Method for adjusting asphalt mixture aggregate gradation by doping fine sands in desert

An asphalt mixture and fine sand technology, applied in the field of pavement paving materials, can solve the problems of inability of concrete to harden, decrease in strength performance, unreasonable maintenance conditions, etc., so as to make up for poor tensile performance, improve high temperature stability, and reduce oil flooding effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

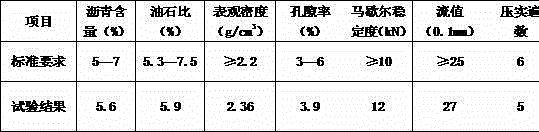

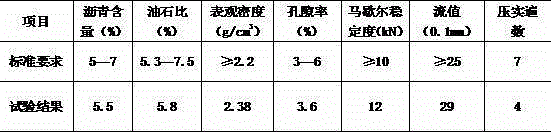

Embodiment 1

[0011] A method for adjusting the aggregate gradation of asphalt mixture mixed with fine sand in the desert according to the present invention. The components of the raw materials are composed according to the following mass percentages: asphalt content: 5.5%; asphalt ratio: 5.8%; 6.3-10mm crushed stone: 40 %; 4-6.3mm crushed stone: 10%; 0-4mm machine-made sand: 35%; fine sand in the desert: 10%; stone powder: 5%.

[0012] Mix desert sand, asphalt and gravel with a stabilized soil mixer or a forced mixer, and scrape out the road crown; use an oscillating roller or a vibratory roller to compact the above-mentioned mixture;

[0013] Upper layer: Sodium polyacrylate and water are prepared into a mixed solution in a mass ratio of 0.8:100 to 1.5:100, and left to stand for 12 hours; the slag wool fiber and the prepared mixed solution are mixed in a mass ratio of less than 1:10, Disperse for 2 minutes under the action of a high-frequency mixer; press filter the slag wool fibers in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com