A kind of radiative cooling double-layer nano-coating and preparation method thereof

A radiation refrigeration and nano-coating technology, applied in the field of spectrally selective nanoparticles, can solve the problems of not being suitable for large-scale industrial applications, difficult to control the preparation process, and poor refrigeration effect, and achieve maximum application value and refrigeration effect Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

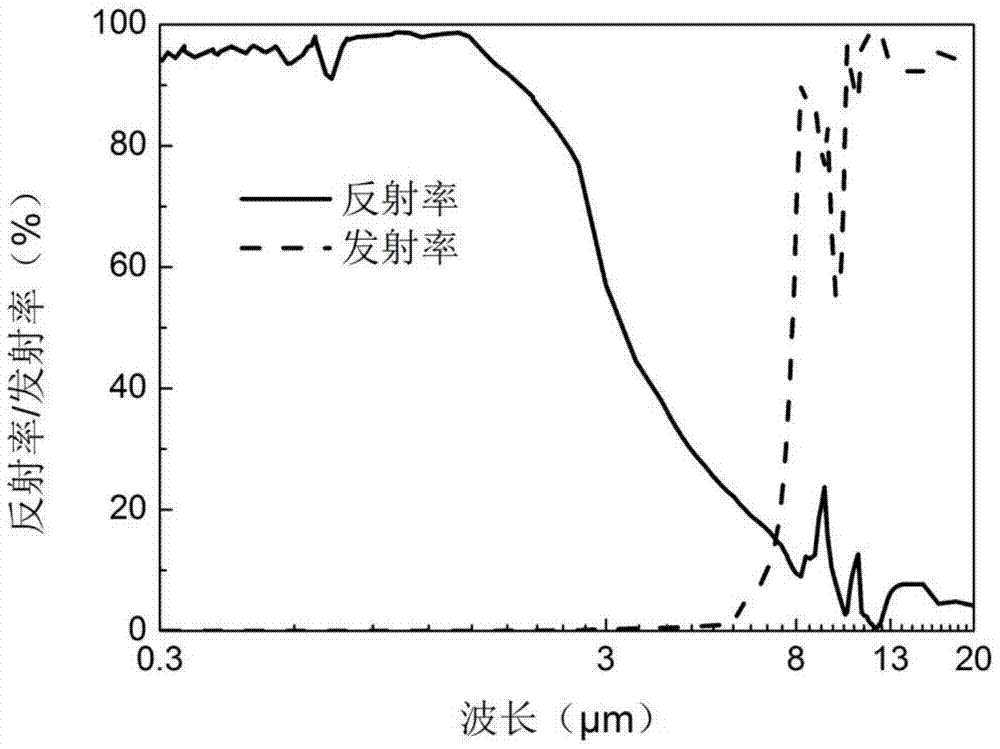

[0030] (1) Preparation of emission nano-suspension: Dissolve 5 mL of SiC nanoparticles with a particle size of 50 nm in 15 mL of isopropanol solution, and stir for 20 minutes with a magnetic stirrer at a speed of 500 r / min at room temperature to form a uniform SiC Nanosuspension;

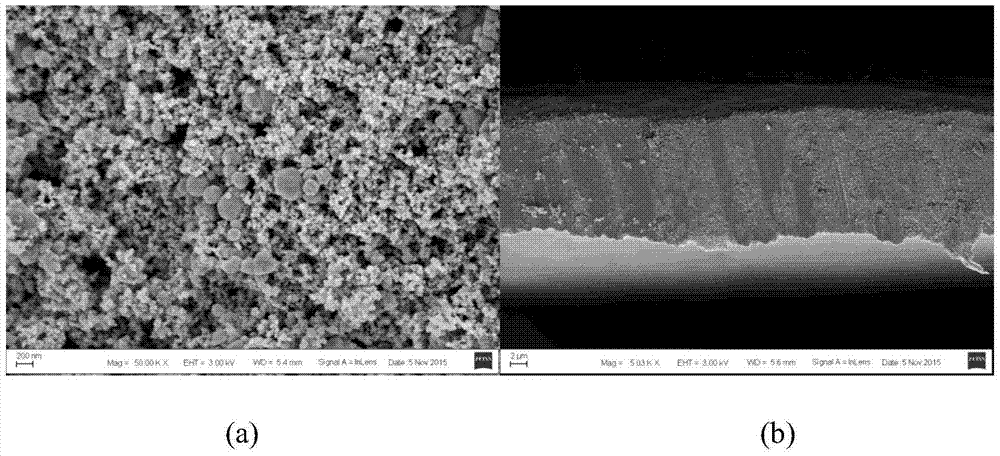

[0031] (2) Preparation of the emitting nanoparticle layer: pour the SiC nano-suspension into the Iwata spray gun W-77-G spray gun, and spray it on the upper surface of the aluminum foil. The bulk density can be controlled by controlling the number of sprays, spraying 10 times (about 10 μm ), placed in a cool place, until all the organic solvents are volatilized;

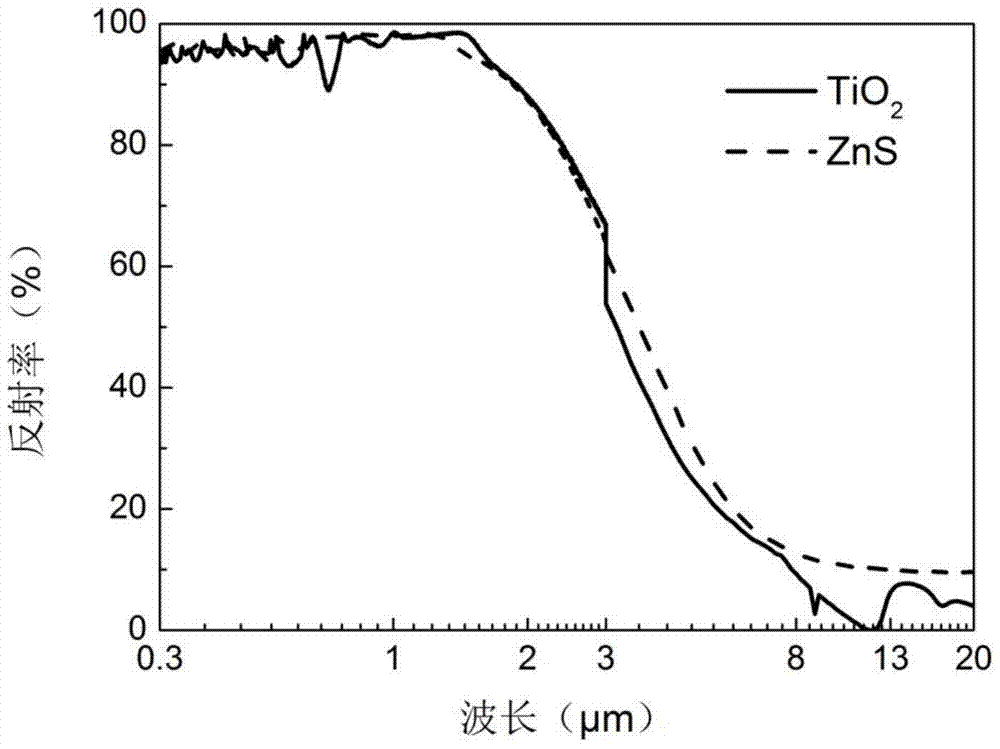

[0032] (3), 10mL of TiO with a particle size of 500nm 2 Nanoparticles were dissolved in 30mL isopropanol solution and stirred at room temperature with a magnetic stirrer at a speed of 500r / min for 20 minutes to form a uniform TiO 2 Nanosuspension;

[0033] (4), the TiO 2 Pour the nano-suspension into the Iwata spray gun W-77-G spray gu...

Embodiment 2

[0037] (1), the preparation of emitting nano-suspension is the same as Example 1;

[0038] (2) Pour the SiC nano-suspension into the Iwata spray gun W-77-G spray gun, and spray it on the upper surface of the aluminum foil. The bulk density can be controlled by controlling the number of sprays. Spray 20 times (about 20 μm), and put it in a cool place. Wait for the organic solvent to evaporate completely;

[0039] (3), 10mL of ZnS nanoparticles with a particle diameter of 500nm were dissolved in 30mL of isopropanol solution, and stirred for 20 minutes with a magnetic stirrer at a speed of 500r / min at room temperature to form a uniform ZnS nanosuspension;

[0040] (4) Pour the ZnS nano-suspension into the Iwata spray gun W-77-G spray gun, and spray it on the upper surface of the emitting nanoparticle layer. The bulk density can be controlled by controlling the number of sprays, spraying 40 times (about 40 μm);

[0041] (5) Place the prepared sample in a cool and ventilated place...

Embodiment 3

[0044] (1) Preparation of emission nanosuspension: weigh 1mL of SiC nanoparticles and 1mL of SiO 2 Nanoparticles, mixed and dissolved in 10mL of isopropanol solution, stirred at room temperature with a magnetic stirrer at a speed of 500r / min for 20 minutes to form a uniform nanosuspension;

[0045] (2), preparation of emission nanoparticle layer: pour the nanosuspension of mixed particles into Iwata spray gun W-77-G type spray gun, and spray on the upper surface of aluminum foil, the bulk density can be controlled by controlling the number of spraying times, spraying 20 times ( About 20μm), put it in a cool place and volatilize the organic solvent;

[0046] (3), 10mL of TiO with a particle size of 500nm 2 Nanoparticles were dissolved in 30mL isopropanol solution, and stirred at room temperature with a magnetic stirrer at a speed of 500r / min for 20 minutes to form a uniform TiO 2 Nanosuspension;

[0047] (4), the TiO 2 Pour the nano-suspension into the Iwata spray gun W-77-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com