Preparation method and application of cross-linking type polymerization catalyst

A polymerization catalyst and cross-linking technology, which is applied in the field of preparation of cross-linking polymerization catalysts, can solve problems such as non-recycling and recycling, low catalyst loading capacity, and easy deactivation of catalysts, and achieve easy operation and easy post-processing , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

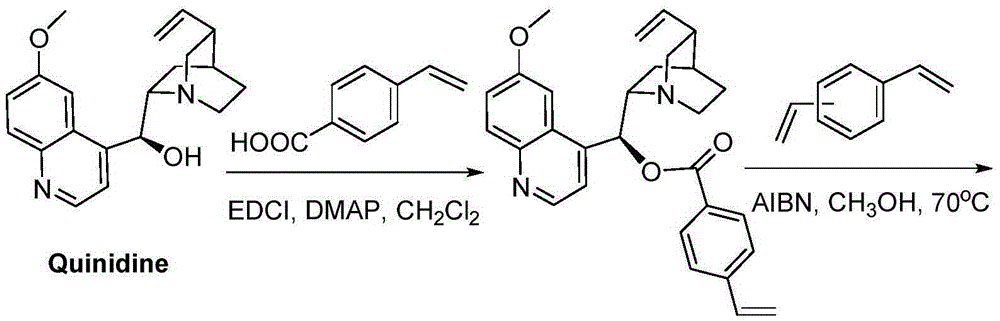

[0015] The first step: Weigh 2.04g p-vinylbenzoic acid and 0.52g 4-dimethylaminopyridine (DMAP) in 20ml dichloromethane, and then add 6.6g 1-(3-dimethylaminopropyl)-3-in three times Ethylcarbodiimide hydrochloride (EDCI), every 15 minutes, add 5.36g quinidine (Cinchonidine) solid at the end, carry out the esterification reaction at room temperature for 12h, spin off the solvent after the reaction, add 20ml Dichloromethane and an equal volume of distilled water, the separated aqueous phase was extracted twice with 40ml of dichloromethane, and the organic phases were combined and extracted once with 30ml of saturated brine. The extracted organic phase was dried with anhydrous sodium sulfate After filtration, concentration and silica gel column chromatography (EA:PE=1:5), a pale yellow oily compound was obtained as a catalyst precursor, and the yield was 86%.

[0016] Step 2: Weigh 0.91g of the catalyst precursor prepared above, mix 0.52g divinylbenzene and 0.043g azobisisobutyronit...

Embodiment 2

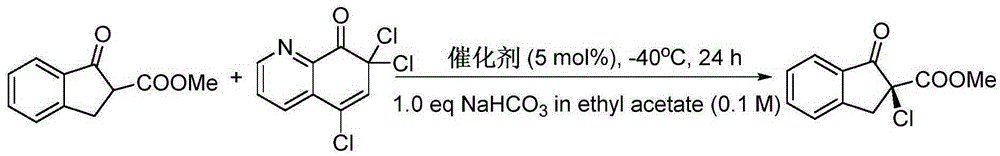

[0018] Weigh 0.015g (5mol%) of the catalyst prepared above, 0.076g β-ketoester (methyl1-oxo-2,3-dihydro-1H-indene-2-carboxylate) and 0.034g sodium bicarbonate dissolved in 4ml ethyl acetate After stirring for 10 minutes at -40°C, 0.150g of chlorinated reagent (5,7,7-trichloroquinolin-8(7H)-one) was added to carry out the asymmetric α-chlorination catalytic reaction of the following reaction structure:

[0019]

[0020] After the reaction, the catalyst was filtered out, and 10ml of distilled water was added. The separated aqueous phase was extracted twice with an equal volume of ether, and the organic phases were combined and extracted once with saturated brine. The extracted organic phase was dried, filtered, concentrated and silica gel The product obtained by column chromatography was α-chloroβ-ketoester, and its enantioselectivity was measured by high performance liquid chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com