PVA derivative radiation refrigeration film material as well as preparation method and application thereof

A radiative refrigeration and derivative technology, which is applied in refrigerators, refrigeration and liquefaction, climate change adaptation and other directions, can solve the problem that there is no multilayer porous PVA derivative film, and achieves good cooling effect, easy availability of raw materials and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1. Preparation of PVA-C8 film

[0063] (1) Preparation of PVA-C8:

[0064] Take 5.0g of PVA powder in a 250mL round bottom flask, add 200mL of dry dimethyl sulfoxide (DMSO) solution, heat to dissolve at 90°C. The obtained PVA solution was cooled to 60° C., then p-toluenesulfonic acid monohydrate (0.432 g) was added rapidly, and stirred for 1 h. Subsequently, 7.3 mL of octanal was added dropwise to the activated PVA solution, and stirring was continued for 1 h. Pour into saturated sodium bicarbonate solution, stir, and precipitate. Cut the above sediment into pieces, change the water to wash, repeat this process for at least 3 days, and change the water three times a day. Finally, the white powder PVA-C8 was obtained by freeze-drying.

[0065] (2) Preparation of PVA-C8 film:

[0066] PVA-C8 powder was dissolved in N,N-dimethylformamide (DMF) at 90° C. at 15 wt %, and stirred for 7 h to obtain a homogeneous solution with a mass fraction of 15 wt %. The solution was ...

Embodiment 2

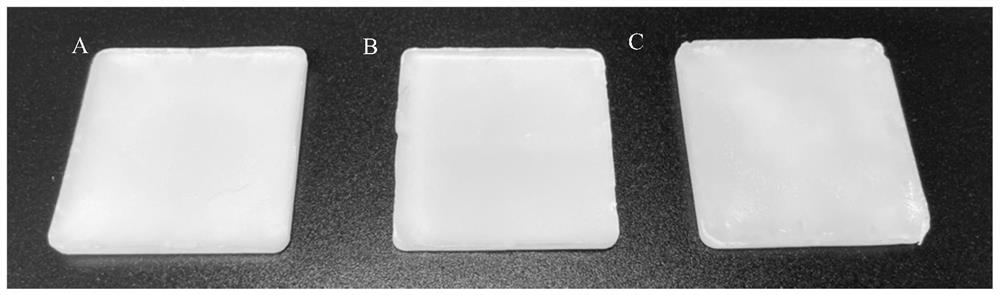

[0075] The morphology of PVA-C8 thin film, PVA-C6 thin film and PVB thin film synthesized by phase separation method in embodiment 1 is as follows figure 1 shown. From figure 1 It can be seen that the PVA-C8 film is whiter than the PVA-C6 film and PVB film, indicating that it has the strongest scattering effect on light and is more in line with the requirements of radiation cooling.

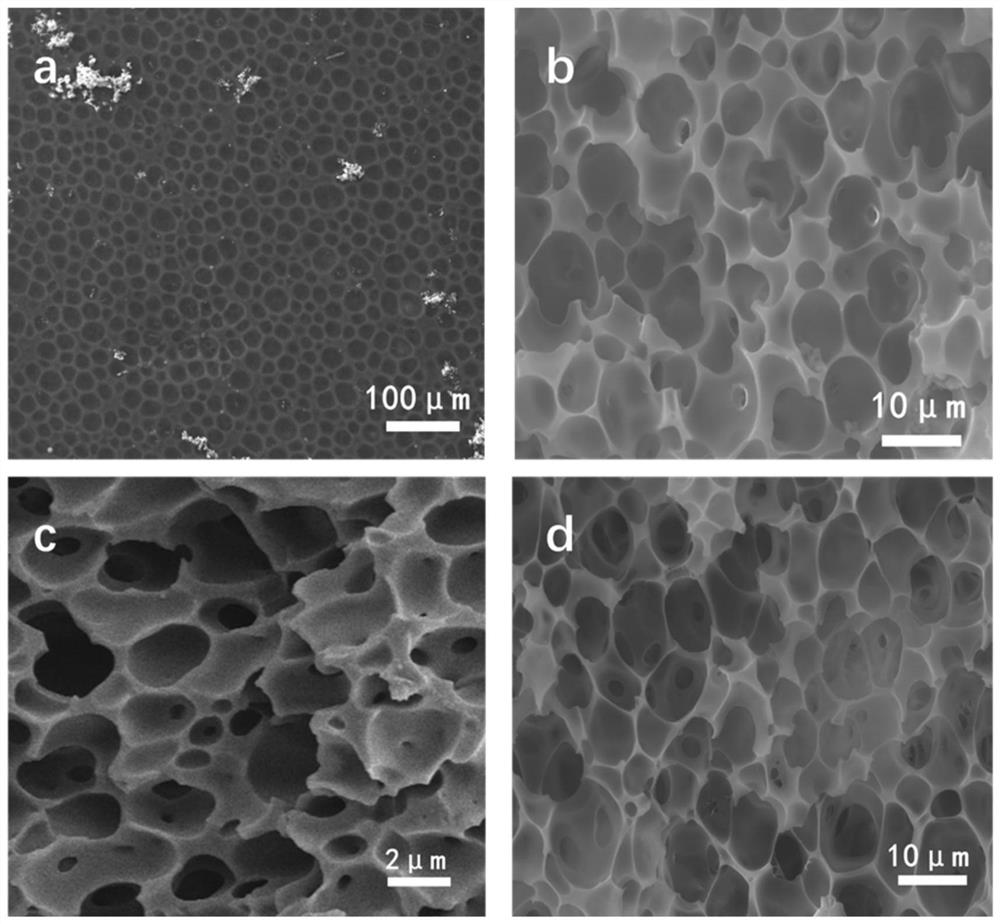

[0076] The scanning electron microscope (SEM) observation result of PVA-C8 thin film is as follows figure 2 Shown: It can be seen from the SEM image that there are many holes on the surface of the PVA-C8 film, and the inside is filled with holes of 0.4-3 μm. This structure rich in holes is conducive to light scattering.

Embodiment 3

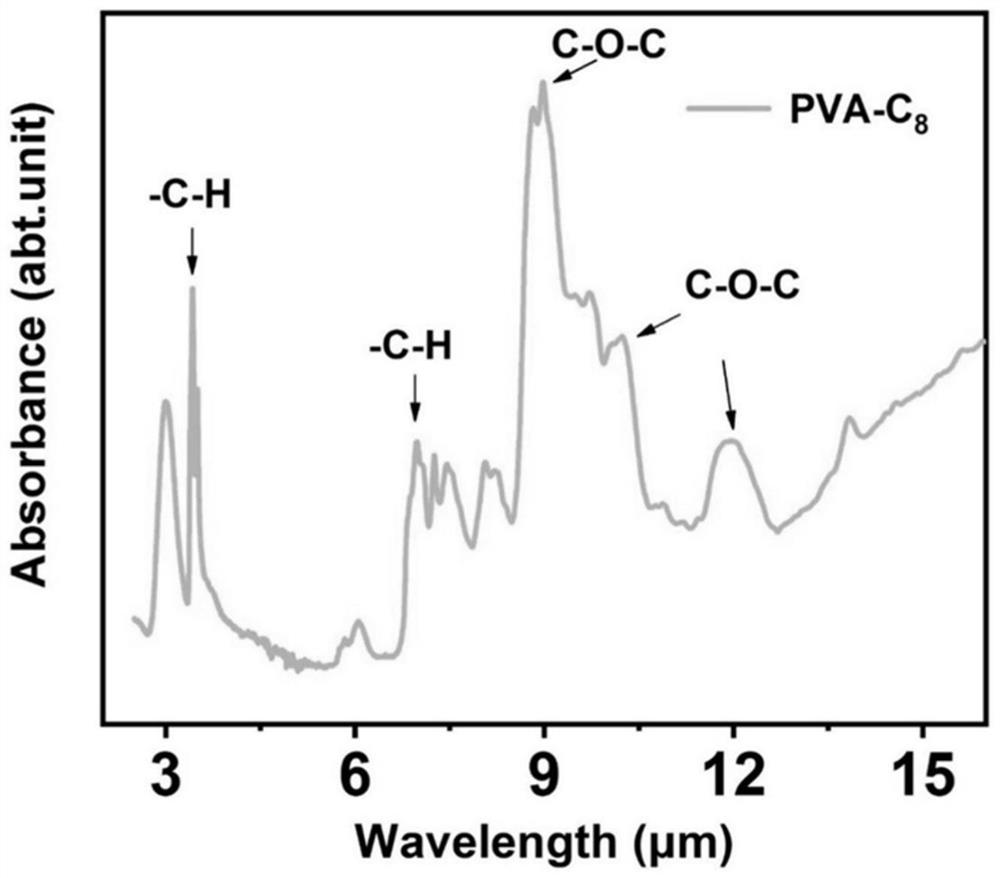

[0078] Adopt ATR-FTIR spectrometry to measure the absorbance of the PVA-C8 thin film synthesized in embodiment 1, the result is as follows image 3 Shown: It can be seen from the figure that there are absorption peaks at 8-13 mm, mainly -OH association and C-H, C-O and C-O-C stretching vibration peaks, which are just located in the transparent window of the atmosphere, resulting in a strong thermal emissivity of the PVA-C8 film. The high emissivity in the infrared spectrum leads to radiative heat exchange between the polymer film and the atmosphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com