Method for preparing docosahexenoic acid from schizochytrium sp.

A technology of docosahexaenoic acid and Schizochytrium, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve time-consuming and labor-consuming, serious secondary pollution, Schizochytrium Inability to grow and other problems, to achieve the effect of low cost, low cost, and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

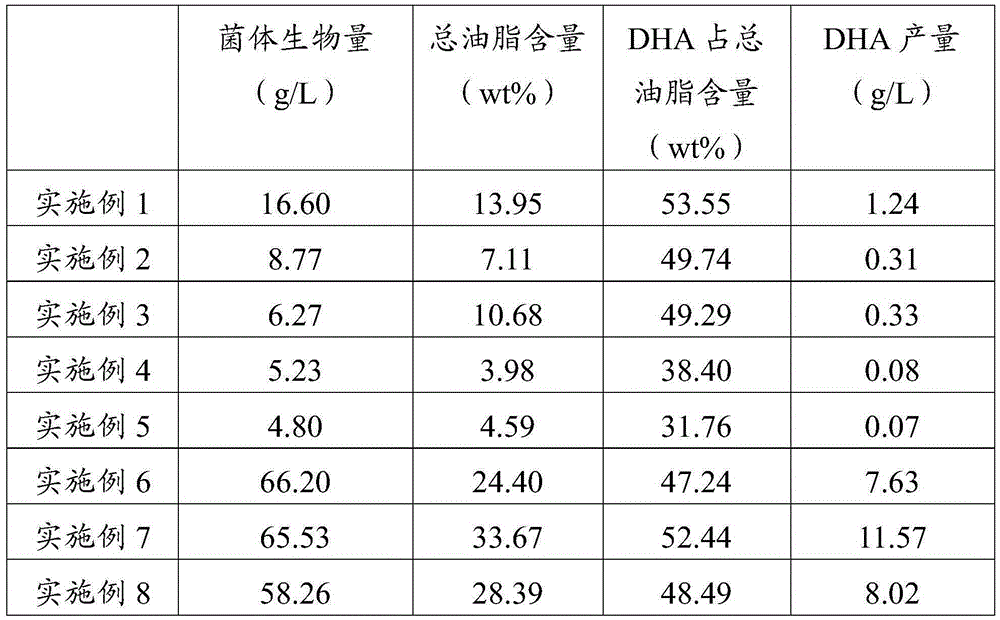

Examples

preparation example 1

[0045] The preparation method of bagasse hydrolyzate comprises the following steps:

[0046] (1) Take the bagasse after sugar extraction, place it in a blast drying box, and dry it for 3 days at 60°C until its water content is lower than 5wt%;

[0047] (2) pulverize the dried bagasse with a pulverizer, and sieve to obtain bagasse powder with a particle diameter of 2 to 20 mm;

[0048] (3) Mix bagasse powder with 0.01mol / L H 2 SO 4 The solution was mixed according to the solid-to-liquid ratio of 1:6, reacted at 120°C for 60 minutes, filtered, and the filtrate was Ca(OH) 2 Adjust the pH to 5, let stand for 1 hour, and filter to obtain bagasse hydrolysis stock solution.

preparation example 2

[0050] The preparation method of bagasse hydrolyzate comprises the following steps:

[0051] (1) Take the bagasse after sugar extraction, place it in a blast drying box, and dry it for 2 days at 80°C until its water content is lower than 5wt%;

[0052] (2) pulverize the dried bagasse with a pulverizer, and sieve to obtain bagasse powder with a particle diameter of 2 to 16 mm;

[0053] (3) Mix bagasse powder with 0.02mol / L H 2 SO 4 The solution was mixed according to the solid-to-liquid ratio of 1:3, reacted at 150°C for 120min, filtered, and the filtrate was Ca(OH) 2 Adjust the pH to 7, let stand for 1 hour, and filter to obtain bagasse hydrolysis stock solution.

preparation example 3

[0055] The preparation method of bagasse hydrolyzate comprises the following steps:

[0056] (1) Take the bagasse after sugar extraction, place it in a blast drying oven, and dry it for 2.5 days at 70°C until its water content is lower than 5wt%;

[0057] (2) pulverize the dried bagasse with a pulverizer, and sieve to obtain bagasse powder with a particle diameter of 2 to 15 mm;

[0058] (3) Mix bagasse powder with 0.01mol / L H 2 SO 4 The solution was mixed according to the solid-to-liquid ratio of 1:8, reacted at 140°C for 200min, filtered, and the filtrate was Ca(OH) 2 Adjust the pH to 6, let stand for 2 hours, and filter to obtain bagasse hydrolysis stock solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com