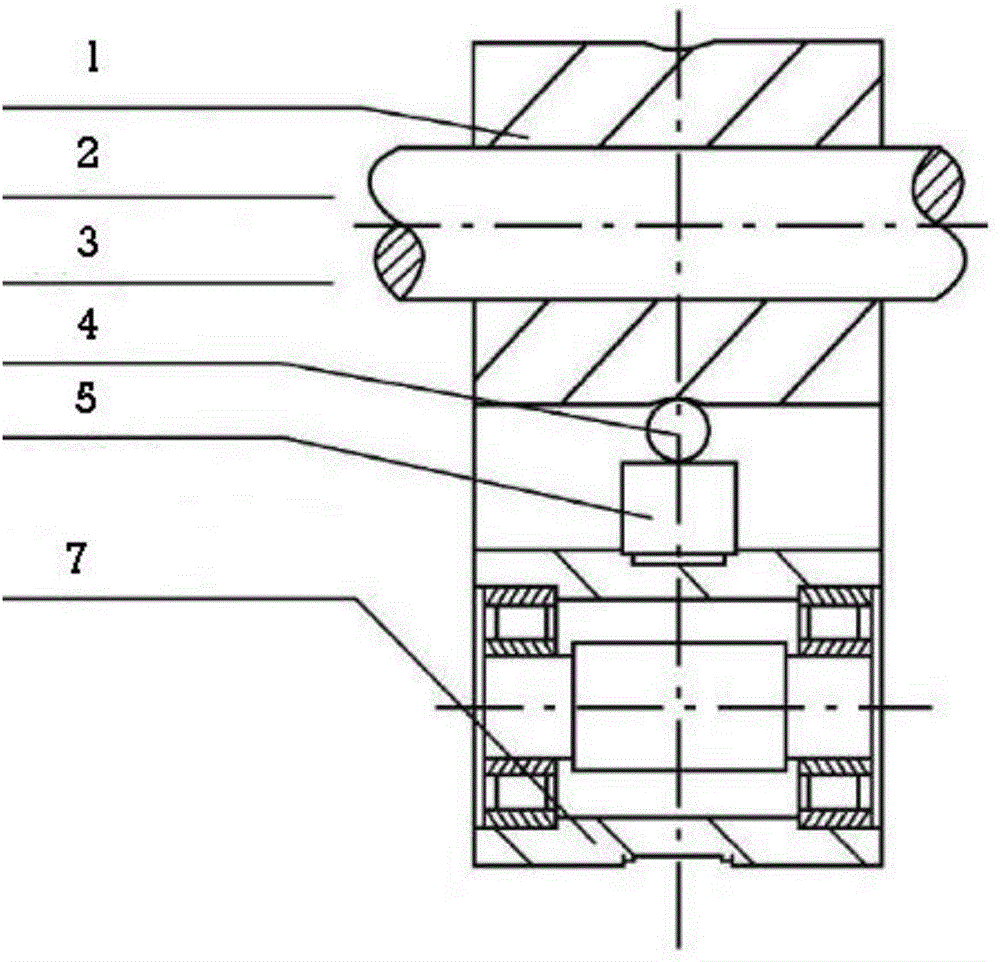

[0015] Embodiment 1 A kind of Si with superior fatigue performance 3 N 4 rolling element

[0016] Its manufacturing method includes the following process steps:

[0017] Mainly containing α-Si 3 N 4 Si 3 N 4 Powder is used as the raw material, and about 10% of the mass fraction of rare earth element oxides, Al oxides and nitrides are added to it, mixed evenly by ball mill wet mixing, and the raw material mixture is dry-pressed into a green body, which is cooled and isostatic. After pressing to make it more dense, carry out air pressure sintering, that is, place the green body in 1-10MPa N 2 Sintering is carried out in the temperature range of 1700-1900°C in the atmosphere, and the holding time is 1-2h. After the sintering is completed, the N 2 Or Si at a temperature of 1700-1900°C in an Ar atmosphere 3 N 4 The sintered body is subjected to HIP treatment, and then heat treatment, the Si 3 N 4 The sintered body is placed in N 2 In the atmosphere, keep it warm at 1300...

Embodiment 2

[0019] Embodiment 2 A kind of Si with superior fatigue performance 3 N 4 rolling element

[0020] Si with sintering aid added 3 N 4 The powder is mixed evenly, and the raw material mixture is formed into a biscuit by dry pressing, and after being further compacted by cold isostatic pressing, the gas pressure sintering is carried out, that is, the biscuit is placed in a 1-10MPa N 2 Sintering is carried out in the temperature range of 1700-1900°C in the atmosphere, and the holding time is 1-2h. After the sintering is completed, the N 2 Or Si at a temperature of 1700-1900°C in an Ar atmosphere 3 N 4 The sintered body is subjected to HIP treatment, and then heat treatment, the Si 3 N 4 The sintered body is placed in vacuum and kept at 1300-1500°C for 10-30h, so that Si 3 N 4 The grain boundary phase (glass phase) in the sintered body is further absorbed by the Sialon phase contained in the sintered body. At the same time, the grain boundary phase is crystallized to improv...

Embodiment 3

[0022] Embodiment 3 A kind of Si with superior fatigue performance 3 N 4 rolling element

[0023] Si with sintering aid added 3 N 4 The powder is mixed evenly, and the raw material mixture is formed into a biscuit by dry pressing, and after being further compacted by cold isostatic pressing, the gas pressure sintering is carried out, that is, the biscuit is placed in a 1-10MPa N 2 Sintering is carried out in the temperature range of 1700-1900°C in the atmosphere, and the holding time is 1-2h. After the sintering is completed, heat treatment is carried out, and the Si 3 N 4 The sintered body is placed in N 2 In the atmosphere, keep it warm at 1300~1500℃ for 10~30h, so that Si 3 N 4 The grain boundary phase (glass phase) in the sintered body is further absorbed by the Sialon phase contained in the sintered body. At the same time, the grain boundary phase is crystallized to improve its strength and its bonding force with the matrix material. Finally, machining is performed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com