Weaving method of woven spacer fabric structural antenna

A technology of weaving spacer fabrics and spacer fabrics, which is applied in the directions of antenna grounding devices, radiating element structures, antenna supports/mounting devices, etc., which can solve problems such as collapse, delamination, and antenna system failure, and achieve light weight and high gain Good performance, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

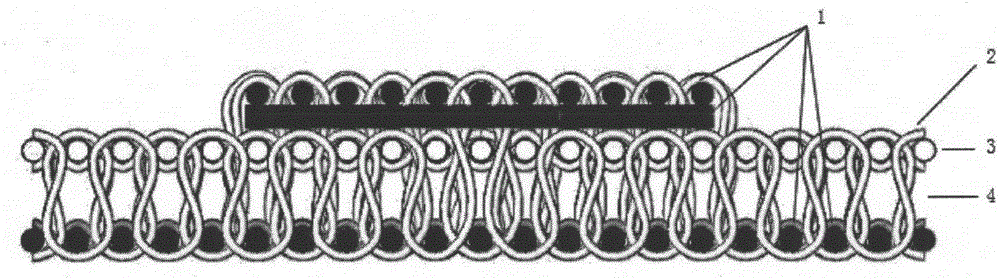

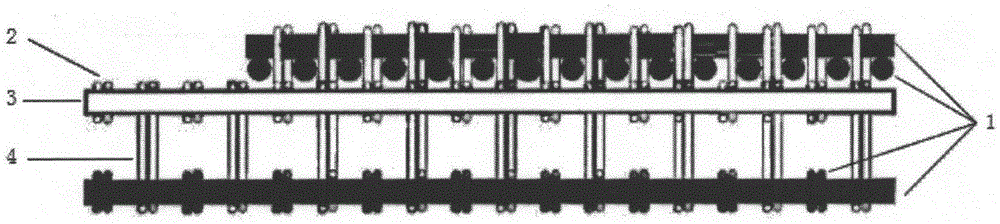

[0042] Embodiment 1: E-glass fiber spacer composite material microstrip antenna

[0043] (1) E glass fiber provided by Zhejiang Jushi Group is selected as the fiber composite reinforcement. The warp yarn 3 fineness of the glass fiber is 1102tex, the weft yarn 2 fineness is 600tex, and the spacer yarn 4 fineness is 370tex. The conductive yarn 1 used in this example is a copper stranded wire provided by Wuxi Liz Precision Electrical Wire Co., Ltd., wherein the diameter of the warp yarn 3 is 0.3 mm, and the diameter of the weft yarn 2 is 0.5 mm. JL-235 type resin and JH-242 type curing agent provided by Changshu Jiahua Co., Ltd. are selected. The resin and curing agent are uniformly mixed according to the ratio of 3:1 during molding, and the curing temperature is 50°C-70°C.

[0044] (2) The working frequency of the antenna designed in this embodiment is 1.5 GHz, the thickness of the prepared spacer glass fiber composite material is 5 mm, and its dielectric constant εr=2.5, which ...

Embodiment 2

[0047] Example 2: Microstrip antenna made of low-dielectric glass fiber spacer composite material

[0048] (1) The low dielectric loss performance fiber selected in this embodiment is E glass fiber, and its fineness is 300tex. The conductive yarn 1, resin and curing agent selected are the same as those in Embodiment 1.

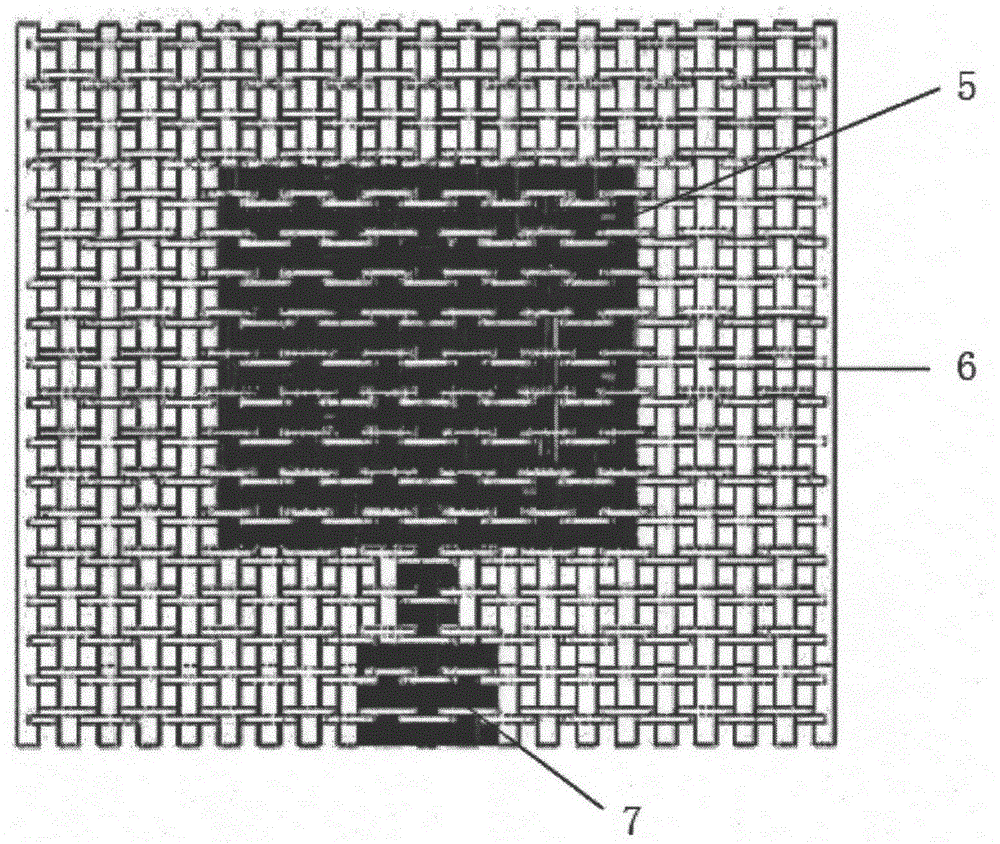

[0049] (2) The operating frequency of the antenna designed in this embodiment is 1.5 GHz, and the thickness of the prepared spacer glass fiber composite material is 2 mm, and its dielectric constant εr=2, which can be calculated according to empirical formulas 1-1 to 1-8 to obtain a single Dimension parameters of radiating element 5 microstrip antenna, such as Figure 4shown. Where W and L are the width and length of the radiating element 5 respectively, WG and LG are the width and length of the finished conformal carrying microstrip antenna, FL is the length of the microstrip line 7 , and FD is the width of the microstrip line 7 .

[0050] (3) Weaving a mic...

Embodiment 3

[0053] Embodiment 3: Microstrip antenna with single radiating element 5 based on aramid spacer fabric

[0054] (1) Aramid fiber is selected as the fiber composite reinforcement with a fineness of 167tex; nylon silver-plated yarn is selected as the conductive yarn 1 with a fineness of 20tex.

[0055] (2) The operating frequency of the single radiating element 5 microstrip antenna designed in this embodiment is 2.4GHz, and the density and thickness of the spaced aramid fiber composite material are the same as in Embodiment 1, and its dielectric constant εr=1.8, according to experience Formulas 1-1 to 1-8 can be used to calculate the size parameters of the single radiating element 5 microstrip antenna, such as Figure 4 shown. Where W and L are the width and length of the radiating element 5 respectively, WG and LG are the width and length of the finished conformal carrying microstrip antenna, FL is the length of the microstrip line 7 , and FD is the width of the microstrip line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com