Blue ceramic pigment with high sunlight reflectance ratio and preparation method thereof

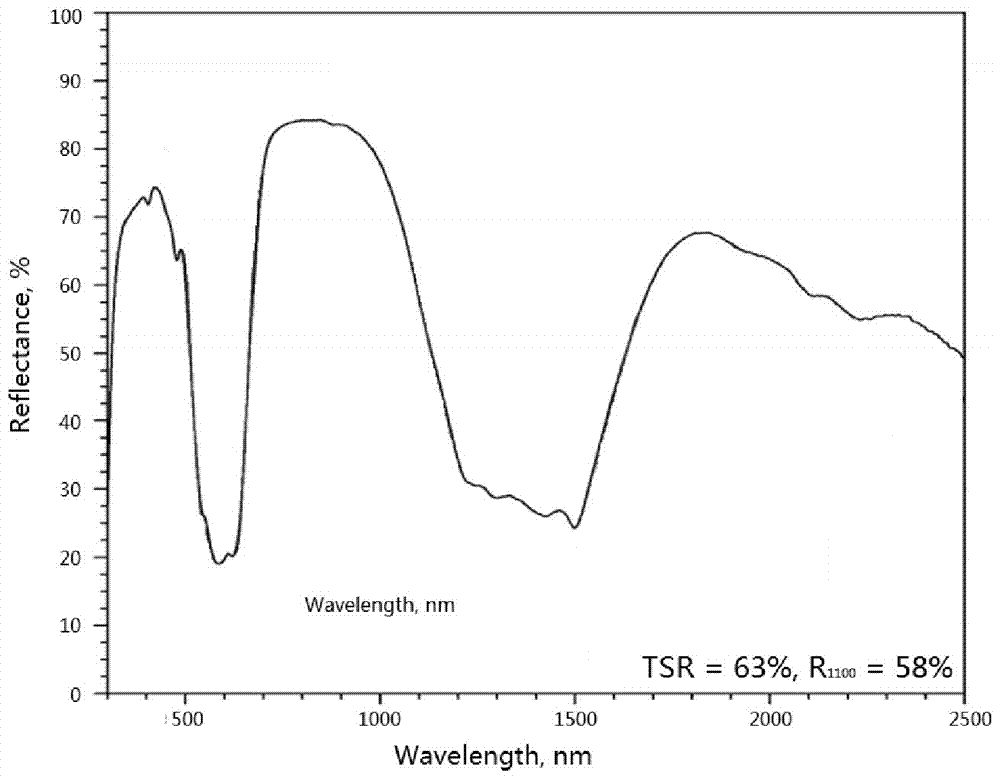

A technology of ceramic pigments and solar light, applied in the direction of fibrous fillers, etc., can solve the problems of environmental pollution, expensive raw materials, high energy consumption, etc., and achieve the effects of economical preparation cost, high solar reflectance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A kind of preparation method of the blue ceramic pigment with high sunlight reflectance of the present invention, this preparation method specifically comprises following operation steps:

[0019] Step (1), preparation of raw material mixed solution: take zinc nitrate tetrahydrate, cobalt nitrate hexahydrate, aluminum nitrate nonahydrate, glycine, respectively adopt deionized water to dissolve into saturated solutions and mix each saturated solution with urea to control nitric acid tetrahydrate The molar ratio of zinc, cobalt nitrate hexahydrate, aluminum nitrate nonahydrate, glycine and urea is 81:9:180:100:675; stir at 80°C for 30-40 minutes to obtain a raw material mixture;

[0020] Step (2), product synthesis: heating the obtained raw material mixture to above 300°C, the system undergoes a self-propagating combustion reaction, and after the reaction is completed, naturally cool to room temperature to obtain the crude product;

[0021] Step (3), product purification:...

Embodiment 1

[0025] Weigh each substance according to the following mass and make corresponding saturated solution:

[0026] 235.3g Zn(NO 3 ) 2 4H 2 O, dissolved in 421g deionized water;

[0027] 29.1g Co(NO 3 ) 2 ·6H 2 O, dissolved in 33.5g deionized water;

[0028] 750.3g Al(NO 3 ) 3 9H 2 O, dissolved in 963.7g deionized water;

[0029] Glycine 84.1g, dissolved in 336.3g deionized water;

[0030] The prepared above saturated solution and 450.5 g of urea were placed in a 2.5 liter mixed glass vessel, and stirred at 300 rpm for 30 minutes at 80°C to obtain a raw material mixture;

[0031] The obtained raw material mixture is heated. During the heating process, as the temperature rises, the water in the raw material mixture volatilizes, and the viscosity of the system increases. When the raw material mixture is heated to 290°C, the raw material mixture is ignited and a self-propagating combustion reaction occurs, during which a large number of reactions are accompanied. Heat and...

Embodiment 2

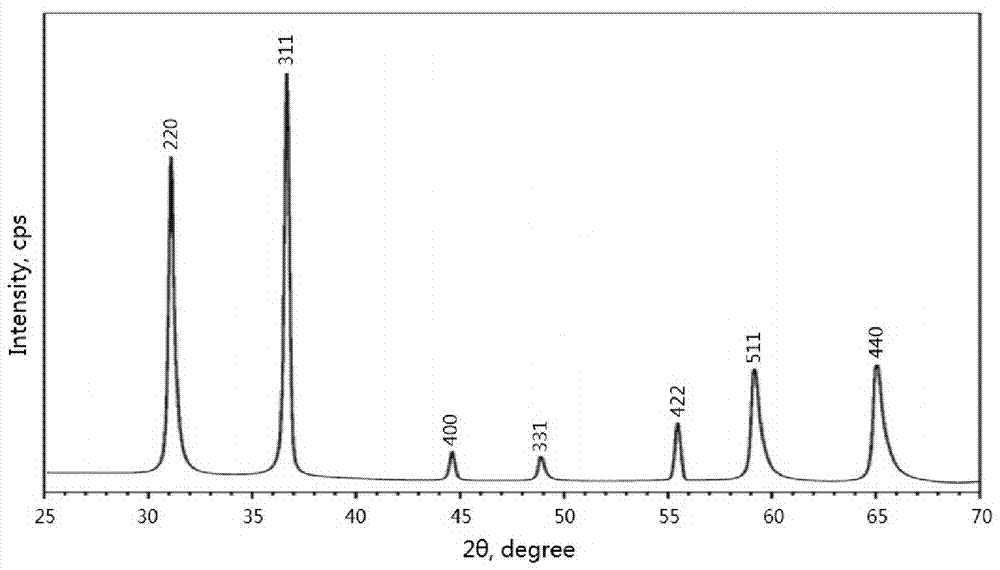

[0034] The product prepared in Example 1 is subjected to X-ray diffraction to obtain the XRD spectrum of the product, as figure 1 shown; will figure 1 and ZnAl 2 o 4 Compared with the standard spectrum 01-070-8181, it is found that the product has crystal ZnAl 2 o 4 of all diffraction peaks, therefore, the product has ZnAl 2 o 4 (01-070-8181) in the spinolite crystal form; and due to figure 1 There are only diffraction peaks of zinc aluminate and no other miscellaneous peaks, indicating that Co has been well doped into ZnAl 2 o 4 In the crystal, the molecular composition of the product is Zn 0.9 co 0.1 Al 2 o 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com