Polyglycerol polyether polyol and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

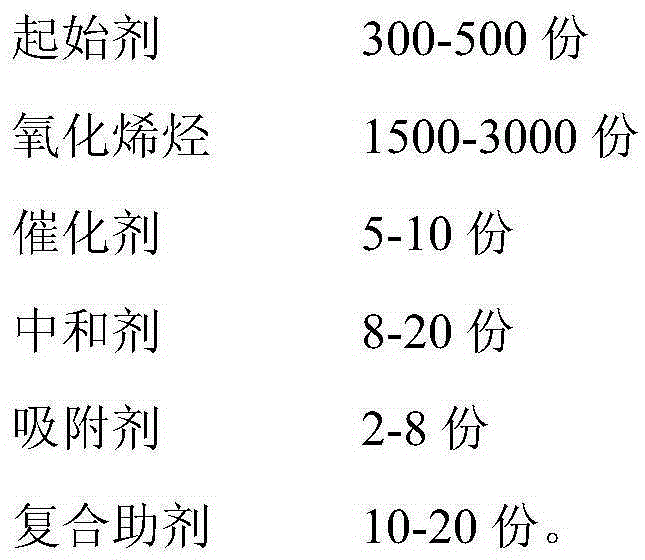

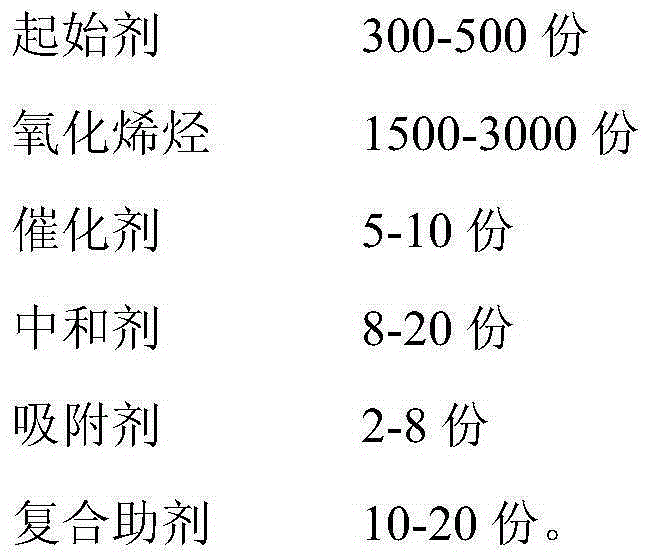

Method used

Image

Examples

Embodiment 1

[0026] In a 5L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 362 g of tetrapolyglycerol, 5.5 g of potassium hydroxide, and replace with nitrogen for 5 times After adding 135g of ethylene oxide, heat up and stir, and react at 80-85°C with a pressure of 0.25MPa for 2 hours. Afterwards, the temperature was raised to 115°C, and the pressure was controlled at 0.25MPa. The remaining 2013g of ethylene oxide was divided into 10 batches and added successively. After the addition was completed, the reaction was carried out, and the post-aging was performed for 4 hours. After that, a phosphoric acid aqueous solution was added to neutralize the reaction at 100°C. For 1 hour, add 1.5g of magnesium silicate and 1.5g of aluminum silicate, stir well for 20 minutes, dehydrate and filter under vacuum, add antioxidant Chic3338: 1.5g, ChicF96: 3.0g to the obtained polyether...

Embodiment 2

[0028] In a 5L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 100 g of triglycerol, 150 g of tetraglycerol, 110 g of pentaglycerol, Potassium hydroxide 6.5g, nitrogen replacement 3 times, add 190g propylene oxide, heat up and stir, react at 80-85°C, pressure 0.2MPa for 2 hours. Afterwards, the temperature was raised to 110°C, the pressure was controlled at 0.3MPa, and the remaining 2650g of propylene oxide was divided into 8 batches and added successively. After the addition was completed, the reaction was carried out, and after aging for 5 hours, the phosphoric acid aqueous solution neutralizing agent was added to carry out the neutralization reaction at 95°C. Hours, add 3.3g of magnesium silicate and 2.3g of aluminum silicate, fully stir for 20 minutes, dehydrate and filter under vacuum, add antioxidant Chic3338: 5.0g, ChicF96: 2.5g to the obtained poly...

Embodiment 3

[0030] In a 5L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 350 g of tetraglycerol, 120 g of pentaglycerol, and 8 g of potassium hydroxide, Nitrogen was replaced 4 times, 90g of butylene oxide was added, heated and stirred, and reacted at 80-85°C and pressure 0.3MPa for 2 hours. Afterwards, the temperature was raised to 115°C, and the pressure was controlled at 0.3MPa. The remaining 1558g of propylene oxide was divided into 9 batches and added successively. After the addition was completed, the reaction was carried out, and the post-aging was performed for 6 hours. After that, a phosphoric acid aqueous solution was added to neutralize the reaction at 95°C. 1 hour, add 3g of magnesium silicate and 4.5g of aluminum silicate, stir thoroughly for 20 minutes, dehydrate and filter under vacuum, add antioxidant Chic3338: 3.0g, ChicF96: 3.0g to the obtained pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com