Polyether de-emulsifier and W/O-type crude oil emulsion demulsification dehydration method using the same

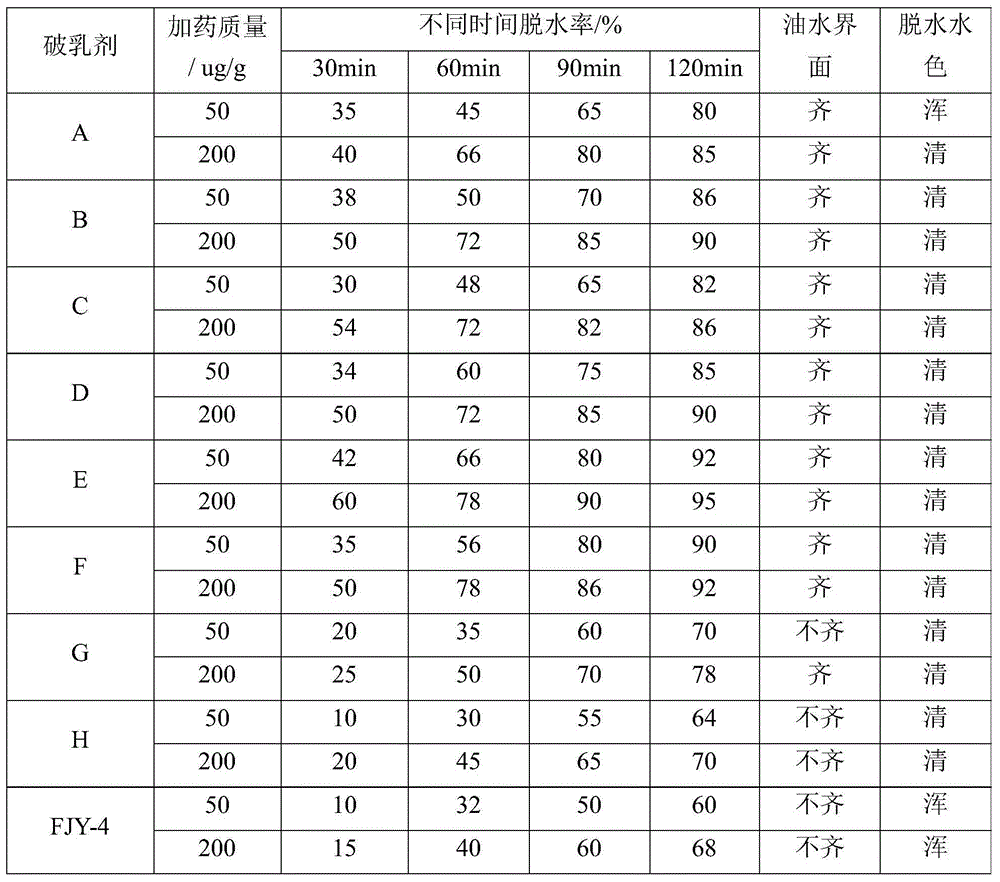

A polyether demulsifier and demulsifier technology are applied in the fields of demulsification and dehydration and polyether demulsifier, which can solve the difficulty of synthesizing polyamide-amine type macromolecules, limit the synthesis and application of hyperbranched polyether, and polyether demulsification. The problem of unsatisfactory effect, etc., achieves good demulsification performance, is easy to industrialize large-scale production and application, and avoids the effect of lengthy synthesis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This example was used to prepare the demulsifiers of the present invention.

[0047] (1) 7.0 grams (2.5 mmol) of 1.5 generation polyamide-amine macromolecules (terminated as ester groups, purchased from Weihai Chenyuan Molecular New Materials Co., Ltd., 1.5 generation PAMAM-COOCH 3 ) was dissolved in 10 milliliters of methanol, and was added dropwise to 20.7 grams (40 mmol) of 0-generation polyamide-amine macromolecules (terminal groups were amino groups, purchased from Weihai Chenyuan Molecular New Materials Co., Ltd., 0-generation PAMAM-NH 2 ) in 200 ml of methanol solution, heated to reflux for 4 hours under nitrogen protection, and removed the solvent under reduced pressure.

[0048] (2) Add 2g of the product of step (1) and 1g of catalyst KOH into the autoclave, fully purge the pipeline and the reactor with nitrogen for 3 times, stir and slowly add 114g of propylene oxide dropwise when the temperature is raised to 120°C, Control the temperature at 120°C-150°C and ...

Embodiment 2

[0050] This example was used to prepare the demulsifiers of the present invention.

[0051] (1) Dissolve 14.4 g (5 mmol) of 1.5 generation polyamide-amine type macromolecule (end group is ester group, purchased from Weihai Chenyuan Molecular New Material Co., Ltd.) in 25 ml of methanol, and add dropwise to 57.2 g (40 millimoles) in the methanol solution (200 milliliters) of 1.0 generation polyamide-amine type macromolecules (terminated as amine group, purchased from Weihai Chenyuan Molecular New Material Co., Ltd.), heated and refluxed under nitrogen protection for 6 hours, reduced The solvent was removed under pressure.

[0052] (2) Add 2g of the product of step (1) and 1g of catalyst NaOH into the autoclave, fully purge the pipeline and the reactor with nitrogen for 3 times, stir and slowly add 145g of propylene oxide dropwise when the temperature is raised to 120°C, Control the temperature at 120°C-150°C and the pressure of 0.1MPa-0.4MPa until the reaction is complete, add...

Embodiment 3

[0054] This example was used to prepare the demulsifiers of the present invention.

[0055] (1) 14.4 grams (5 mmol) of 1.5 generation polyamide-amine type macromolecules (end groups are ester groups, purchased from Weihai Chenyuan Molecular New Materials Co., Ltd., dissolved in 25 milliliters of methanol, added dropwise to 57.2 grams (40 mmol) 1.0 generation polyamide-amine type macromolecule (terminal is amine group, purchased from Weihai Chenyuan Molecular New Material Co., Ltd.), in 200 ml of methanol solution, heated to reflux for 6 hours under nitrogen protection, and decompressed Solvent was removed.

[0056] (2) Add 10g of the product of step (1) and 1g of catalyst sodium ethoxide into the autoclave, fully purge the pipeline and the autoclave with nitrogen for 3 times, stir and slowly add 168g of propylene oxide dropwise when the temperature is raised to 120°C , control the temperature at 120°C-150°C, and the pressure at 0.1MPa-0.4MPa until the reaction is complete, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com