Method for preparing nano CaCu3Ti4O12 ceramic material with giant dielectric constant

A technology of giant dielectric constant and ceramic materials, which is applied in the field of electronic ceramic preparation and technical application, can solve the problem of low dielectric constant of nano-copper calcium titanate, and achieve the advantages of promoting and popularizing, overcoming the increase, and shortening the time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

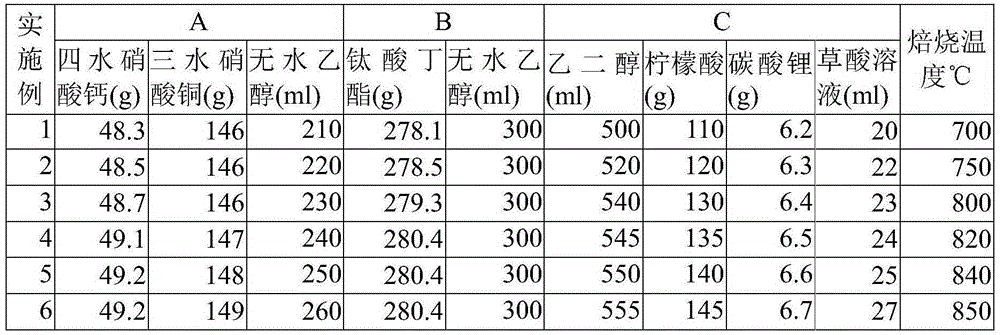

Embodiment 1

[0021] At room temperature as CaCu 3 Ti 4 o 12 The stoichiometric ratio of the substance weighs 48.3gCa(NO 3 ) 2 4H 2 O and 146gCu(NO 3 ) 2 ·3H 2 O is dissolved in a beaker with 210mL of absolute ethanol, stirred evenly (it can be heated until completely dissolved), and made into liquid A; 278.1g of butyl titanate (C 16 h 36 o 4 Ti) was dissolved in a beaker with 300mL of absolute ethanol, stirred evenly to make liquid B; 500mL of ethylene glycol, 110g of citric acid, 6.2g of lithium carbonate, 20mL of oxalic acid aqueous solution (oxalic acid concentration 0.5mol / L) were evenly mixed It is liquid C. Slowly drop solution B into solution A and stir. At the same time, the temperature is raised rapidly and then refluxed for reaction. The reaction temperature is controlled at 80° C., the pH value is adjusted to 5.0-6.0 with acetic acid, and the reaction time is 1 h. Then slowly drop liquid C into the mixed liquid A and B, adjust the pH value to 3.0-4.0 with acetic acid,...

Embodiment 2

[0023] Weigh 48.5g Ca(NO 3 ) 2 4H 2 O and 146gCu(NO 3 ) 2 ·3H 2O was dissolved in a beaker with 220mL of absolute ethanol, stirred evenly to make liquid A; 278.5g of butyl titanate was dissolved in a beaker with 300mL of absolute ethanol, stirred evenly to make liquid B; 520mL Ethylene glycol, 120 g of citric acid, 6.3 g of lithium carbonate, and 22 mL of oxalic acid aqueous solution (0.5 mol / L) were uniformly mixed into liquid C. Slowly drop solution B into solution A and stir, and at the same time rapidly raise the temperature and then reflux reaction, control the reaction temperature to 85°C, adjust the pH value to 5.0-6.0 with acetic acid, and the reaction time is 1h. Then slowly drop liquid C into the mixed liquid A and B, adjust the pH value to 3.0-4.0 with acetic acid, control the temperature at 80°C, and continue stirring for 2 hours after the dropwise addition is completed. Wash the product with water, filter, put it in a drying oven, dry it at 150°C, take it ou...

Embodiment 3

[0025] Weigh 48.7g Ca(NO 3 ) 2 4H 2 O and 146gCu(NO 3 ) 2 ·3H 2 O was dissolved in a beaker with 230mL of absolute ethanol, and stirred evenly to make liquid A; 279.3g of butyl titanate was dissolved in a beaker with 300mL of absolute ethanol, stirred evenly, to make liquid B; 540mL Ethylene glycol, 130 g of citric acid, 6.4 g of lithium carbonate, and 23 mL of oxalic acid aqueous solution (0.5 mol / L) were uniformly mixed into liquid C. Slowly drop solution B into solution A and stir. At the same time, the temperature is raised rapidly and then refluxed for reaction. The reaction temperature range is controlled at 90°C. The pH value is adjusted to 5.0-6.0 with acetic acid, and the reaction time is 1h. Then slowly drop liquid C into the mixed liquid A and B, adjust the pH value to 3.0-4.0 with acetic acid, control the temperature at 80°C, and continue stirring for 2 hours after the dropwise addition is completed. Wash the product with water, filter it, put it in a drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com