Novel method for preparing perovskite thin film

A technology of perovskite and a new method, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve problems such as limiting the large-scale preparation of perovskite thin films, increasing the cost of perovskite, and limiting selection, etc., to achieve Good for separation and transmission, fewer defects, and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

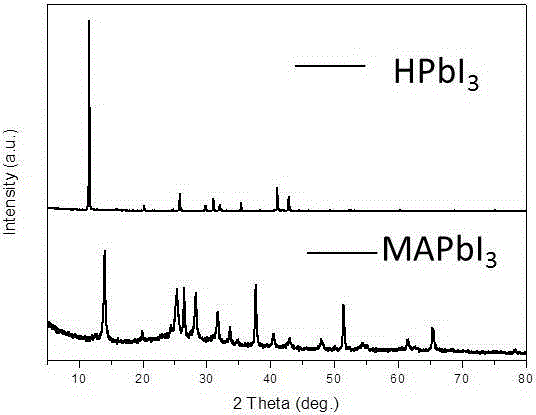

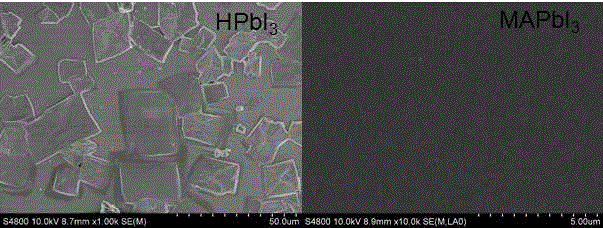

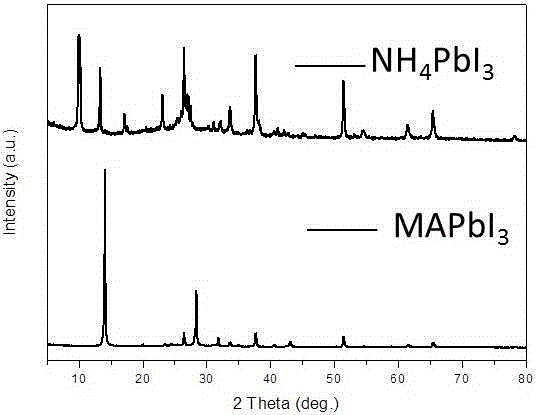

[0023] First, TiO was prepared by sol-gel method 2 Colloid, spin-coated on the cleaned FTO glass, then 500 o C heat treatment for 30min to obtain dense TiO 2 film. Spin-coating TiO on dense thin films 2 Slurry, TiO 2 particle size ~20nm, and then a further 500 o C heat treatment for 30min to obtain TiO 2 mesoporous film. Second, the HPbI 3 The crystals were prepared as a 50% solution by weight and then spin-coated on mesoporous TiO 2 film, heated to 100 o C, 10min, volatilize the solvent, then the prepared HPbI 3 The film was fumigated with methylamine gas for 4s to obtain a dense methylamine-lead-iodide perovskite film with good crystallinity. Finally, the hole transport layer spiro was spin-coated on the perovskite layer, and the silver electrode was vapor-deposited to assemble a solar cell device.

[0024] Characterize the perovskite film obtained in this embodiment and the solar cell prepared from this film, such as figure 1 pre-HPbI 3 membrane and treated CH3...

Embodiment 2

[0026] First, TiO was prepared by sol-gel method 2 Colloid, spin-coated on the cleaned FTO glass, then 500 o C heat treatment for 30min to obtain dense TiO 2 film. Spin-coating TiO on dense thin films 2 Slurry, TiO 2 particle size ~20nm, and then a further 500 o C heat treatment for 30min to obtain TiO 2 mesoporous film. Second, the HPbI 3 The crystals were prepared as a 50% solution by weight and then spin-coated on mesoporous TiO 2 film, heated to 100 o C, 10min, volatilize the solvent, then in the prepared HPbI 3 Drop 0.1mL of 1mol / L methylamine chlorobenzene solution on the film, and then rotate it at 3000r / min for 40s to obtain a dense methylamine lead iodide perovskite film with good crystallinity. Finally, the hole transport layer spiro was spin-coated on the perovskite layer, and the silver electrode was vapor-deposited to assemble a solar cell device. The resulting cell efficiency was 15.8%.

Embodiment 3

[0028] First, TiO was prepared by sol-gel method 2 Colloid, spin-coated on the cleaned FTO glass, then 500 o C heat treatment for 30min to obtain dense TiO 2 film. Second, the HPbI 3 The crystals were prepared as a 50% solution by weight and then spin-coated on dense TiO 2 film, heated to 100 o C, 10min, volatilize the solvent, then the prepared HPbI 3 The film was fumigated with ethylamine gas for 4s to obtain a dense yellow-phase ethylamine-lead-iodide perovskite film with good crystallinity. Finally, the hole transport layer spiro was spin-coated on the perovskite layer, and the silver electrode was vapor-deposited to assemble a solar cell device. The resulting cell efficiency was 2.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com