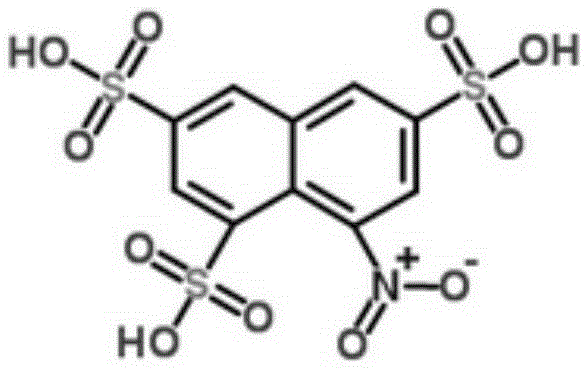

Technology for two-stage cross-flow extraction separation of mixed liquid of nitro T-acid, sulfuric acid and water

A cross-flow extraction separation and mixed liquid technology, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of low extraction efficiency, low product content, unfavorable T acid, etc., and achieve high economic benefits. The effect of high extraction efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

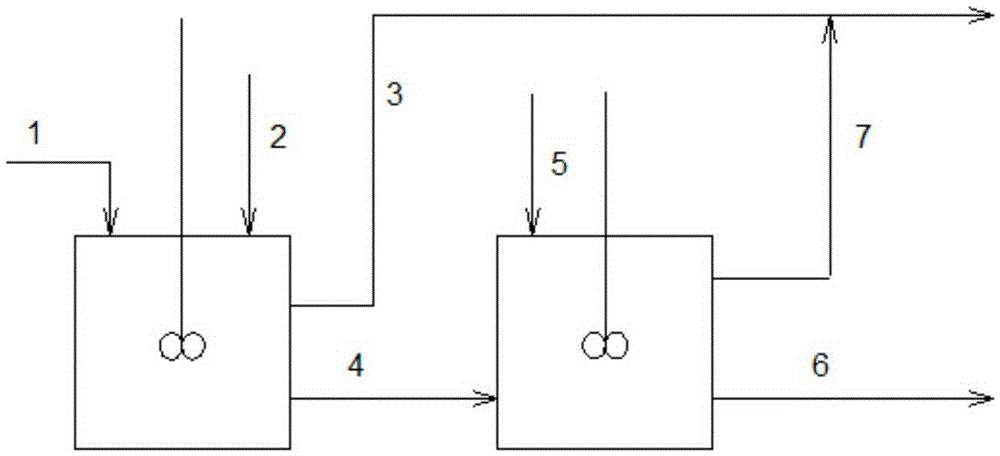

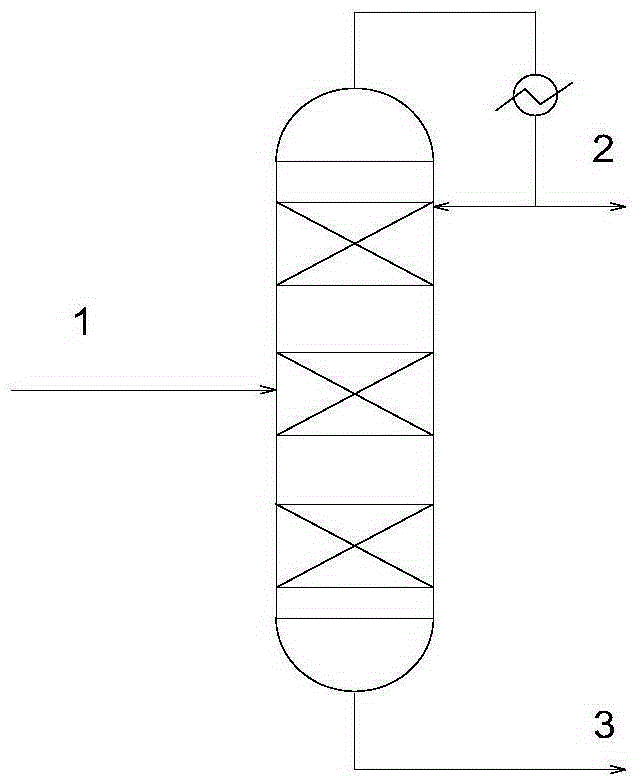

[0023] A process for two-stage cross-flow extraction and separation of nitro-T acid-sulfuric acid-water mixed solution, the extraction agent is prepared according to the mass ratio of tri-n-butylamine:benzene:n-butanol=7:2:1, with reference to figure 1 As shown in the process flow, the mixed liquid is subjected to two cross-flow extraction separations.

[0024] The specific flow of the first-stage cross-flow extraction process is: under normal temperature and pressure, the raw material is a mixed aqueous solution of 13.3% nitro-T acid concentration and 39% sulfuric acid, which is added to the first-stage extraction kettle, and then an extractant is added, and the raw material / solvent volume ratio It is 1:1, the mechanical stirring speed is 480r / h, stirring for 30min, standing for 30min, layering, and the raffinate phase enters the secondary extraction kettle. After the first-stage extraction, the concentration of nitro-T acid in the raffinate phase was 1.2 wt%, and the extract...

Embodiment 2

[0028] Using the same steps and conditions as in Example 1, two-stage cross-flow extraction was performed to separate the nitro-T acid-sulfuric acid-water mixed solution, wherein the mass ratio of tri-n-butylamine:benzene:n-butanol=5:4:1 Proportion to prepare extractant. The results are shown in Table 1 below.

Embodiment 3

[0030] Using the same steps and conditions as in Example 1, a two-stage cross-flow extraction was performed to separate the nitro-T acid-sulfuric acid-water mixed solution, wherein the mass ratio of tri-n-butylamine:benzene:n-butanol=6:3:1 Proportion to prepare extractant. The results are shown in Table 1 below.

[0031] Table 1 Results of first-stage cross-flow extraction and separation of complex extractants with different ratios (raw material / solvent ratio is 1:1)

[0032] Extractant ratio

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap