A kind of preparation method and application of highly conductive flake silver powder

A technology of flaky silver powder and high conductivity, which is applied in the field of preparation of high conductive flaky silver powder, can solve the problems of wide powder size distribution, low tap density, insufficient flaky degree, etc., and achieve particle size distribution Narrow, increased dosage, good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

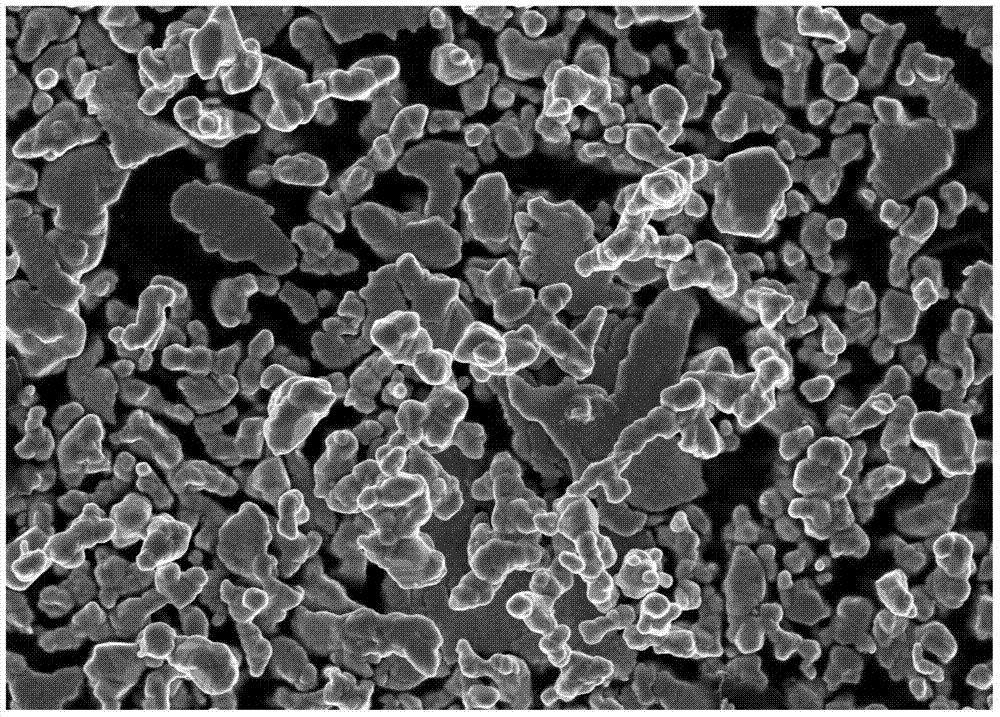

Embodiment 1

[0037] 1. Requirements: The silver content of the spherical or quasi-spherical ultrafine silver powder is 99.95-99.99%, and the particle size is 40-80 nanometers. The particle size of the conductive graphite powder is 130-180 microns, and the carbon content is 99.98-99.99%. The diameters of the zirconia balls are mm and mm.

[0038] 2. Weigh 1,000 grams of spherical silver powder, add 8.16 grams of conductive graphite powder, 8.16 grams of terpineol ball milling aid, and 1,024.49 grams of isopropanol ball milling solvent, and grind it thoroughly to make it evenly mixed. Add 8000 grams of mass ratio as The zirconia balls were ball milled in a horizontal ball mill with a ball milling speed of 60 rpm and a ball milling time of 20 hours. The ball-milled product was repeatedly washed 5 times with absolute ethanol, dried in vacuum at 45° C. for 9 hours, and finally pulverized. The flaky silver powder with D50 of 1.0 micron, D90 of 1.7 micron, Dmax of less than 4 microns, tap ...

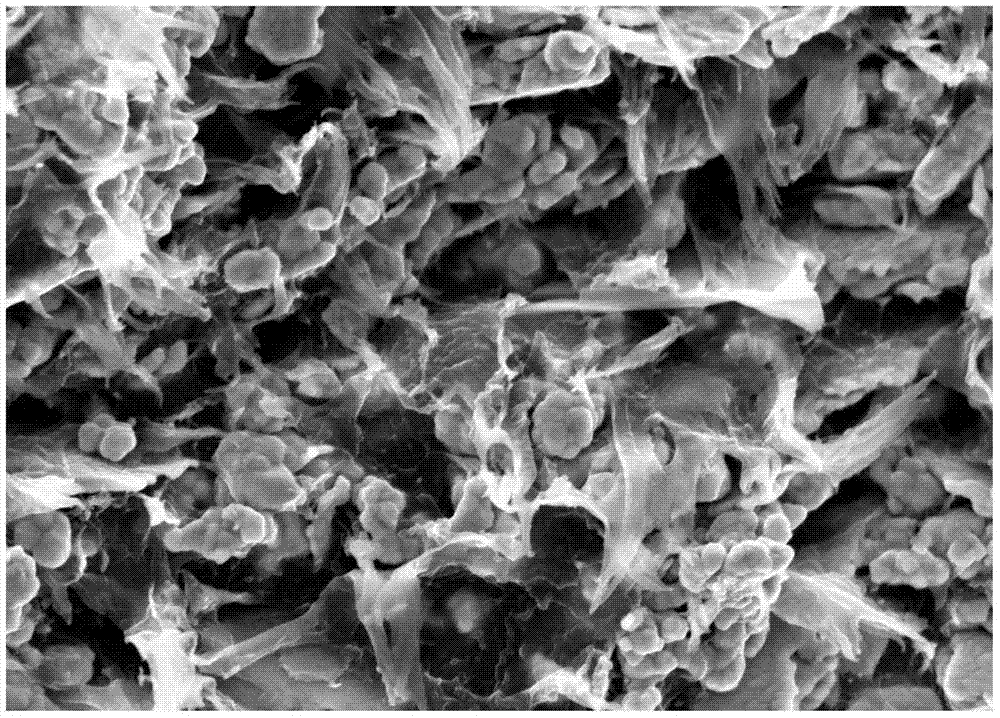

Embodiment 2

[0041] 1. Requirements: The silver content of the spherical or quasi-spherical ultrafine silver powder is 99.95-99.99%, and the particle size is 70-120 nanometers. The particle size of the modified conductive expanded graphite powder is 80-120 microns, and the carbon content is 99.98-99.99%. The diameter of the zirconia ball is mm.

[0042] 2. Weigh 1000 grams of spherical silver powder, add 12.14 grams of modified conductive expanded graphite powder, 4.05 grams of polyvinyl alcohol ball milling aid, and 1008.10 grams of n-butanol ball milling solvent, and grind it thoroughly to make it evenly mixed. Add 10000 grams of diameter The zirconia balls of millimeters are milled in a horizontal ball mill with a milling speed of 130 rpm and a milling time of 16 hours. The ball-milled product was repeatedly washed 6 times with absolute ethanol, dried in vacuum at 45° C. for 8 hours, and finally pulverized. The flaky silver powder with D50 of 1.4 microns, D90 of 3.3 microns, Dmax ...

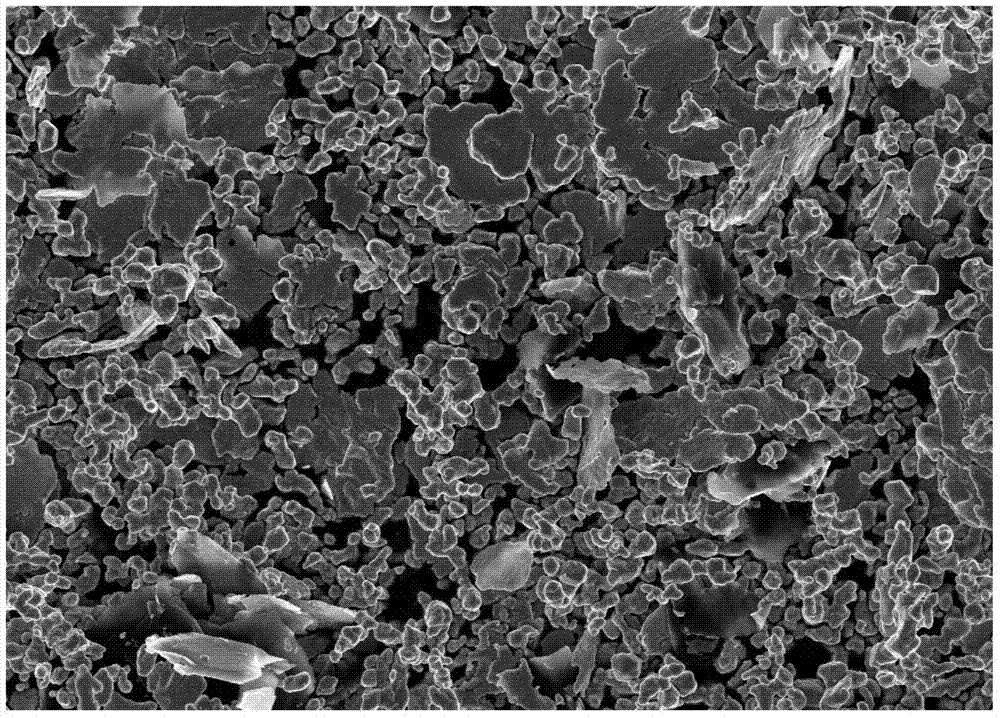

Embodiment 3

[0045] 1. Requirements: The silver content of the spherical or quasi-spherical ultrafine silver powder is 99.95-99.99%, and the particle size is 160-200 nanometers. The particle size of the conductive graphite powder is 1.5-50 microns, and the carbon content is 99.98-99.99%. The particle size of the modified conductive expanded graphite powder is 50-70 microns, and the carbon content is 99.98-99.99%. The diameters of the zirconia balls are mm and mm.

[0046] 2, take by weighing 1000 gram spherical silver powders, add 16.06 gram mass ratios and be conductive graphite powder: the mixture of conductive expanded graphite powder=2:1 after modification, 2.01 gram polyacrylic acid ball milling aids, 989.96 gram ethylene glycol ball milling solvents, Grind well to mix well. Add 6000 grams of mass ratio as The zirconia balls were ball milled in a horizontal ball mill with a ball milling speed of 180 rpm and a ball milling time of 10 hours. The ball-milled product was repeated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com