Outdoor low-heat-absorption inorganic artificial stone plate and preparation method thereof

An artificial stone slab and inorganic technology, applied in the field of artificial stone, can solve the problems of low heat reflectivity, high heat absorption, and low heat absorption, and achieve the effects of high sunlight reflectivity, low heat absorption, and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

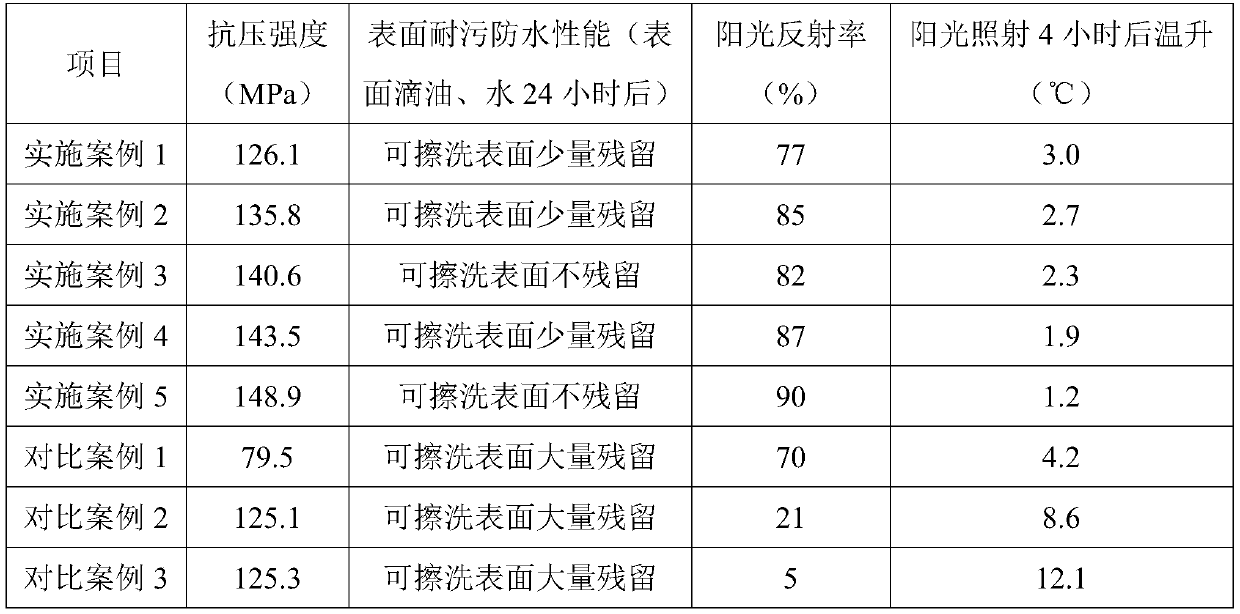

Examples

Embodiment 1

[0028] An outdoor low-heat-absorbing inorganic artificial stone slab is prefabricated from ultra-high-performance mineral powders with a compressive strength of 100-150 MPa, and the ultra-high-performance mineral powders include the following raw material components in parts by weight: quartz 90 parts of sand, 15 parts of quartz powder, 40 parts of quartz glass, 80 parts of mineral active powder, 4 parts of titanium dioxide, 10 parts of water, 2 parts of water reducing agent, and 3 parts of pigment.

[0029] The activity index of the mineral active powder is not less than 110%. The main body is cement with a value of 42.5 or more, and silica fume, mineral powder, glass microspheres, ceramic polishing powder, aluminum hydroxide powder and zeolite powder are added. The mass ratio of mineral active powder components is cement: silica fume: mineral powder: glass beads: ceramic polishing powder: aluminum hydroxide powder: zeolite powder is 1: 0.125: 0.75: 0.15: 0.1: 0.075: 0.1.

[...

Embodiment 2

[0042] Except that the formulation of the ultra-high performance mineral powder is different, other conditions are the same as in Example 1.

[0043] An outdoor low-heat-absorbing inorganic artificial stone slab is prefabricated from ultra-high-performance mineral powders with a compressive strength of 100-150 MPa. The ultra-high-performance mineral powders include the following raw material components in parts by weight: quartz 120 parts of sand, 30 parts of quartz powder, 60 parts of quartz glass, 100 parts of mineral active powder, 15 parts of titanium dioxide, 18 parts of water, 5 parts of water reducing agent, and 10 parts of pigment.

Embodiment 3

[0045] Except that the formulation of the ultra-high performance mineral powder is different, other conditions are the same as in Example 1.

[0046]An outdoor low-heat-absorbing inorganic artificial stone slab is prefabricated from ultra-high-performance mineral powders with a compressive strength of 100-150 MPa, and the ultra-high-performance mineral powders include the following raw material components in parts by weight: quartz 100 parts of sand, 19 parts of quartz powder, 45 parts of quartz glass, 85 parts of mineral active powder, 7 parts of titanium dioxide, 12 parts of water, 3 parts of water reducing agent, and 5 parts of pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com